Is PolyJet MED610 truly biocompatible? And what does that mean anyway?

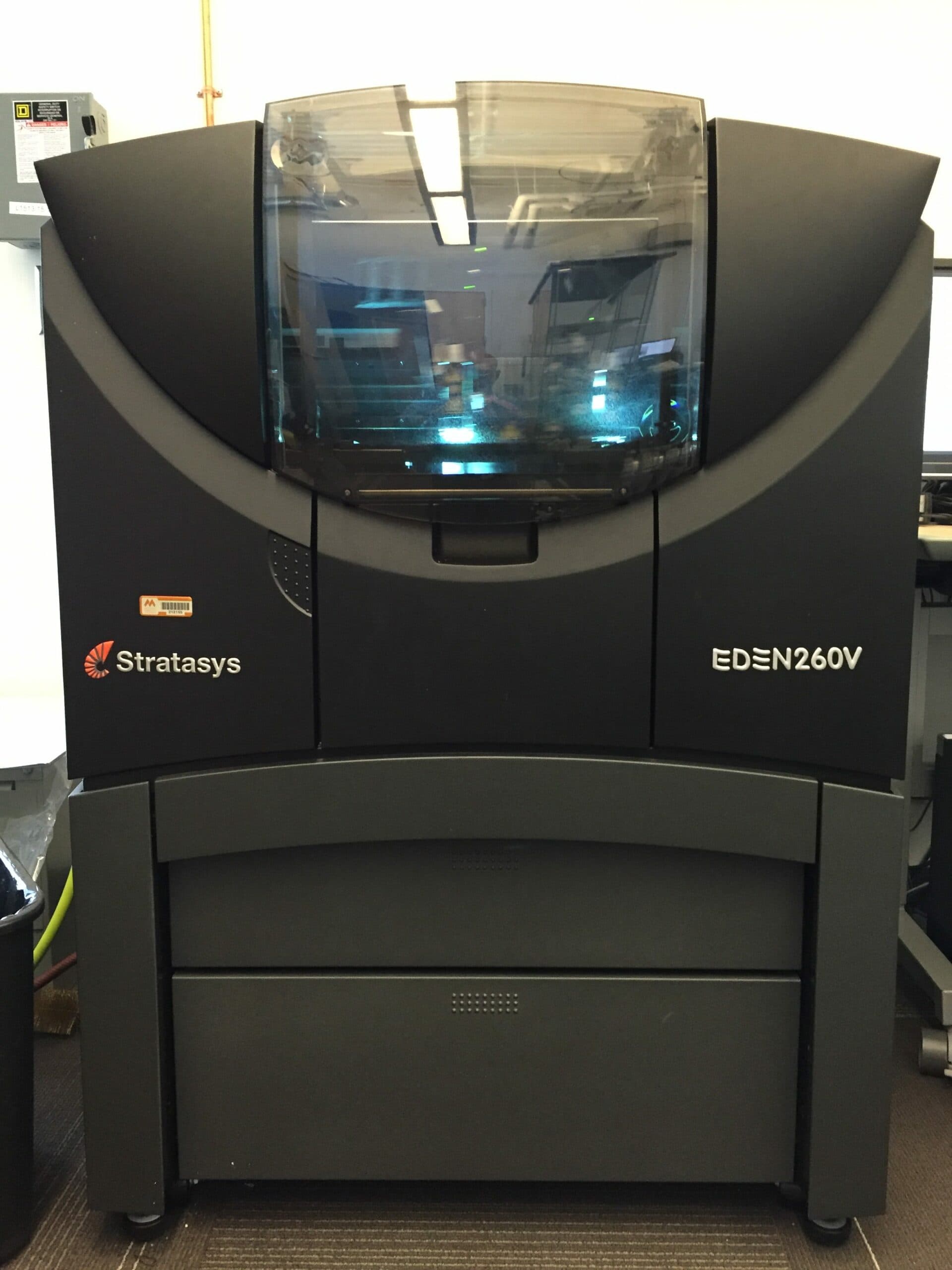

A couple of months ago, our product development team contacted me to see if I could 3D print them a small bio-compatible masking device that was needed for temporary attachment to an invasive device prior to insertion for surgery. That led me to investigate all the different bio-compatible materials we did have access to at PADT on our FDM (Fused Deposition Modeling) and PolyJet machines. Given the tiny size and high detail required in the part, I decided to opt for PolyJet, which does offer the MED610 material that is claimed to be biocompatible. As it so happens, we have an Objet Eden 260V PolyJet machine that has been dedicated to running MED610 exclusively since it’s installation a year ago.

