It was such a great story that two publications were interested and wrote far better writeups than I could.

The first is interesting because it is an industry trade magazine for people in the floor installation business. Their perspective is refreshing for those of us who live in the engineering world, getting more into the practical application of the product:

http://digital.bnpmedia.com/publication/?i=422744#{“issue_id”:422744,”page”:52}

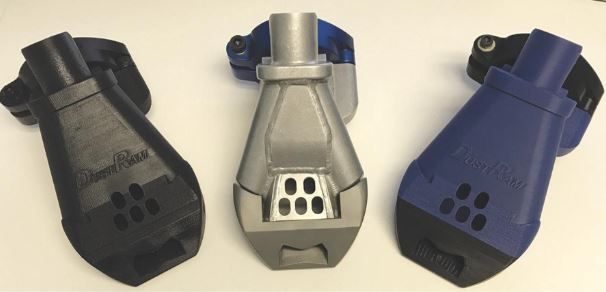

This was preceded by a fantastic article in Additive Manufacturing magazine that gets more into the technical side:

If you want to learn more about how you can use additive manufacturing to produce yout production hardware, contact us today.