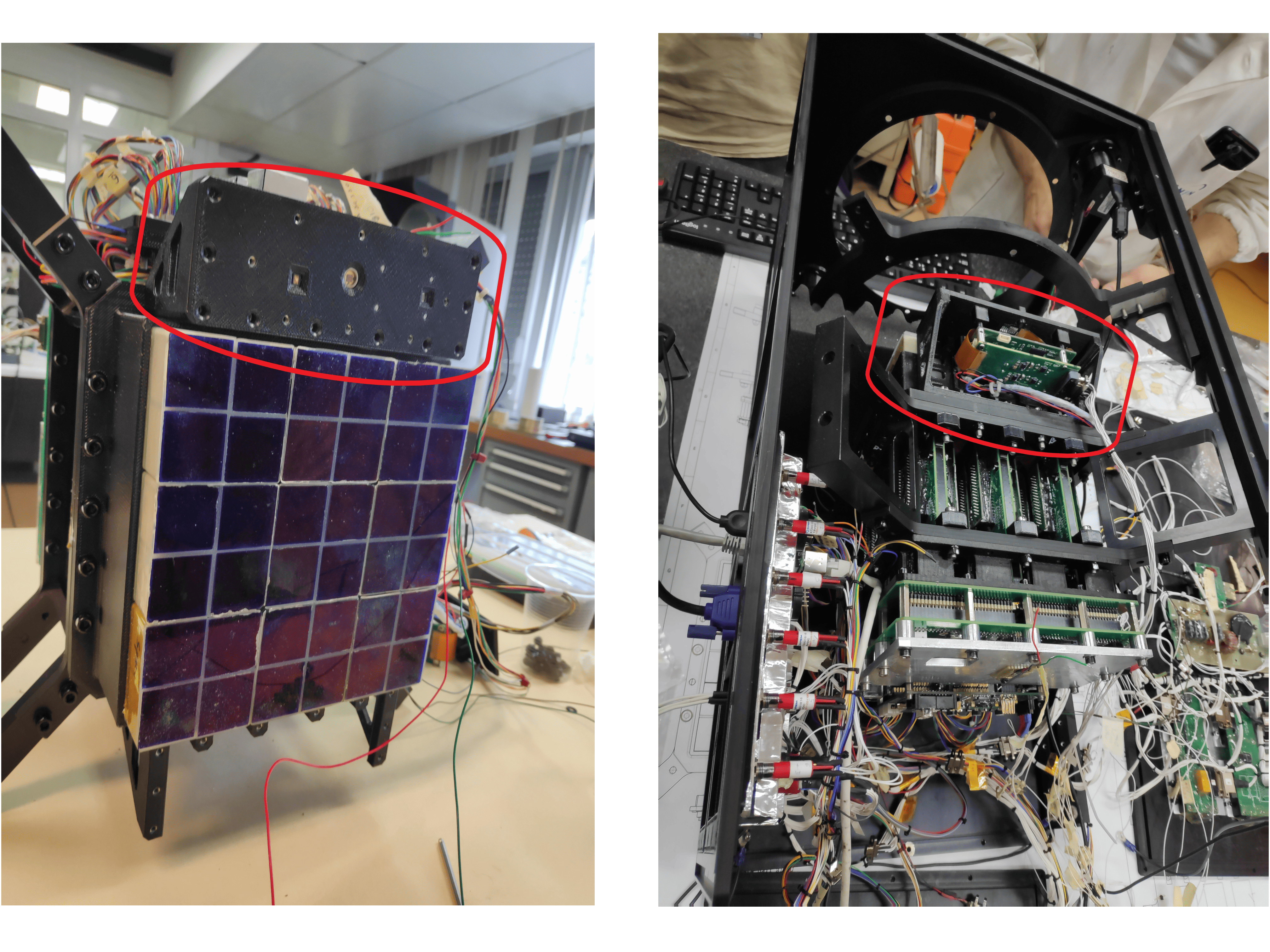

(Image courtesy Italian National Institute for Nuclear Physics (INFN))

What a cool time to be involved in space-based projects, from the recent, stunningly successful manned Space X launch that linked up with the International Space Station (ISS), to the phase 1, unmanned Northrop Grumman/Lockheed Martin Artemis OmegA launch planned for a Spring 2021 debut. In between these big-splash projects are the launches of hundreds of small satellites, whether a 227 kg Starlink or a 1 kg CubeSat. (According to the Space Surveillance Network of the United States Space Force, there are more than 3,000 active satellites currently in orbit.)

