Every once in a while a customer hits a home run with Additive Manufacturing, and United Launch Alliance had done that with their application of Stratasys technology to the production of flight-ready components for their rockets. They were able to leverage 3D printing to take one component from 140 parts to 16, reducing the risks associated with creating the assembly, the piece part costs, and the assembly cost. And PADT is proud to say we were partners in this effort with ULA and Stratasys.

If you are not familiar with ULA, they are the world’s premier launch service company in the US. It is a joint venture of Boeing and Lockheed that launches the majority of military and civilian payloads that are sent into space. True “rocket scientists” who are headquartered down the street from PADT’s Littleton, Colorado office. They just released a ton of information on how they are using the Stratasys devices they acquired through PADT as an example of what the technology can achieve.

Stratasys just released a great video on how ULA is using the technology. This is a great example of the right people, using the right technology, in the right way

You can also read the official press release here.

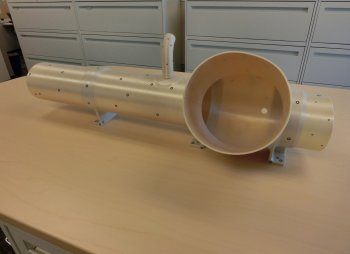

We are highlighting his application as a way to let people know that 3D Printing is not just about makers, nor is it just about engineering prototypes. Every day users are creating production hardware to produce usable parts that save them time and money. Ducts for rockets are a perfect use of the technology because they are complex, low volume, and can make single parts that need to be made in multiple pieces using traditional methods. This application also highlights the power of the material choices available to users of Stratasys FDM technology. ULA is using ULTEM 9085 for these ducts because it is durable, lightweight, and can stand up to the heat of the launch event.

Those of you familiar with the process will notice the dots on the duct. Those are target dots for 3D scanning. ULA took the technology one step further and scan the completed hardware to make sure the manufactured part is within specifications.

The team at ULA has been a pleasure to work with. They saw the promise of Additive Manufacturing but dealt with it like the seasoned professionals that they are. They started by making engineering prototypes, then as they got a feel for the technology they switched to the production of tooling for manufacturing. They have now developed the confidence needed to move to flight hardware. In addition to supplying the machines, PADT consulted with ULA early on, touring their manufacturing facilities to better understand their needs and taking them to see how others are using FDM for manufacturing. We were fortunate enough to even be invited to attend the launch of their Orion spacecraft from Florida as their guest.

We are very excited about the additional uses ULA and other companies will develop in the near future for Additive Manufacturing.

If you want to know more, or would like to have PADT help you in the same way we assisted ULA, please reach out or email info@padtinc.com.