I had a really great time designing the Metal 3D printed shift knob from my previous blog post. I was curious what the other benefits of the knob may be besides being cool to look at and show off. What better way than to use the simulation software that we use here at PADT every day!

One of the clear differences between my solid spherical knob and the Metal 3D printed version is surface area. Being that PADT is based in Tempe, AZ, some may say that we have “warm” summers down here. Couple the 120F days with a black car, and the interior can get very hot, at some points feeling like the sun itself has taken up residence inside the back seat. With modern A/C, this heat can be mitigated fairly quickly, only to attempt to shift into gear to be scalded by the shift knob!

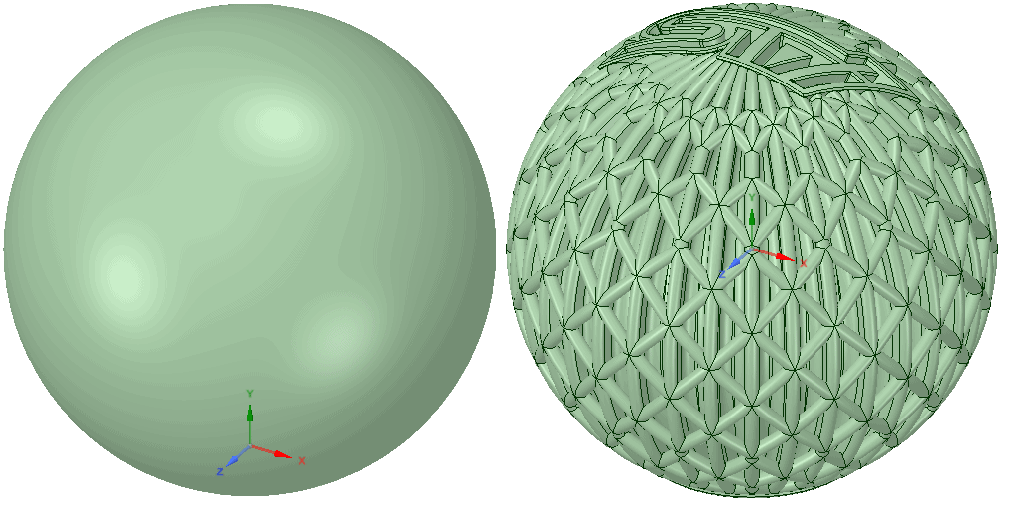

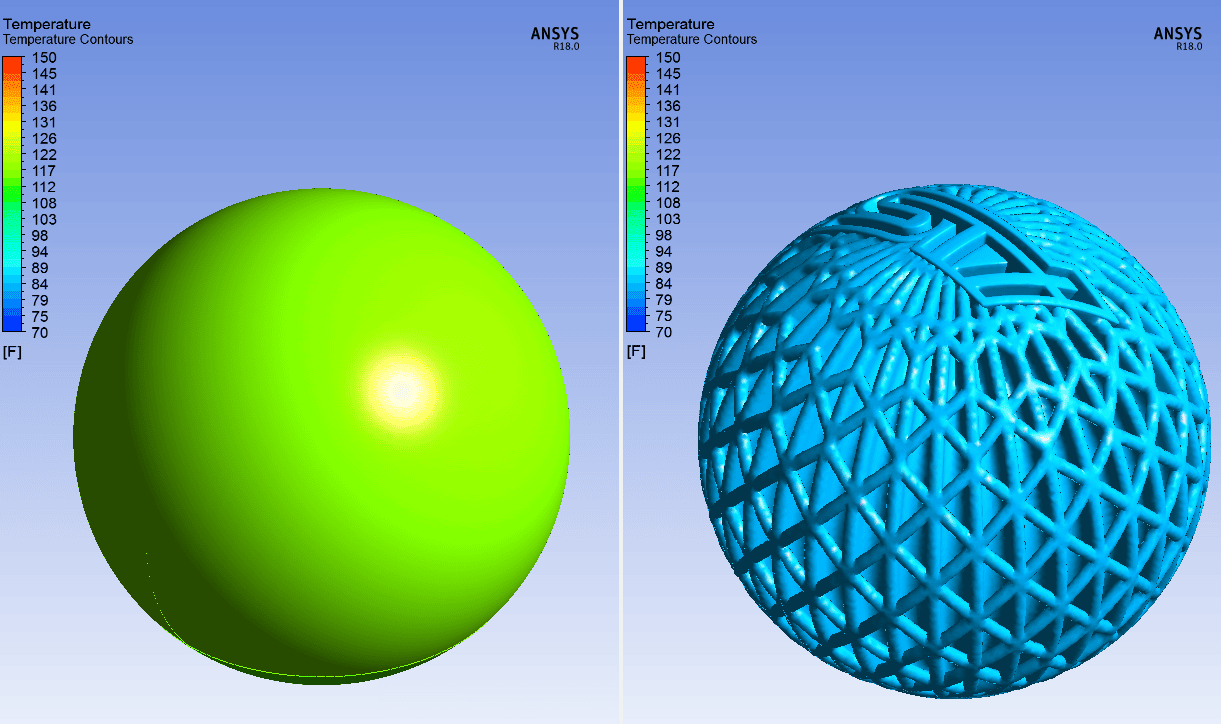

I wanted to see what the rate of cooling for the two knobs would be in a basic situation with some basic assumptions. Using ANSYS transient thermal, I initialized the knobs to 150F, temperatures that can be quickly reached in parked cars here in AZ. I added a convection heat transfer boundary condition on the outer surface of each shift knob, assuming a film coefficient of 50 W/m^2C, and that the ambient temp in the car is at a cool 70F.

I ran the simulations for 5 minutes, and the results were in line with what I expected. As the 3D printed knob has more surface area for cooling, it’s final temperature was ~84F, compared to the solid spherical knob at a final temperature of 115F!

Want to learn more, check out the article in “Additive Manufacturing Media.”