The developers of Flownex have been hard at work again and have put out a fantastic update to Flownex 2015. These additions go far beyond what most simulation programs include in an update, so we thought it was worth a bit of a blog article to share it with everyone. You can also download the full release notes here:

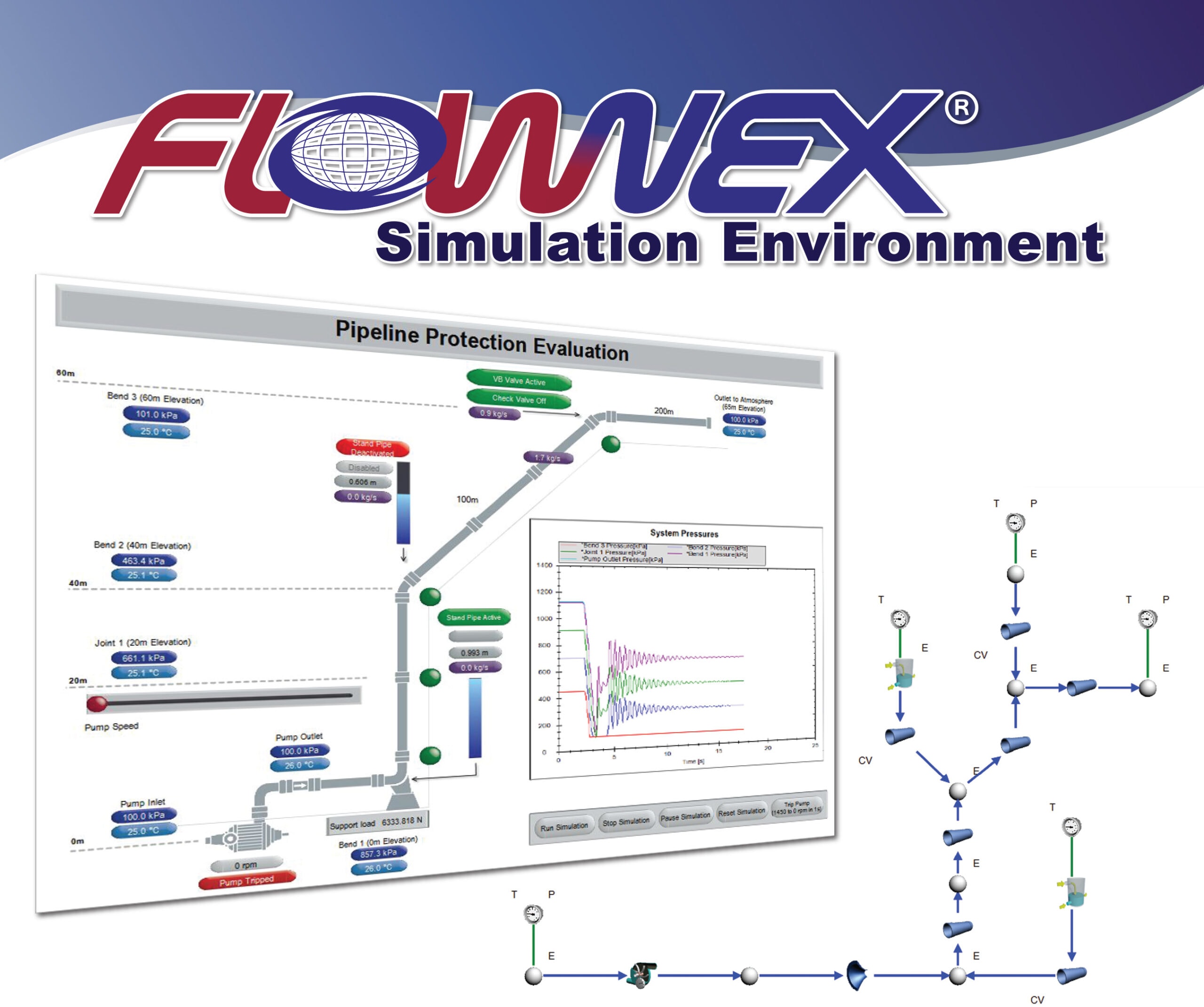

What is Flownex?

