One of the first concepts you come across in metal 3D printing is the notion of reactivity of the powder metal alloys – in this post, I investigate why some of these powder alloys are classified as reactive and others as non-reactive, and briefly touch upon the implications of this to the user of metal 3D printing tools, scoping the discussion to laser-based powder bed fusion. Ultimately, this boils down to a safety issue and I believe it is important that we, the users of these technologies, truly understand the fundamentals behind the measures we are trained to follow.

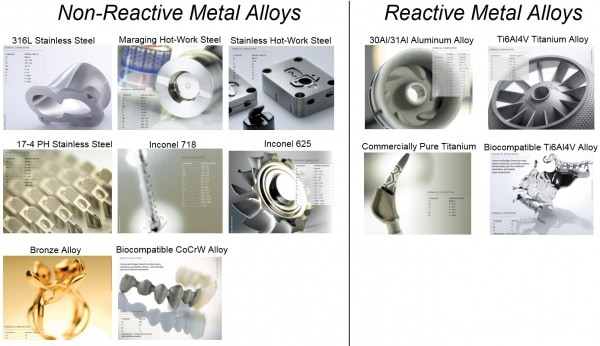

Figure 1 below is indicative of the range of materials available currently for the laser-based powder bed fusion process (this selection is from Concept Laser). I have separated these into non-reactive and reactive metal alloys. The former includes steels, Inconels, bronze and CoCrW alloys. The reactive metal alloys on the other hand are Aluminum or Titanium based. The question is: what classifies them as such in the context of this process?

Reactivity in this process really pertains to the likelihood of the alloy in question serving as a fuel for a fire and/or an explosion, which are two related but distinct phenomena. To truly understand the risk associated with powder metals, we must first understand a few basic concepts.

1. Fire and Explosion Criteria

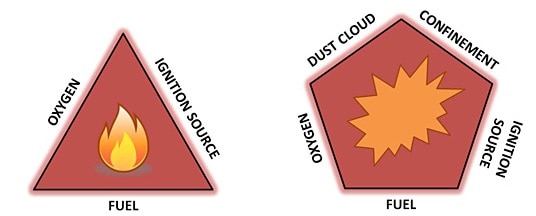

Figure 2 is a commonly used representation of the criteria that need to be met to initiate a fire (fuel, oxygen and an ignition source) and an explosion (the same three criteria for a fire, plus a dust cloud and confined space). When handling reactive metal alloy powders, it is important to remember that two of the three requirements for a fire are almost always met and the key lies in avoiding the other criterion. When not processing the powder in the machine, it is often subject to ambient oxygen content and thus all precautions are taken to prevent an ignition source (an ESD spark, for example). When the metal is being processed with a high power laser, it is done in an inert atmosphere at very low Oxygen levels. This thought process of appreciating you are one criterion away from a fire is useful, if sobering, to bear in mind when working with these powders. Well in case of fire explosion which can harm that should be resist or plan to resist.

2. Terms Used to Describe Fire and Explosion Risk

There are several terms used to describe fire and explosion risk. I have picked 5 here that tie into the overall “index” I will discuss in the following section. All these parameters are in turn functions of the material in question, both with regard to its composition and its size distribution and are co-dependent. These definitions are adapted from Benson (2012) and Prodan et al. (2012).

- Fire Related: These two terms describe the sensitivity of a metal dust cloud to ignition.

- Ignition Temperature: This is the lowest surface temperature capable of igniting a powder or dust dispersed in the form of a dust cloud

- Minimum Ignition Energy: This measures the ease of ignition of a dust cloud by electrical and electrostatic discharges.

- Explosion Related: These terms describe the severity of an explosion arising from a fire once ignited.

- Minimum Explosion Concentration (MEC): This is the smallest amount of dust which when suspended in air, under a set of test conditions, will initiate an explosion and propagate even after the action of the ignition source has ceased.

- Maximum Explosion Pressure: This is a measure of the highest pressure that occurs during of an explosion of a flammable mixture in a closed vessel.

- Maximum Rate of Pressure Rise: This is the maximum slope of the pressure/time curve during a flammable mixture explosion in a closed vessel.

