Part of the PADT core Philosophy is to “Provide flexible solutions of higher quality in less time for less money”. This part of the philosophy also applies to how we design and build PADT’s internal structure, tools we use, and processes we adopt.

Among the growing pains of most engineering and simulation organizations is the constant growing demand for storage capacity, data management, and protection, and BOATLOADS of computing power. Sadly, PADT engineers have yet to develop a near infinite storage capacity (like DNA for storage) or a working quantum computer that can run ANSYS. So we’re in the same boat with everyone else. We have been exploring what are our major pains and what optimizations can be made to our simulation environment (about 2,000 cores of Cube Simulation Cluster Appliances) as well as a structured, controlled solution for engineering data management.

As always we started by looking inwards:

- What skills are available, or learnable within PADT that can help address the need?

- What tools & resources do we have access to?

- What do we need to acquire or buy?

The immediate and most obvious answer was to utilize PADT’s internal pool of knowledge and an ANSYS product called Engineering Knowledge Manager (EKM for short).

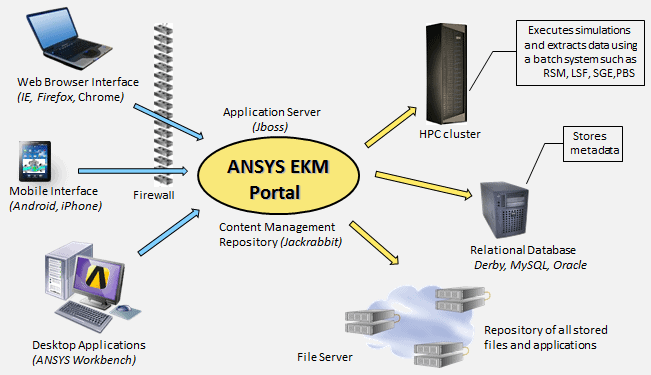

ANSYS EKM is a tool purposely developed to provide a turnkey solution for simulation process and simulation data management. This means that users can – through a single interface – perform a full simulation lifecycle. In the next few paragraphs, I will briefly go over some of the main features of ANSYS EKM with a couple of screenshots for good measure.

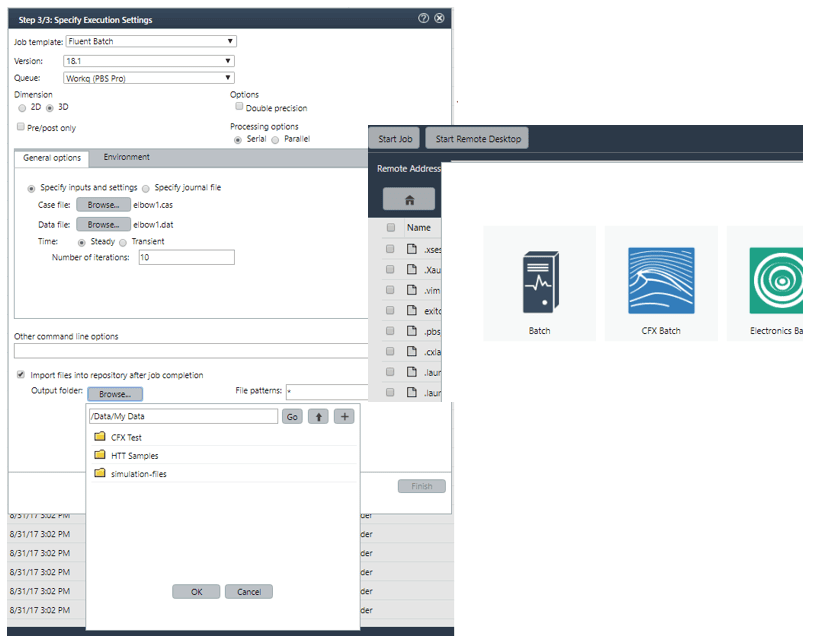

Interactive and batch submission to high-performance computing resources

For PADT, a very practical feature of EKM is the ability to easily interface to existing High-Performance Computing (HPC) infrastructure. By communicating through ANSYS Remote Solve Manager (RSM), EKM is able to effortlessly interface to most HPC schedulers and resource managers for both the Windows and Linux worlds.

