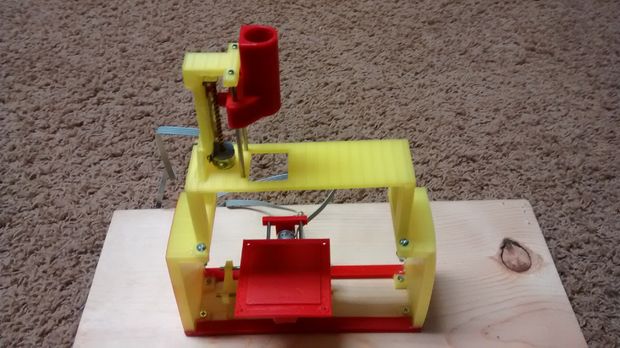

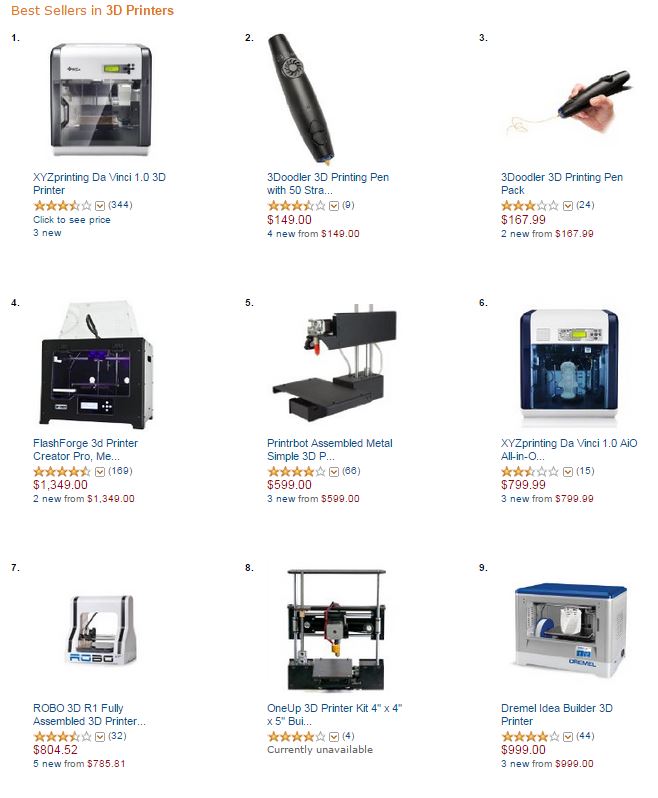

So this 17 year old kid used his 3D Printer, an arduino board and parts he scrounged from old DVD drives to make a 3D Printer. Read about it here. This kid, wootin24, designed and built an X, Y, Z positioning device that could be fited with a dremel tool to be a CNC machine, or an extruder to be a 3D Printer. No CAD experience, no formal engineering training, just a smart person. And the ad that popped up on the side of the how-to this kid wrote was for a Dremel 3D Printer, available at Home Depot. Not some kickstarter funded rehash of an opensource printer, Dremel. The big guys. As I was feeling bad about how I spent my time when I was 17 (I’m not going to go there but I never did become a the backup bass player for Rush nor did I get a second date from T—–) and starting to worry about how systems from very capable companies like Dremel will impact our sales of Stratasys equipment, I realized that the true revolution in 3D printing happened and most of us involved day-to-day in the industry didn’t even notice.

3D Printing is Now Normal

When a revolutionary technology comes out there is a lot of hoopla and press. Tons of people start jumping on the bandwagon and your Aunt’s friend in Topeka is sending you links on Facebook about 3D Printing and how it is “going to change everything.” Do not get me started on how 3D Printing is not new, we’ve been doing it at PADT for over 20 years, and certainly do not ask about the “3D printed gun. The false-newness and fear-mongering stories are what the mainstream press picked up on. The good news is that the hype got the word out. And then smart people like this kid and the engineers at Dremel said “hmmm, that is useful. I can do something with this” and boom, the real revolution happened.

After all these years this tool that was really a special tool used when needed, has become just another screwdriver in the toolbox. A standard part of the process it is something most engineers understand well, and a majority of non-engineers are aware of. When we first started showing people our SLA machine back in the 90’s they would either not understand what they were looking at or become flabergasted and amazed, treating it more like a magic box than a fairly simple additive curing system. Now when we give tours we hear “that one looks like the one we have in our office” or “oh yea, an Objet, I’d love to trade my older system in for one of those.” And the dreaded “oh, we have three of these in our robotics lab at school, do you have anything interesting?”

So What

There is a lot of power in 3D Printing. That is the real reason why the technology has blossomed as it has. The power of 3D Printing is that it lets you make physical objects without special equipment or knowledge, the laser printer of manufacturing. However, as long as the tool is treated as something to be used in special cases or as a mystical new magic bullet, it will not be used correctly. Now that it is mainstream, the use of additive manufacturing becomes mainstream and the power it brings to the table can be fully realized. We see this every day at PADT. Product managers have “3D Printed Prototypes” as a standard line item in their budget templates. Customers are increasingly talking about going back to their current product lines and identifying parts that are machined, injection molded, or cast and determining which can be replaced by 3D printed parts. And most importantly, the supply chain and quality people are sniffing around and starting to make paperwork to control and manage 3D Printed components.

As proponents of the technology since the early days, we could not be happier than when we see a check box for “Created with additive manufacturing” on a quality form. When it becomes part of the bureaucracy, the revolution has truly happened.