A copy of the press release is below. Or read the official press release or download a PDF .

Press Release:

Innovative Additive Manufacturing Research Project Led by PADT Approved as Part of America Makes Multi-Million Dollar Grants

Arizona State University, Honeywell Aerospace and LAI International join PADT in technical research and educational outreach in 3D Printing

TEMPE, Ariz., July 25, 2016 — In one of the most critically needed areas of research in Additive Manufacturing, Phoenix Analysis & Design Technologies (PADT), the Southwest’s largest provider of numerical simulation, product development and 3D Printing services and products, today announced its project proposal titled “A Non-Empirical Predictive Model for Additively Manufactured Lattice Structures,” has been accepted as part of a multi-million dollar grant from the National Additive Manufacturing Innovation Institute, America Makes. PADT’s proposal was one of only seven selected, and one of only two where the leading organization was a small business.

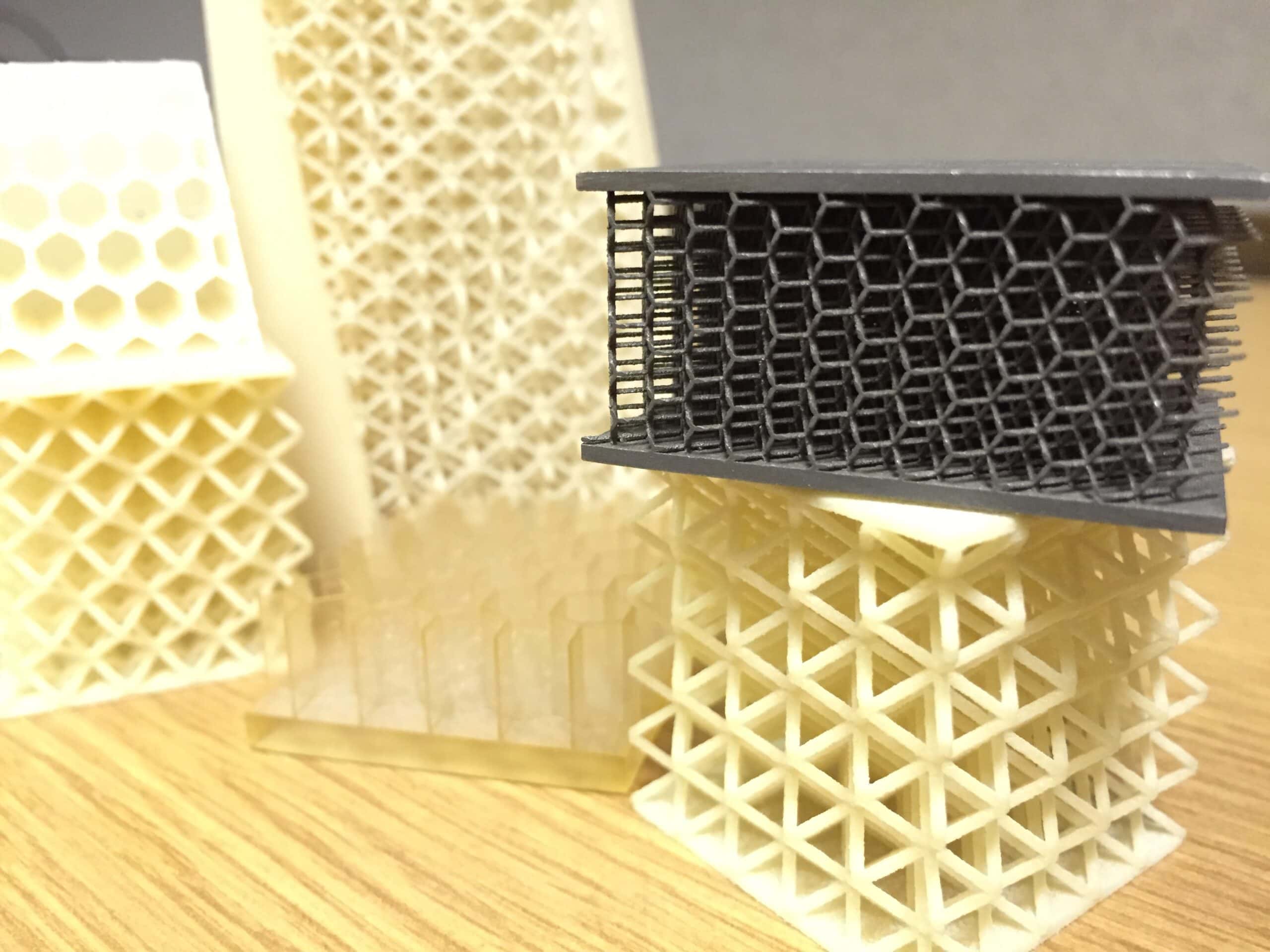

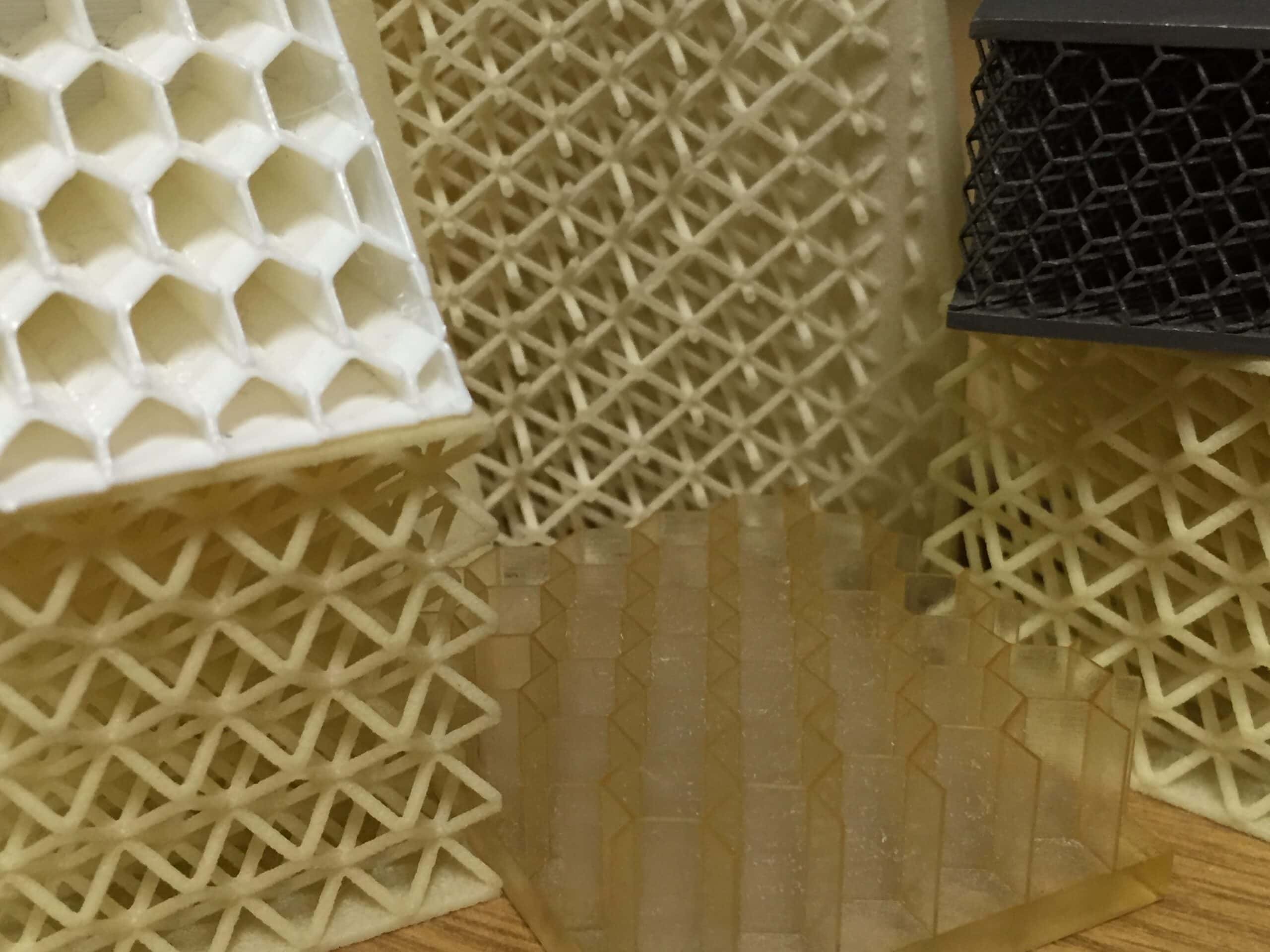

“While there are several efforts ongoing in developing design and optimization software for lattice structures in additive manufacturing, there has been little progress in developing a robust, validated material model that accurately describes how these structures behave,” said Dhruv Bhate, PhD, senior technologist, PADT and author and principal investigator of the proposal. “We are honored to be chosen to research this important issue and provide the tools to enable entrepreneurs, manufacturers and makers to integrate lattice structures in their designs.”

