PADT has been providing various forms of rapid prototyping since 1994, focused on providing high quality prototypes to engineers involved in product development. Over that time, we have learned a lot about what our customers need to know in order to get the most out of their rapid prototyping investment. As we launch our new The RP Resource, we think now is a good time to share some of the things we have learned.

1: Know what you are going to use your prototype for

This is the most important thing for any engineer to know when they are using rapid prototyping. A good understanding of how the prototype will be used is critical to making decisions on the technology applied, the material used, the build options set, and the post processing that is carried out. When we look into why a customer who is unhappy with their prototype, nine times out of ten we find out that they did not convey to us what their end use was, so we did not make them the prototype they actually needed.

2: Rapid Prototyping, Direct Digital Manufacturing, 3D Printing: They are all additive manufacturing

The technology may vary from machine to machine, but in the end they all kind of work the same – they build a part one thin layer at a time. This is important because the part you end up getting will be made with layered manufacturing. The strength will be non-uniform, features that overhang may droop a bit if not properly supported, and the surface finish will not be smooth unless you chemically treat it or sand it after the build is done.

3: You will get an exact copy of your STL or CAD file, so make sure it is a good one.

The prototype that you are making is a direct digital copy of the file you ask it to print. None of the processes improve on the geometry you send to them, so it is important that you provide a high quality model. If you are starting with an STL file, you need to make sure that you have enough facets on your model so that they are not visible on the prototype. We like the maximum deviation of the facet from the actual shape (chord height) to be less than 0.001 inches. We recently did a post on this very topic.

The same goes true for “bad” STL files. You may get errors, or the prototyping system may not even be able to build your part. Making sure you have a quality STL or CAD will save everyone a lot of time.

4: Build orientation has a big impact on cost, surface quality, and strength

Remember that you are using a layered manufacturing process. The number of layers and their orientation relative to your part can make a bid difference on cost, the surface quality, and strength.

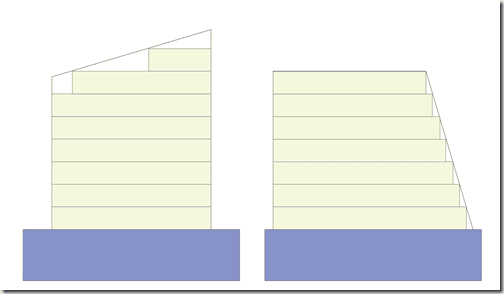

In the exaggerated illustration above, you can see the same shape will have different stepping, and a different number of layers depending on how it is oriented. The taller the part, the longer it takes to build. The lower the slope, the more “stair-stepy” the surface.

Something else to take into account is that the parts will be weaker when the layers are put under load that causes them to delaminate. Imagine your prototype was made up of a deck of stacked playing cards with a glue between each card. You want to load it in a way that will not cause those cards to want to pull apart.

5: The amount of material in you part is a big cost driver

One of the biggest drivers of the cost on a prototype is the amount of material used to build the part. This is especially true when you are using some of the more expensive materials. Take a look at using options in your machine software to more sparsely filled part. You can also shell your part on your CAD system. If you are working with a service provider, ask them to take a look at this on your prototypes.

6: Part geometry can come from CAD, or a scan

Customers occasionally come to us with an existing part and ask us to make a CAD model of it so they can prototype it. In some cases, it may be easier to just make some soft tooling of the part, skip the prototyping process entirely. But if that does not work, you can use a variety of scanning technologies to get a faceted representation of the real part.

7: Warping and shrinking distortion is above and beyond published machine accuracy

When you look at the published accuracy of a given machine what they show you is the accuracy of the process that traces an outline or sets the thickness of a layer. The accuracy of the mechanisms in the machine itself. Your part may have much less accuracy because most parts warp and shrink slightly during the manufacturing process. Overhangs may also droop if they are not supported correctly.

The key to solving this problem is to really know the machine you are using, or work with a service provider who knows how to plan for and adapt to this reality. Some technologies may just not be suited for your geometry, and you may need to go with a different machine type.

8: Build the full cost or prototyping into your product developments budget

People who use prototyping effectively in their product development always budget for the proper amount to pay for prototyping. Too often this important tool is left out of the budget and when a prototype is needed, funding can not be found or shortcuts are taken that diminish the value of the prototypes. In order to do things right the first time, you should plan for the expense.

9: You are not stuck with the material color that the part is made with

It is fairly easy and affordable to paint or dye most rapid prototyping parts. It does add time to the project because painting or dyeing takes time. Users should be aware that they can get almost any color they need on their part. A talented technician can also provide almost any surface finish that is needed.

10: Your prototype can be used as a pattern for casting multiple parts

If you need multiple copies of your part, it may be more affordable to only make one additive manufacturing part and then use soft tooling to make copies. This is also a way to get material properties that are not available with any of the additive manufacturing technologies. In some cases, you can even cast injection molding tooling from a prototype part.

11: The quoted price of the prototype is just part of the total cost of having a prototype made

When looking at cost it is important to calculate the total cost. When doing rapid prototyping you need to look at the quoted price of having a prototype made, internally or externally, as only one of many costs. Other activities that impact total cost are: cost of reworking prototypes; shipping/delivery costs; delay in schedule due to build, post processing, and shipping time; time and money spent modifying tests to fit the prototypes shortcomings, time and cost required to deal with prototype failures, etc…

12: Take some time to learn the strengths and weaknesses of every available technology

Even if you have one particular technology any engineer who needs to do a significant amount of rapid prototyping should invest the time in understanding all of the available technologies. Each has advantages and disadvantages, and if you understand them and you understand what the usage of your prototype will be, you can save yourself and your company a lot of time and money by choosing the proper technology for each prototypes.

We hope to have some time in the coming months to provide some in depth information on all of the major prototyping technologies, so check this blog for more information.