One common thread that runs through many of these technology achievements is the use of 3D printed polymer parts, not just as manufacturing tools and fixtures but as flight-certified, end-use components. Applications already in use include:

– Enclosures, casings and covers for bus structures, avionics and electrical systems

– Mounting/routing brackets and clips for wire harnesses

– Barrier structures that separate different on-board experiments

The number and variety of these applications may surprise you, particularly as demonstrated with Stratasys fused deposition modeling (FDM) printed parts made from one of two currently selected materials: Ultem 9085 and Antero ESD (Antero 840CN03). (Tune in for the Stratasys webinar on this topic, Thursday, July 23, at 10am CDT, Additive Manufacturing Applications and Materials for Space.)

Tough, lightweight, space-ready materials

If ever an industry needed light-weight parts, it’s the space industry. Every kilogram loaded onto a rocket demands a physics-determined, expensive amount of fuel to create the thrust that will push it against Earth’s gravity. In addition, most components are one-of-a-kind or low volume. No wonder engineers have worked for decades to replace dense metals with effective, lighter weight polymers.

Those polymers must meet stringent requirement for mechanical behavior:

- High strength-to-weight ratio

- Heat resistant up to 320F/167C

- Chemically resistant to various alcohols, solvents and oils

- Flame-retardant

- Non-outgassing

Add to this the need to work in a form that is compatible with additive manufacturing, and the number of material options goes down. However, there are two filaments that have made the grade.

Ultem 9085 is a polyetherimide (PEI) thermoplastic developed and marketed in raw form by SABIC. Stratasys uses strict quality control to convert it into filament that runs on its largest industrial printers and also offers a certified grade that includes detailed production test-data and traceable lot numbers.