This feature is huge because analysts can seamlessly upload their models into the secure EKM repository, submit the jobs to the HPC cluster/s, monitor their runs, and upload their choice of results directly into EKM for review and post-processing.

EKM works hard to keep the interface familiar to flatten the learning curve and keep things simple by making the batch submission menus as close as possible to the local ones.

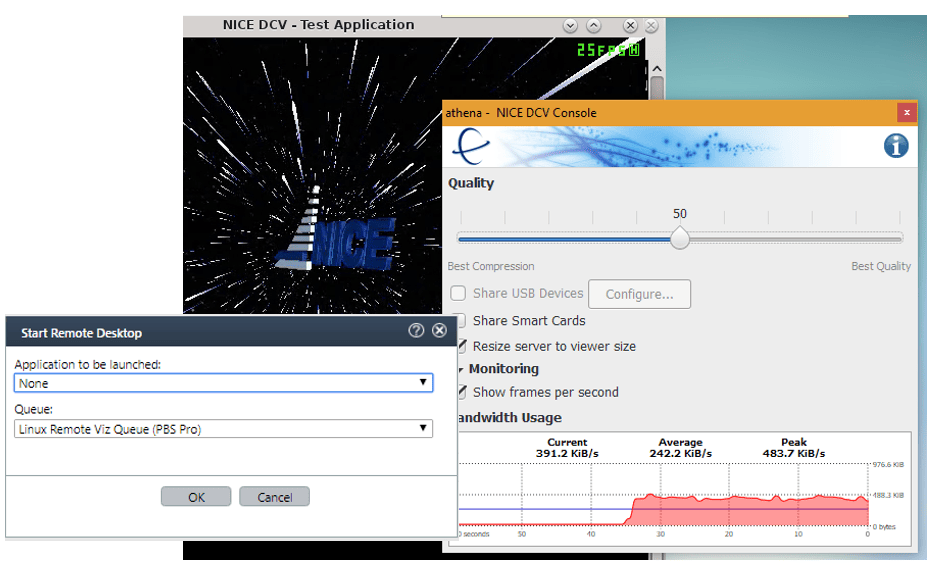

At PADT, whenever we are debugging models or application behavior, we want to have an interactive session to have the most control and visibility of the environment. With EKM, we can utilize the remote visualization & acceleration tool Nice – DCV. DCV is launched from within EKM and provides access to an interactive desktop on a cluster target while also accelerating OpenGL graphics for visually intensive programs.

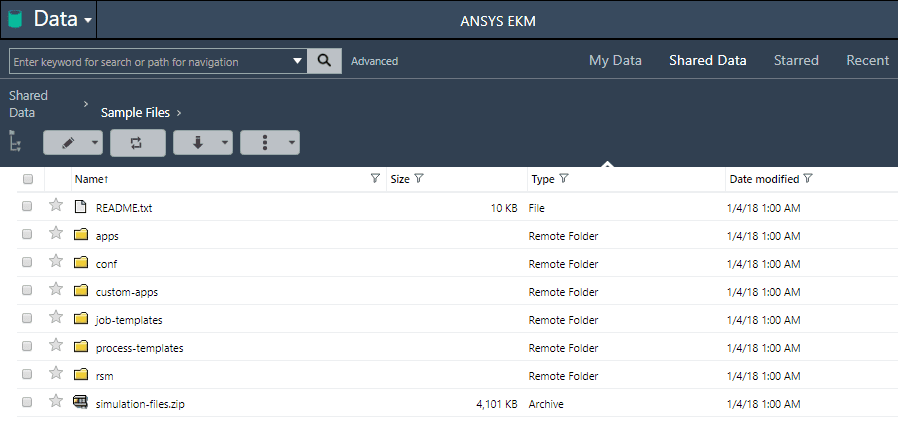

Storage and archiving of simulation data with built-in version control, data aging, and expiry.