3. Index of Explosibility

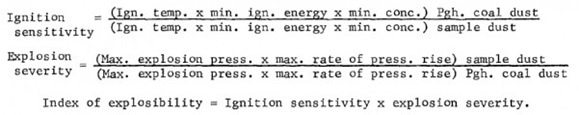

Having defined these terms, the question is how they can be tied together to give some sense of the hazard associated with each metal powder. I came across a 1964 US Bureau of Mines study that defined an Index of Explosibility as a measure of the hazard risk posed by powder metal alloys. The index represents both the sensitivity of the powder to ignition, and once ignited, the severity of the resulting explosion. Since this is a subjective metric, it is normalized by comparison against a “standard”, which was selected as Pittsburgh coal dust in the 1964 study. Importantly though, this normalization enables us to do qualitative comparisons between metal powders and have some sense of the hazard risk posed by them. Figure 3 is the equation reproduced from the original 1964 report and shows how this term is estimated.

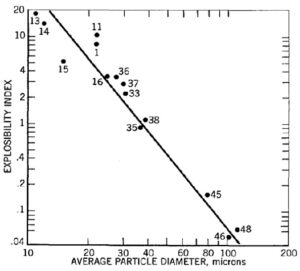

The study also showed how the index was a direct function of particle size. Most powders for 3D metal printing are in the 20-100um range, and as shown in Fig. 4 for atomized Aluminum, the risk of an explosion increases with reducing particle diameter.

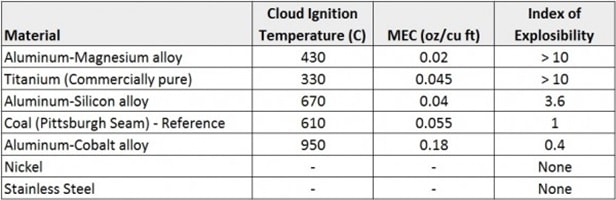

The authors tested a range of metals and computed the different variables, which I have compiled anew in the table in Figure 5 for the ones we are interested in for metal 3D printing. The particle sizes in the 1964 study were ones that made it through a No. 200 sieve (less than 75 microns), but did not include sub-micron particles – this makes it an appropriate comparison for metal 3D printing. It is clear from the Index of Explosibility values, as well as the Cloud Ignition Temperatures in the table below why Aluminum and Titanium are classified as reactive metals requiring special attention and care.

4. Implications for Metal 3D Printing

So what does this mean for metal 3D printing? There are three things to be aware of that are influenced by whether you are working with non-reactive or reactive alloys – I only provide a general discussion here, specific instructions will be provided to you in supplier training and manuals and must be followed.

- Personal Protective Equipment (PPE): There are typically two levels of PPE: standard and extended. The standard PPE can be used for non-reactive alloy handling, but the reactive alloys require the more stringent, extended PPE. The main difference is that the extended PPE requires the use of a full bunny suit, ESD grounding straps and thermal gloves.

- Need for Inert Gas Handling: Many tasks on a metal 3D printer require handling of powder (pouring the powder into the chamber, excavating a part, cleaning the chamber of powder etc.). Most of these tasks can be performed in the ambient for non-reactive metal alloys with standard PPE, but for reactive alloys these tasks must be performed in an inert atmosphere.

- Local authority approvals: It is important that your local authorities including the fire marshall, are aware of the materials you are processing and review and authorize their use in your facility before you turn on the machine. Local regulations may require special procedures be implemented for preparing the room for use of reactive metal alloys, that do not apply to non-reactive metals. It is vital that the authorities are brought into the discussion early on and necessary certifications obtained, keeping in mind that reactive metal alloy use may drive additional investment in safety measures.

5. Conclusion

Safe operation of metal 3D printers requires installation of all the necessary safety equipment, extensive hands-on training and the use of checklists as memory aides. In addition to that, it helps to connect these to the fundamental reasons why these steps are important so as to gain a clearer appreciation of the source of the hazard and the nature of the risk it poses. In this article I have tried to demonstrate why reactivity in metal 3D printing matters and what the basis is for the classification of these metal alloys into reactive and non-reactive by leveraging an old 1964 study. I wish to close with a reminder that this information is meant to supplement formal training from your equipment supplier – if there is any conflict in the information presented here, please revert to your supplier’s recommendations.

Thank you for reading; stay safe as you innovate!