We printed the mask, followed all the post-processing instructions per supplier recommendations (more on that later) and delivered the parts for further testing. And that is when I asked myself the questions at the top of this post.

I set off on a quest to see what I could find. My first stop was the RAPID conference in (May 2016), where the supplier (Stratasys Inc.) had a well-staffed booth – but no one there knew much about MED610 apart from the fact that some orthodontists were using it. I did pick up one interesting insight: one of the engineers there hypothesized that MED610 was not very popular because it was cost-prohibitive since its proper use required machine dedication. I then went to the Stratasys Direct Manufacturing (a service bureau owned by Stratasys) booth, but it turned out they don’t even offer MED610 as a material option for service jobs – presumably because of the low demand for this material, consistent with our own observations.

So I took a step back and began searching for all I could find in the public domain on MED610 – and while it wasn’t much, here is the summary of my findings that I hope help anyone interested in this. I categorize it in three sources of information: claims made by the supplier, published work on in vitro studies and finally, some in vivo animal trials. But first, we must ask…

What does it mean for a Material to be Biocompatible?

A definition by Williams (The Williams Dictionary of Biomaterials, 1999) is in order: “Biocompatibility is the ability of a material to perform with an appropriate host response in a specific application.” So if PolyJet MED610 is to be called biocompatible, we must ask – what application do we have in mind? Fortunately, the supplier has a recommendation.

Supplier Claims

MED610 was launched by Objet in 2011 (Objet was acquired by Stratasys in 2012) as a biocompatible material, ideal for “applications requiring prolonged skin contact of more than 30 days and short-term mucosal-membrane contact of up to 24 hours“. Stratasys claims that parts printed according to Objet MED610 Use and Maintenance Terms were evaluated for biocompatibility in accordance with standard “DIN EN ISO 10993-1: 2009, Biological Evaluation of Medical Devices-Part 1: Evaluation and testing within a risk management process. This addresses cytotoxicity, genotoxicity, delayed hypersensitivity, and USP plastic Class VI, which includes the test for irritation, acute systemic toxicity and implantation”. Unfortunately, the actual data from the biocompatibility study conducted by Objet have not been made publicly available.

It is important to remember that Stratasys publishes a “Use and Maintenance Terms” document that details the steps needed not just to clean the part after printing, but also on the proper setup of the machine for ensuring best chances of meeting biocompatibility requirements. These are published online at this link and include a 3 hour soak in a 1-percent NaOH solution, a 30 min soak in IPA and multiple water jet rinses, among other steps. In other words, the claimed biocompatibility of MED610 is only valid if these instructions are followed. These steps are primarily driven by the need to completely remove supports and any support-residue, but it is not clear if this is needed if a part can be printed without supports. Given such strong process dependencies, it is only to be expected that Stratasys provide a disclaimer at the end of the document clarifying that the users of their machines are responsible for independently validating biocompatibility of any device they make with MED610.

The next question is: have there been any relevant published, independent studies that have used MED610? In my search, I could only find two instances, which I discuss below.

Primary Human Cells Response (In Vitro)

In a recent (January 2016) study published in the Journal of Medical and Biological Engineering, Schmelzer et al. studied the response of primary human cells to four 3D printed materials in vitro: ABS, PC, PLA and MED610 – the only such study I could find. All samples instead went through a 100% ethanol brief rinse and were washed 5 times with de-mineralized water – this seems like a less stringent process than what the supplier recommends (3 hour 1-percent NaOH solution soak, 30 minutes IPA soak and 10 times waterjet blasting) but was designed to be identical across all the materials tested.

There were some very interesting findings:

- Different cells had different responses:

- MED610 had the most negative impact on cell viability for keratinocytes (epidermal cells that produce keratin) – and the only material that showed statistically significant difference from the control.