ANSYS EKM provides a comprehensive data management toolset that is derived from real-world needs. Features like highly granular access control, file and folder sharing and collaboration, version control, check-out and check-in procedures, and many more are enabled and very powerful out of the box. Other more advanced features such as data aging, auto-archiving, auto unpacking option for zip files are also very useful.

The capabilities don’t end here as EKM integrates directly with ANSYS Workbench. Analysts can seamlessly access their EKM repository from Workbench to perform any modifications and directly save back to EKM without the need to switch applications. Check-outs are automatically checked back in and new version numbers can be created automatically as well.

Metadata extraction

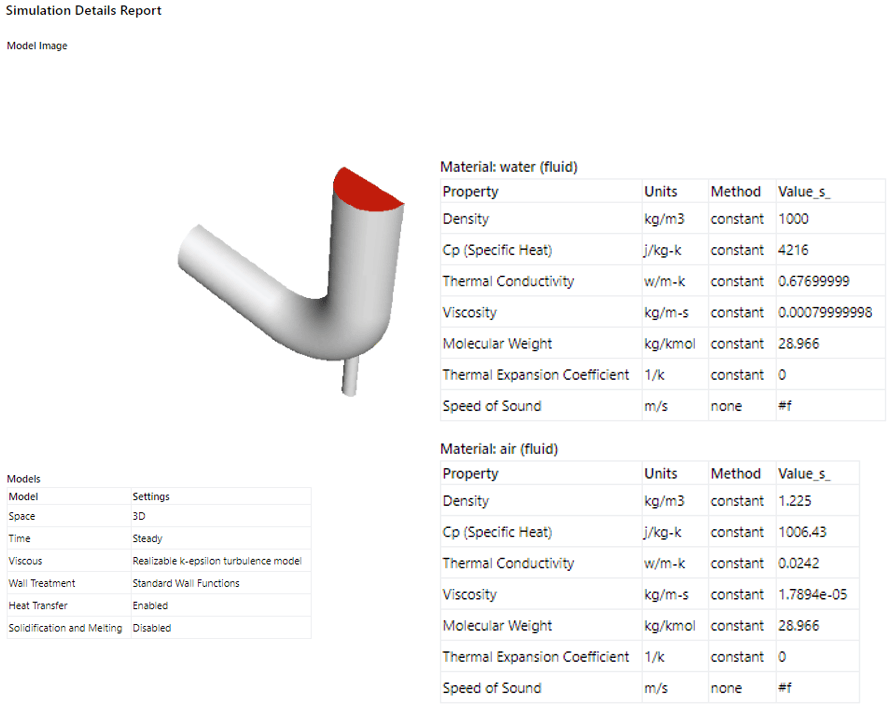

An extremely powerful piece of EKM is the metadata extraction engine that is baked into the core. EKM stores files as two entries, original file, and file metadata. EKM goes beyond the basic filename, date, owner metadata and digs deeper. It digs into the CAE meaningful metadata of the model, setup, material properties, element counts, mesh type and so on. It also extracts snapshots of the geometry, contours and in some cases even provides a 3d model that can be directly manipulated by the user. A sample of an ANSYS Fluent case metadata is below.

