To highlight this power and capability, PADT and Flownex will be exhibiting at the 2016 SMR conference in Atlanta where we will be available to discuss exciting new Flownex developments in system and subsystem simulations of SMRs. If you are attending this year’s event, please stop by the Flownex booth and say hello to experts from M-Tech and PADT.

If you are not able to make the conference or if you want to know more now, you can view more information from the new Flownex SMR brochure or this video:

Why is Flownex a Great Tool for SMR Design and Simulation?

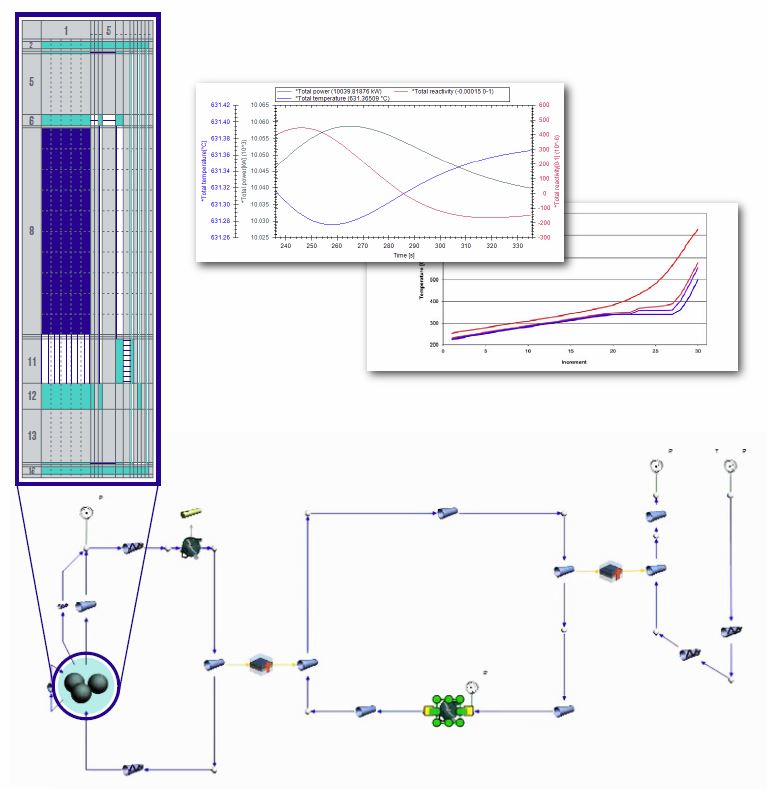

These developments offer greatly reduced times for performing typical design tasks required for Small Modular Nuclear Reactor (SMR) projects including sizing of major components, calculating overall plant efficiency, and design for controllability

This task involves typical components like the reactor primary loop, intermediate loops, heat exchangers or steam generators and the power generation cycle. Flownex provides for various reactor fuel geometries, various reactor coolant types and various types of power cycles.

Flownex can also be used for determining plant control philosophy. By using a plant simulation model, users can determine the transient response of sensed parameters to changes in input parameters and based on that, set up appropriate pairings for control loops.

For passive safety system design Flownex can be used to optimize the natural circulation loops. The program can calculate the dynamic plant-wide temperatures and pressures in response to various accident scenarios, taking into account decay heat generation, multiple natural circulation loops, transient energy storage and rejection to ambient conditions.

Learn more at www.padtinc.com/flownex, give us a call at 480.813.4884 or email brian.duncan@padtinc.com.