Some of you may not be familiar with Flownex. It is a simulation tool that models Fluid-Thermal networks. It is a 1-D tool that is very easy to use, powerful, and comprehensive. The technology advancements delivered by Flownex offer a fast, reliable and accurate total system and subsystem approach to simulation that complements component level simulation in tools like ANSYS Fluent, ANSYS CFX, and ANSYS Mechanical. We use it to model everything from turbine engine combustors to water treatment plants. Learn more here

Major Enhancements

A lot went into this update, much hidden behind the scenes in the forms of code improvements and fixes. There are also a slew of major new or enhanced features worth mentioning.

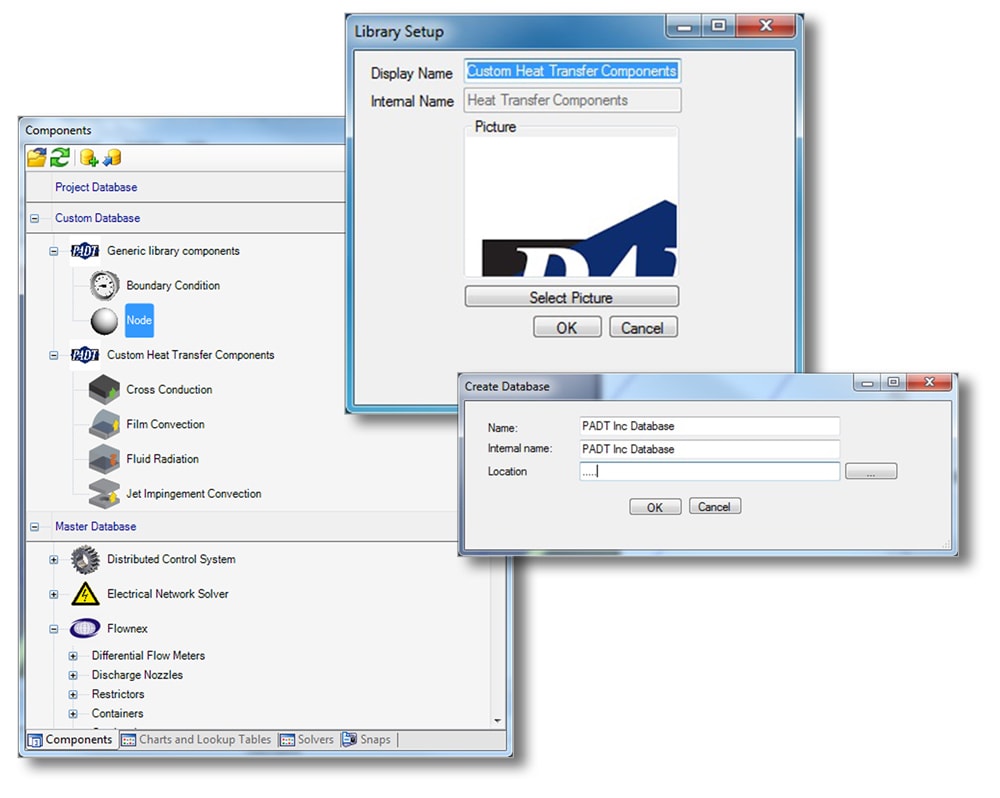

Shared Company Database

One of the great things about Flownex is that you can create modeling objects that you drag and drop into your system model. Now you can share those components, fluids, charts, compounds, and default settings across your company, department, or group. There is no limit on the number of databases that are shared and access can be controlled. This will allow users to reuse information across your company.

Static Pressure Boundary Conditions

In the past Flownex always used a total pressure boundary condition. Based on user requests, this update includes a new boundary condition object that allows the user to specify the static pressure as a boundary condition. This is useful because many tests of real hardware only provide static pressure. It is also a common boundary condition in typical rotational flow fields in turbo machinery secondary flow.

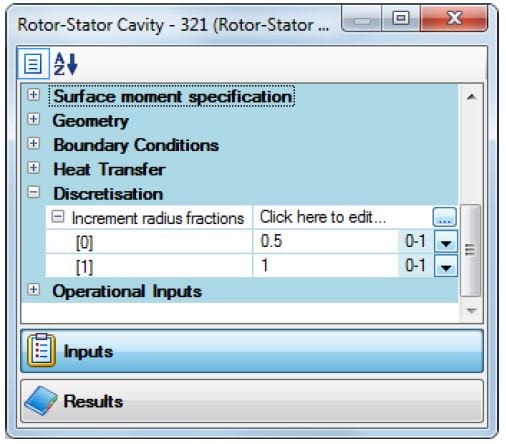

Subdivided Cavities

Another turbo machinery request was the ability to break cavities up into several radial zones, giving a more accurate pressure distribution in secondary flow applications for Rotor-Rotor and Rotor-Stator cavities. These subdivisions can be automatically created in the radial direction by Flownex.