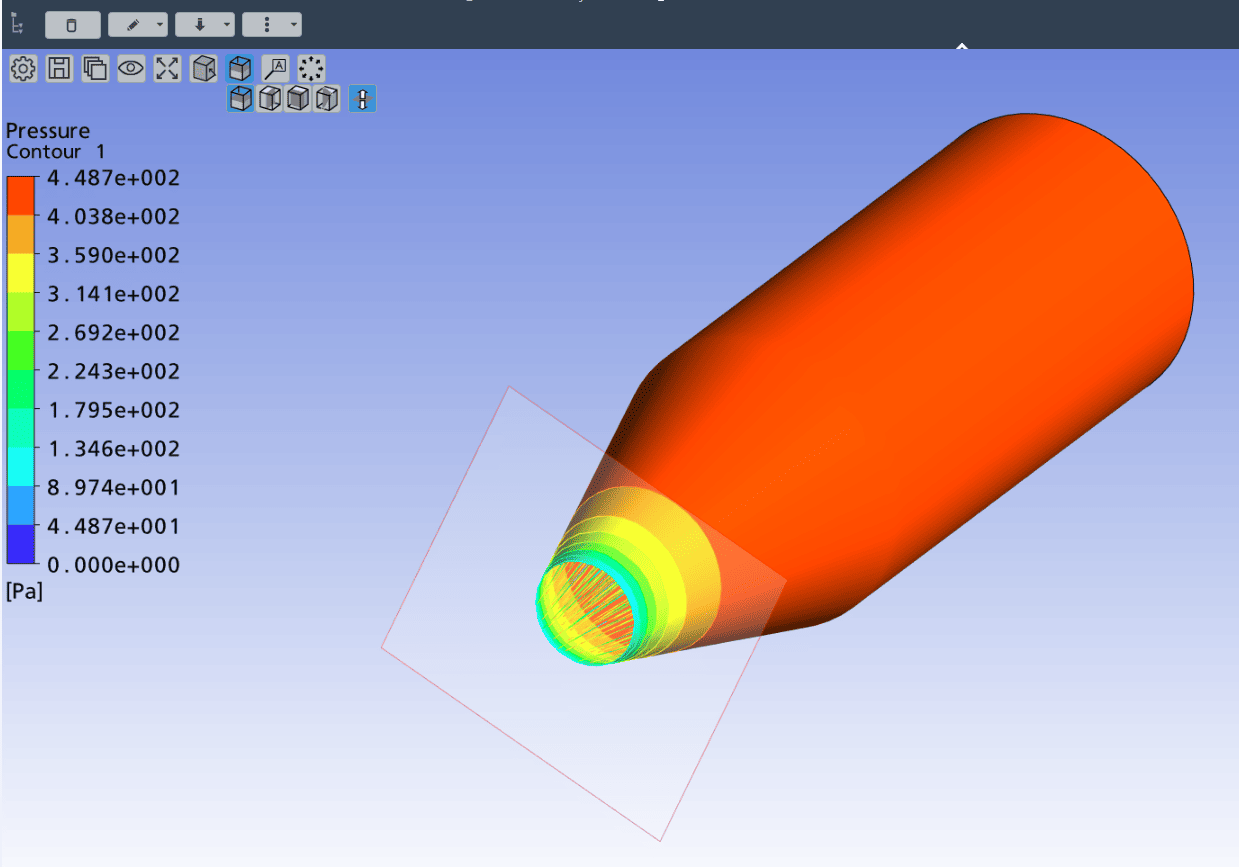

Another feature of metadata extraction is the ability to take a quick look at simulation results, perform cutplanes, pan, tilt, and zoom as well as add comments and even capture and share snapshots without leaving the browser window.

Metadata extraction is supported for ANSYS data types and the ability to define new data types is straightforward and easy to do for any other CAE data types or in-house codes.