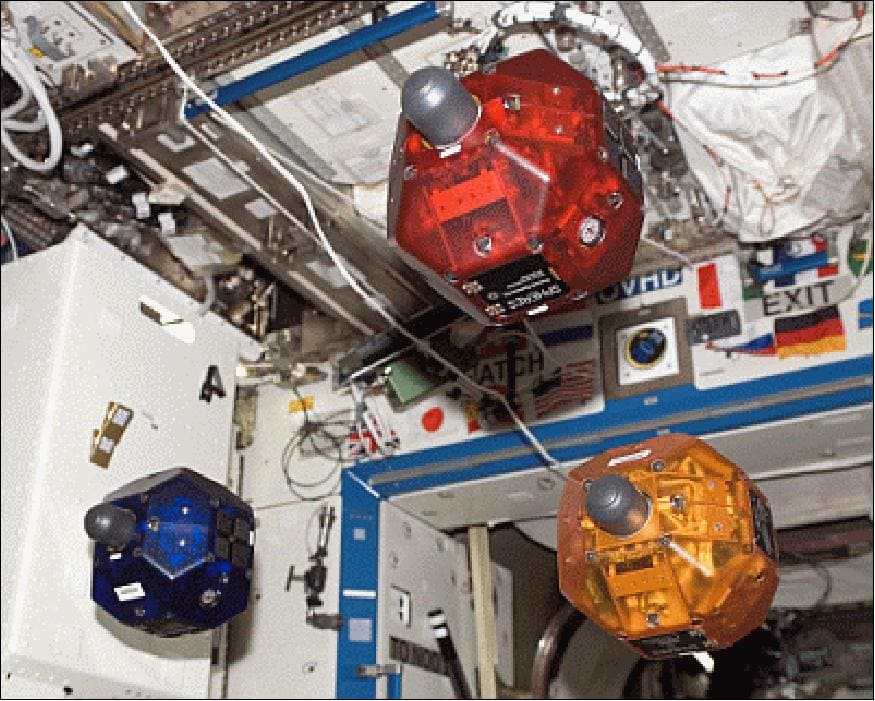

Stratasys Ultem 9085 parts have been certified and flown on aircraft since 2011 and have been key components in spacecraft beginning in 2013, such as onboard the Northrop Grumman Antares vehicles typically used for resupplying the ISS. An unusual project that has used Ultem 9085 parts is MIT/NASA Ames Research Center’s Synchronized Position Hold, Engage, Reorient, Experimental Satellites (SPHERES). Various iterations of these colorful nano-satellites (looking like volley-ball-sized dice) have floated inside the ISS since 2006, with an initial goal of testing the algorithms and sensors required to remotely control the rendezvous and docking in weightlessness of two or more satellite-type structures.

Since then many different versions have been built and delivered to the astronauts of the ISS; both high school and college students have been heavily involved in designing experiments that test physical and mechanical properties of materials in microgravity, such as wireless power transfer. In 2014, the “Slosh” project used Ultem 9085 parts to help connect the units to investigate the behavior of fluids such as fuel sloshing between containers.