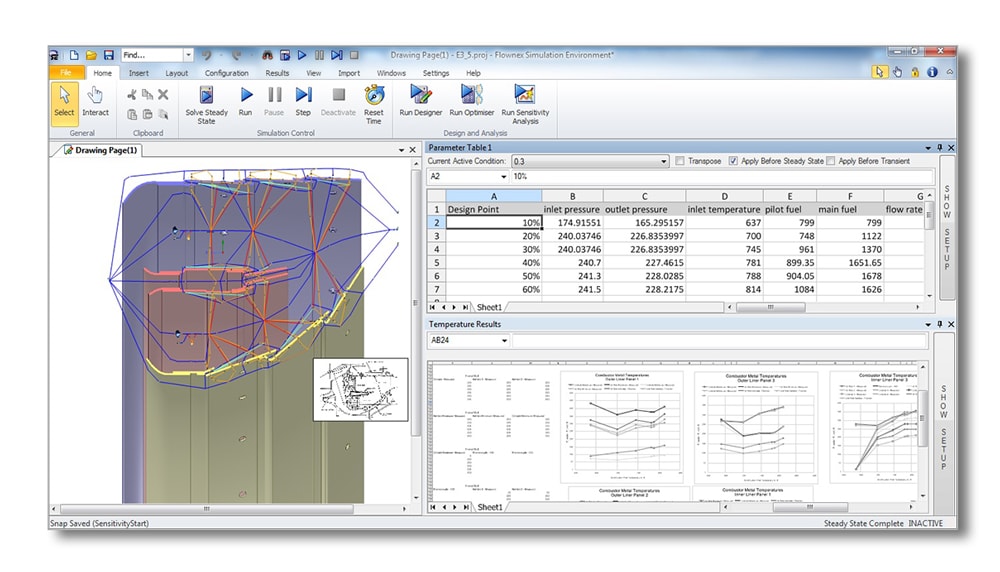

Excel Input Sheets and Parameter Tables

The connection between Microsoft Excel and Flownex has always been strong and useful, and it just get even better. So many people were connecting cells to their Flownex model parameters that the developers decided to directly connect the two programs so the user no longer has to establish data connection links. Now any properties in Flownex can be hooked to a cell in Excel.

The next thing users wanted was the ability to work with tables of parameters, so that was added as well. The user can hook a table of values in Excel to Flownex parameters and then have Flownex solve for the whole table, even returning resulting parameters. This makes parametric studies driven from Excel simple and powerful.

Component Enhancements

Users can now create component defaults and save them in a library. This saves time because in the past the user had to specify the parameters for a given component. Now thy just drag and job the existing defaults into their model.

Compound components have also been enhanced by the development team so you no longer have to restart Flownex when you move, export, or import a compound component.

Find Based on Property Values

Users can now search through properties on all the objects in their model based on the value assigned to those properties. As an example, you can type > 27.35 to get a list of all properties with an assigned value that is larger than 27.35. This saves time because the user no longer has to look through properties or remember what properties were assigned.

Network Creation through Programming

Users can now write programs through the API or scripting tool to build their network models. This will allow companies to create vertical applications or automate the creation of complex networks based on user input. Of all the enhancements in this update, this improvement has the potential to deliver the greatest productivity improvements.

Automatic Elevations Importing in GIS

Users who are specifying flow networks over real terrain can now pull elevation data from the internet, rather than requiring that the data be defined when the network is specified. This enhancement will greatly speed up the modeling of large fluid-thermal systems, especially when part of the simulation process is moving components of the system over terrain.

Multiple Fluid Interface Component

A very common requirement in fluid-thermal systems is the ability to model different fluids or fluid types and how they interact. With this update, users can now model two separate fluid networks and define a coupling between the two. The mass balance and resulting pressure at the interface is maintained.