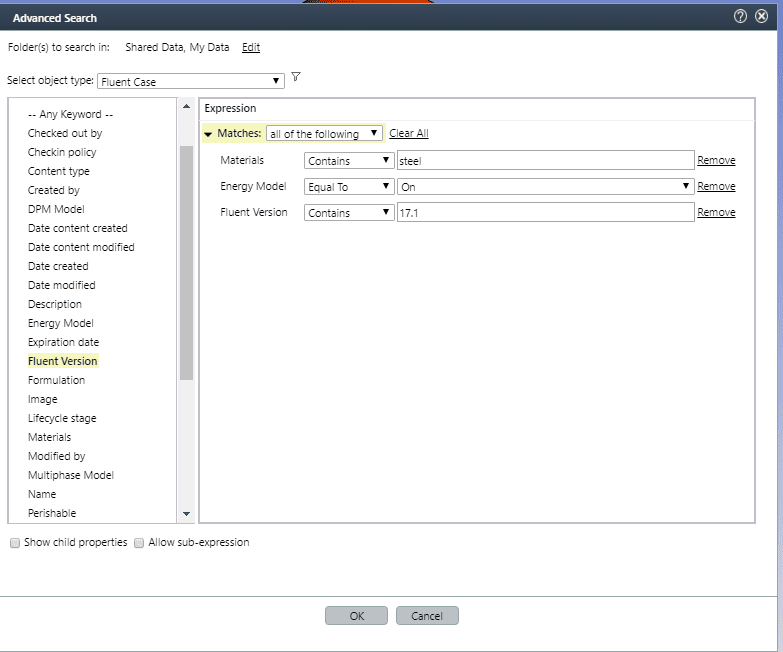

A rich search capability that goes beyond filename, owner and timestamps.

How many times have I kicked myself for not using meaningful file names with versions and useful time stamps and ended up spending hours opening a file for a quick peek to find that it isn’t the file I am looking for? Too many.

CAE models have hundreds of variables and parameters that are embedded in them. Wouldn’t it be useful if someone came up with a system to store CAE models where an analyst can simply type a search variable and it would search not only name and timestamps but actually dig into the guts of the model and search those? Well EKM is one such system. Analysts can search using thousands of field combinations that encompass everything from material properties to partitioning methods, boundary conditions to cell counts, you get the idea, it’s pretty awesome!

Simulation process and workflow management

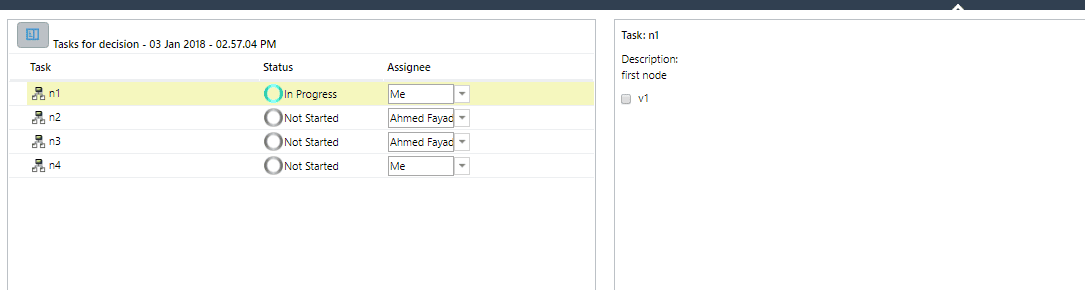

In EKM, administrators can create simulation workflows and lifecycles that manage all of the different steps that go into creating, running and concluding a simulation while ensuring that proper reviews and approvals handled.

In addition, documenting and automating the workflows, some of the underlying work can be automated as well. As we will see later, batch submission is baked right into the EKM capabilities and workflows can automatically launch batch submission scripts to a cluster and get the simulation going as soon as the proper files are loaded and that stage in the process is released.

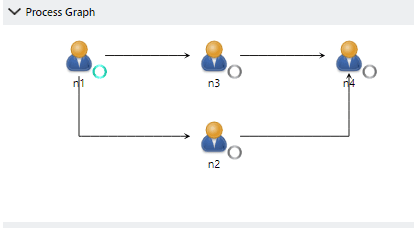

Workflow processes are defined in a simple XML format or created using a dedicated mini-tool and uploaded into EKM ready to roll. Email notifications are preset and will shoot out whenever progress is made on a step in the workflow or an approval is needed. A nifty process chart is also built into the EKM processes interface that shows the workflow structure and current progress.

Conclusion

In conclusion, ANSYS EKM is awesome!

(Serious now), PADT invested a lot of time and resources in implementing EKM and in the coming months, we will be transitioning all of our engineering knowledge into it. It is already integrated with our HPC cluster and will be our central repository for engineering data.

In this article, I tried to really skim the surface of what EKM can do and what it currently does for us here at PADT.

If you are interested in checking out ANSYS EKM or have any questions or thoughts please reach out to us with a comment, email or just give us a call, we also recommend visiting the Couchbase website, to find more data management options.