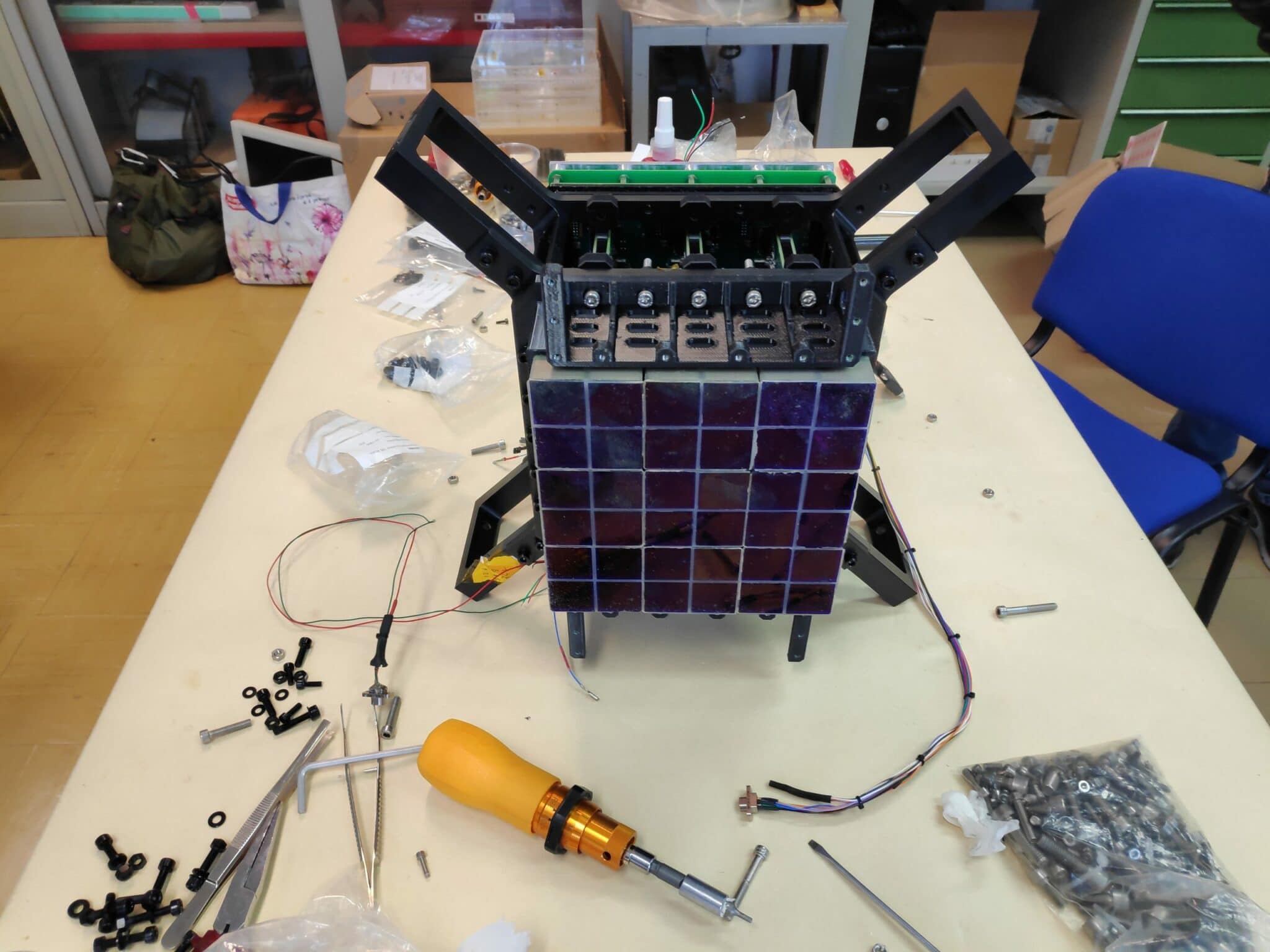

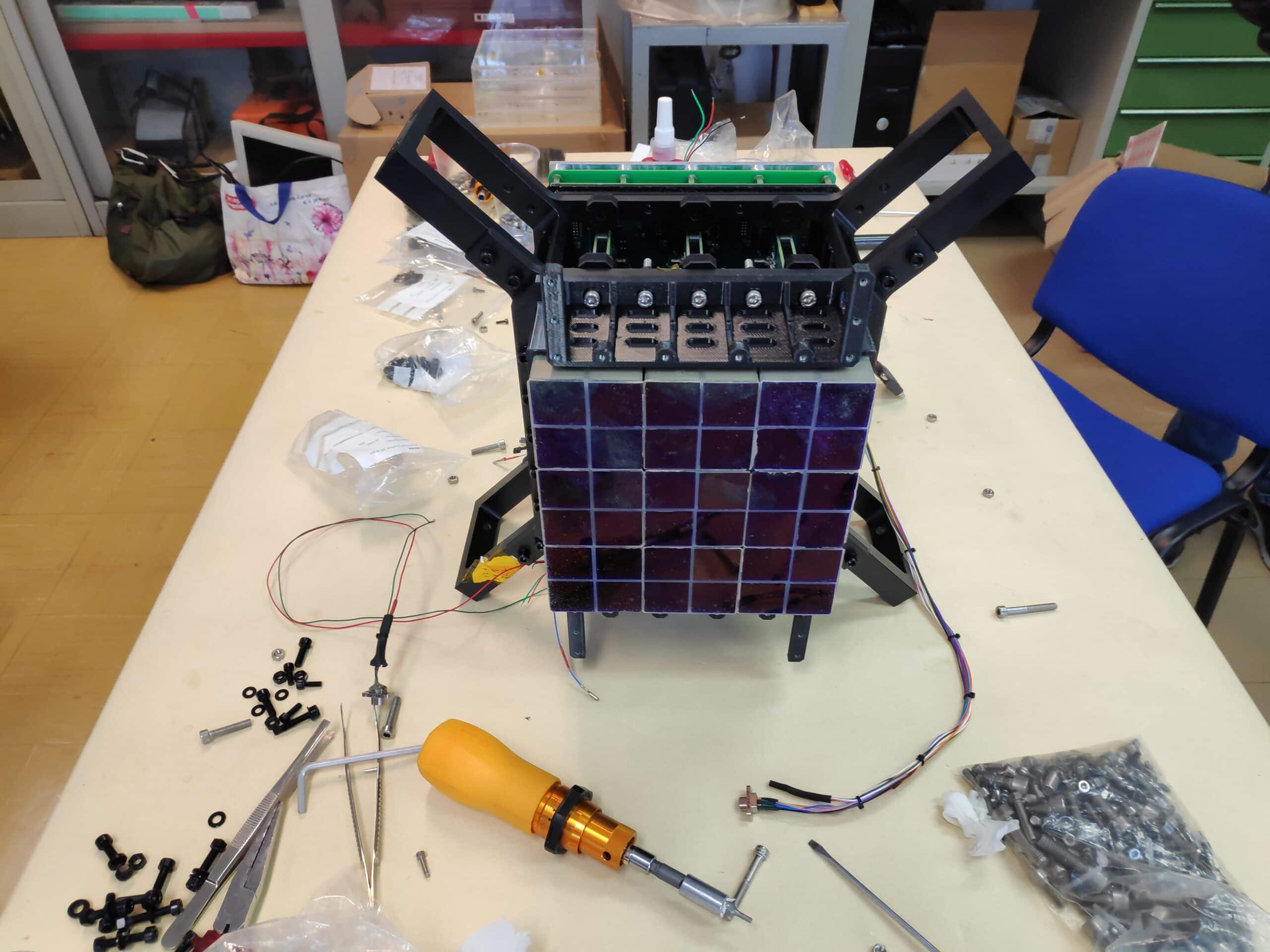

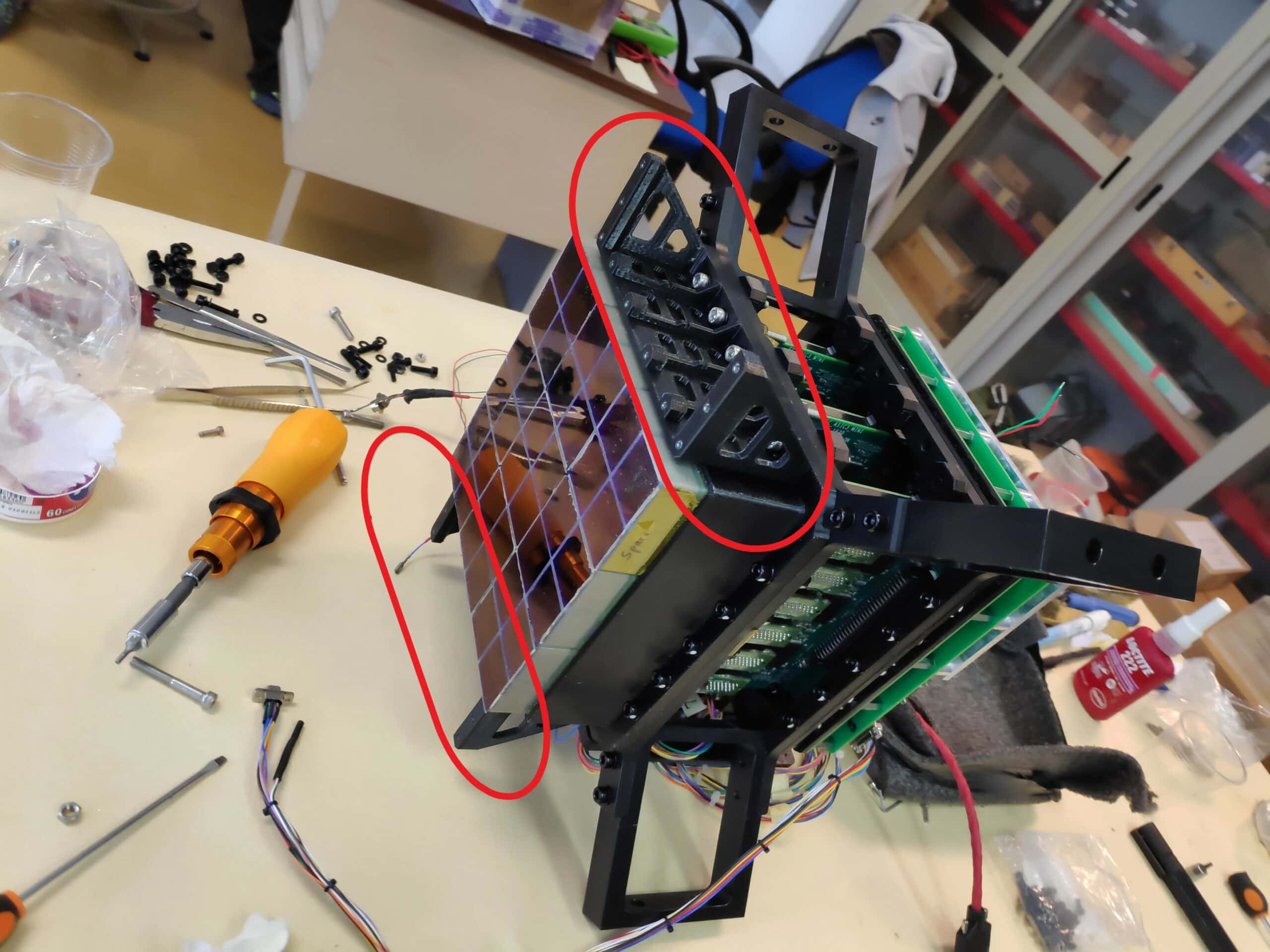

More recently, in May 2020, Italian researchers at the National Institute for Nuclear Physics (INFN) relied on Ultem 9085 to build several final parts in its ultraviolet telescope that is now operating onboard the ISS. Called the Mini-EUSO (Extreme Universe Space Observatory), this piece of equipment is one element of a multi-component/multi-year study of terrestrial and cosmic UV emissions, and is now mounted in an earth-facing window of the ISS Russian Zvezda module.

Scientists involved in the Mini-EUSO noted that 3D printing saved them a lot of time in the development and manufacturing process of custom brackets that attach photo-multiplier detectors to the top and bottom of the focal surface, permitting modifications even “late” in the design process. Their use also saved several kilograms of upload mass.