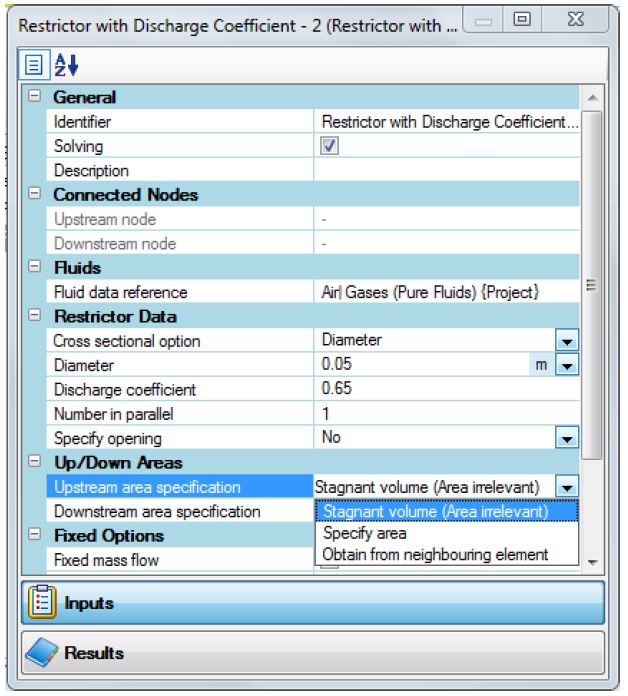

Static Condition Calculation Improvements

Many simulations require an accurate calculation of static pressures. To do this, the upstream and downstream areas and equivalent pipe diameters are needed to obtain the proper values. Many components now allow upstream and downstream areas to be defined, including restrictors and nozzles.

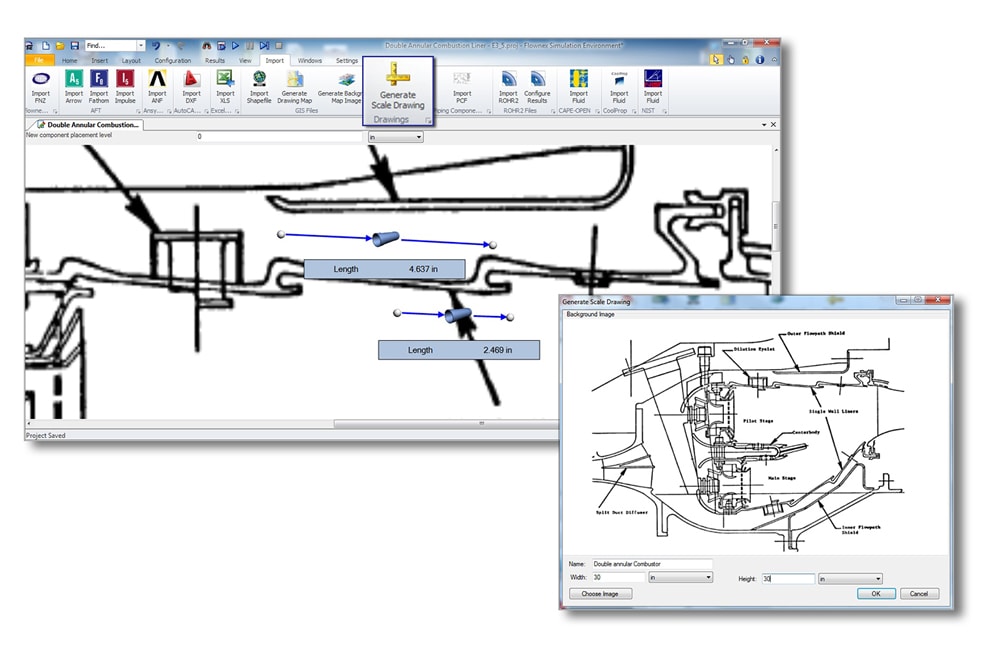

Scaled Drawing

The ability to create a scale 2-Dimensional drawing was added to Flownex. The user can easily add components onto an existing scaled drawing that is used as a background image in Flownex. These components will automatically detect and input lengths based on the drawing scale and distance between nodes. This results in much less time and effort spent setting up larger models where actual geometric sizes are important.

How do I Try this Out?

As you can see by the breadth and depth of enhancements, Flownex is a very capable tool that delivers on user needs. Written and maintained by a consulting company that uses the tool every day, it has that rare mix of detailed theory and practical application that most simulation engineers crave. If you model fluid-thermal systems, or feel you should be simulating your systems, contact Brian Duncan at 480.813.4884 or brain.duncan@padtinc.com. We can do a quick demo over the internet and learn more about what your simulation needs are. Even if you are using a different tool, you should look at Flownex, it is a great tool.