- For bone marrow mesenchymal (stem) cells, a different effect was observed: direct culture on ABS and PC showed significant growth (7X compared to control) but MED610 and PLA showed no significant effect

- Surface Roughness influences cell attachment and proliferation:

- In agreement with other work, the authors showed that while rougher surfaces promote initial cell attachment, subsequent cell proliferation and overall cell numbers are higher on smoother surfaces. The MED610 samples had rougher surfaces than the FDM samples (possibly due to the use of the “matte” finish option) and could be one of the contributors to the observed negative effects on cell viability, along with the leached contents from the specimen.

Glaucoma Drainage Device (In Vivo, Rabbit studies)

A group of Australian researchers published a 2015 paper where they designed and used PolyJet MED610 to manufacture a Glaucoma Drainage Device (GDD). They selected PolyJet because of its ability to resolve very fine details that they needed for the device. Importantly, the purpose of this study was to assess the effect of different design parameters on the effectiveness of the device (relieving intraocular pressure). The device was implanted into rabbit eyeballs where it remained for up to 4 weeks.

The devices were printed on a Connex 350 PolyJet machine, after which the supports were removed from the devices with a water jet and “were repeatedly washed and inspected for consistency and integrity.” Tubes were attached with Silicone adhesive and the entire assembly was then “washed and sterilized with a hospital-grade hydrogen peroxide system before use”. The researchers did not examine the cellular and extracellular reactions in great detail, but did conclude that the reactions were similar between the MED610 device and the more standard polypropylene injection-molded device.

A short video recorded by some of the researchers as part of a Bioprinting course also provides some details into the 3D printing aspects of the work done.

Concluding Thoughts

In conclusion, the question I posed at the start of this post (Is PolyJet MED610 truly biocompatible?) is too simplistic. A process and a material together are not sufficient – there are procedures that need to be defined and controlled and further and more importantly, biocompatibility itself has to be viewed in the context of the application and the specific toxicity and interaction demands of that application. And that brings us to our key takeaways:

- MED610 is only recommended at best for applications requiring prolonged skin contact of more than 30 days and short-term mucosal-membrane contact of up to 24 hours and there is no data to dispute the suppliers claim that it is biocompatible in this context once all recommended procedures are implemented

- The work done by Australian researchers in using PolyJet MED610 for devoloping their Glaucoma Drainage Device in animal trials is perhaps the best example of how this material and the technology can be pushed further for evaluating designs and hypothesis in vivo when really fine features are needed. Stratasys’s FDM PC-ISO or ABS M30i materials, or other FDM extrusion capable materials like PLA, PCL and PLGA may be better options when the resolution allows – but this is a topic for a follow-on blog post.

- More in vitro work needs to be done to extend the work done by Schmelzer et al., which suggests that MED610 potentially has leachables that do impact cell viability negatively. Specifically, effects of surface finish (“matte” vs “gloss”) and sterilization on cell viability is a worthwhile follow-on step. In the interim, MED610 is expected to perform well for mucosal membrane contact under 24 hours (and why this is a great technology for dental guides and other temporary in-mouth placement).

If you have any thoughts on this matter or would like to collaborate with us and take advantage of our access to a PolyJet printer that is dedicated to MED610 or other bio-compatible FDM materials, as well as our extensive post-processing and design & analysis facilities, please connect with me on LinkedIn or send us a note at info@padtinc.com and cite this blog post.

Thanks for reading!

References

- Stratasys Bio-compatible Materials Page: http://www.stratasys.com/materials/polyjet/bio-compatible

- PolyJet MED610 Data Sheets: http://www.stratasys.com/materials/material-safety-data-sheets/polyjet/dental-and-bio-compatible-materials

- Schmelzer, E., Over, P., Gridelli, B., & Gerlach, J. (2016). Response of Primary Human Bone Marrow Mesenchymal Stromal Cells and Dermal Keratinocytes to Thermal Printer Materials In Vitro. Journal of Medical and Biological Engineering, 36, 153-167.

- Ross C, Pandav S, Li Y, et al. Determination of Bleb Capsule Porosity With an Experimental Glaucoma Drainage Device and Measurement System. JAMA Ophthalmol.2015;133(5):549-554. doi:10.1001/jamaophthalmol.2015.30.

- Glaucoma case study in online course on Bioprinting, University of Woolongong, Future Learn, https://www.futurelearn.com/courses/bioprinting/3/steps/87168