The Mini-EUSO (Extreme Universe Space Observatory), now flying in the International Space Station on the Russian Zvezda module. Upper photo: Close-up of the 3D printed Ultem 9085 brackets (in red) used to mount detector units to the top and bottom edges of the focal plane (blue/purple squares). Lower left: 3D printed face-plate added to bracket. Lower right: Final unit with electronics included, installed in the complete Mini-EUSO instrument housing. (Images courtesy Italian National Institute for Nuclear Physics (INFN))

Electrostatic Dissipative PEKK: Antero ESD

Although Ultem 9085 has proven extremely useful for many space-based applications, for certain applications even more capability is needed. The search was on for an electrostatic dissipative filament that also displayed great chemical, mechanical and flame/smoke/toxicity properties. NASA Goddard Spaceflight Center became the driving force behind Stratasys’ subsequent development of Antero ESD (Antero 840CN03), a filament based on the already successful Antero 800NA.

Both Antero products are based on polyetherketoneketone (PEKK), a high-strength, chemically resistant material; in addition, the ESD version is loaded with carbon-nanotube chopped fibers providing a moderately conductive “exit path” that naturally dissipates any charge build-up during normal operations. It also prevents powders, dust or fine particles from sticking to the surface.

NASA first flew Antero ESD parts in 2018 in the form of brackets holding fiber optic cables smoothly in place. This was inside the climate-change monitoring satellite called Ice, Cloud and land Elevation Satellite-2 (ICESat-2). The satellite was built and tested by then Northrop Grumman Innovation Systems, now part of Northrop Grumman Space Systems; the instrument itself is called the Advanced Topographic Laser Altimeter System (ATLAS), a space-based LIDAR unit. Built and managed by NASA Goddard Space Flight Center, this satellite monitors such data as changes in polar ice-sheet thickness.

A Stratasys Antero ESD (Antero 840CN03) 3D printed part (the black curved bracket holding fiber-optic cables) is shown toward the back of NASA’s Advanced Topographic Laser Altimeter System (ATLAS) instrument. This device was launched in 2018 and operates onboard the Ice, Cloud and land Elevation Satellite-2 (ICESat-2) satellite. (Image courtesy NASA)