One of the most definitive benefits of additive manufacturing is the ability to reduce weight while maintaining mechanical performance. A way to achieve this is by adding lattice structures to parts before manufacturing. The advantages are crucial and can result in increased design flexibility, lower material costs and significant reductions in production time for industries such as aerospace and automotive.

Another aspect of PADT’s winning proposal is the development of a first-of-a-kind online, collaborative living textbook on Additive Manufacturing that seeks to provide comprehensive, up-to-date and structured information in a field where over 50 papers are published worldwide every day. In addition, the team will develop a training class that addresses manufacturing, testing, theory and simulation as well as how they are combined together to deliver robust predictions of lattice behavior.

“We have identified Additive Manufacturing as a key lever of innovation in our company and recognize lattice structures as an important design capability to reduce mass, improve performance and reduce costs,” said Suraj Rawal, Technical Fellow, Advanced Technology Center at Lockheed Martin Space Systems Company – a leader in implementing Additive Manufacturing. “We also recognize the significance of this work in lattice behavior modeling and prediction as an important contribution to help implement the design, manufacturing, and performance validation of structures in our innovative designs.”

The award of this grant is another example of the leadership role that Arizona is playing in advancing the practical application of Additive Manufacturing, better known as 3D Printing. PADT’s leadership role in the Arizona Technology Council’s Arizona Additive Manufacturing Committee, support of basic research in the area at ASU, and involvement with educating the next generation of users underscores PADT’s contribution to this effort and furthers the company’s commitment to “Make Innovation Work.”

About Phoenix Analysis and Design Technologies

Phoenix Analysis and Design Technologies, Inc. (PADT) is an engineering product and services company that focuses on helping customers who develop physical products by providing Numerical Simulation, Product Development, and Rapid Prototyping solutions. PADT’s worldwide reputation for technical excellence and experienced staff is based on its proven record of building long term win-win partnerships with vendors and customers. Since its establishment in 1994, companies have relied on PADT because “We Make Innovation Work.” With over 80 employees, PADT services customers from its headquarters at the Arizona State University Research Park in Tempe, Arizona, and from offices in Torrance, California, Littleton, Colorado, Albuquerque, New Mexico, and Murray, Utah, as well as through staff members located around the country. More information on PADT can be found at http://www.PADTINC.com.

| Media Contact Linda Capcara TechTHiNQ on behalf of PADT 480-229-7090 linda.capcara@techthinq.com |

PADT Contact Dhurv Bhate, PhD Senior Technologist, PADT 480.813.4884 dhruv.bhate@padtinc.com |