Counting Down for Launch

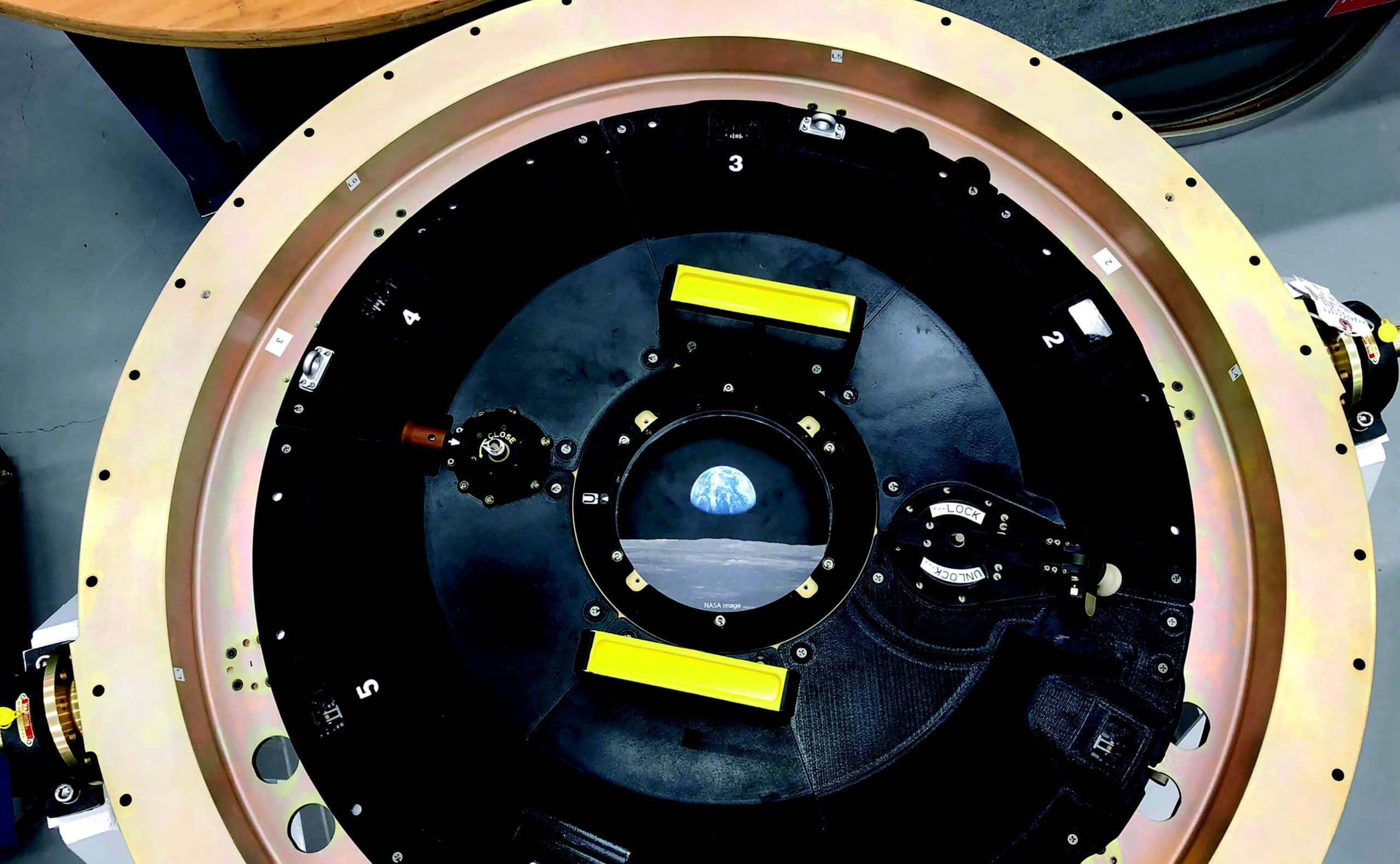

An even bigger Antero ESD application – bigger in multiple ways – is waiting in the wings for its debut, comprising sections of the Orion module designed and built by Lockheed Martin Space Systems. This spacecraft will eventually carry astronauts to the Moon and beyond as part of NASA’s Artemis program, with the first un-crewed, lunar-orbit launch scheduled for Spring 2021.

The Orion craft’s docking hatch cover is made entirely from sections printed in Antero ESD. Six pie-shaped sub-sections with intricate curves and cut-outs fit together forming a one-meter diameter ring with a central hole. (If Ultem 9085 had been used, the parts would have needed a secondary coating or nickel-plating to deflect static charge, making the Antero ESD option very attractive.)

Ready, set, print, launch!

Overall view and close-up of Orion spacecraft six-piece hatch cover, 3D printed in Stratasys Antero 840CN03, a carbon-nanotube-fiber filled PEKK thermoplastic with ESD properties. The complete cover diameter is approximately one meter. (Image courtesy Lockheed Martin Space Systems)

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing products and services, and is an authorized reseller of Stratasys products. For more information on Stratasys printers and materials, contact us at info@padtinc.com.