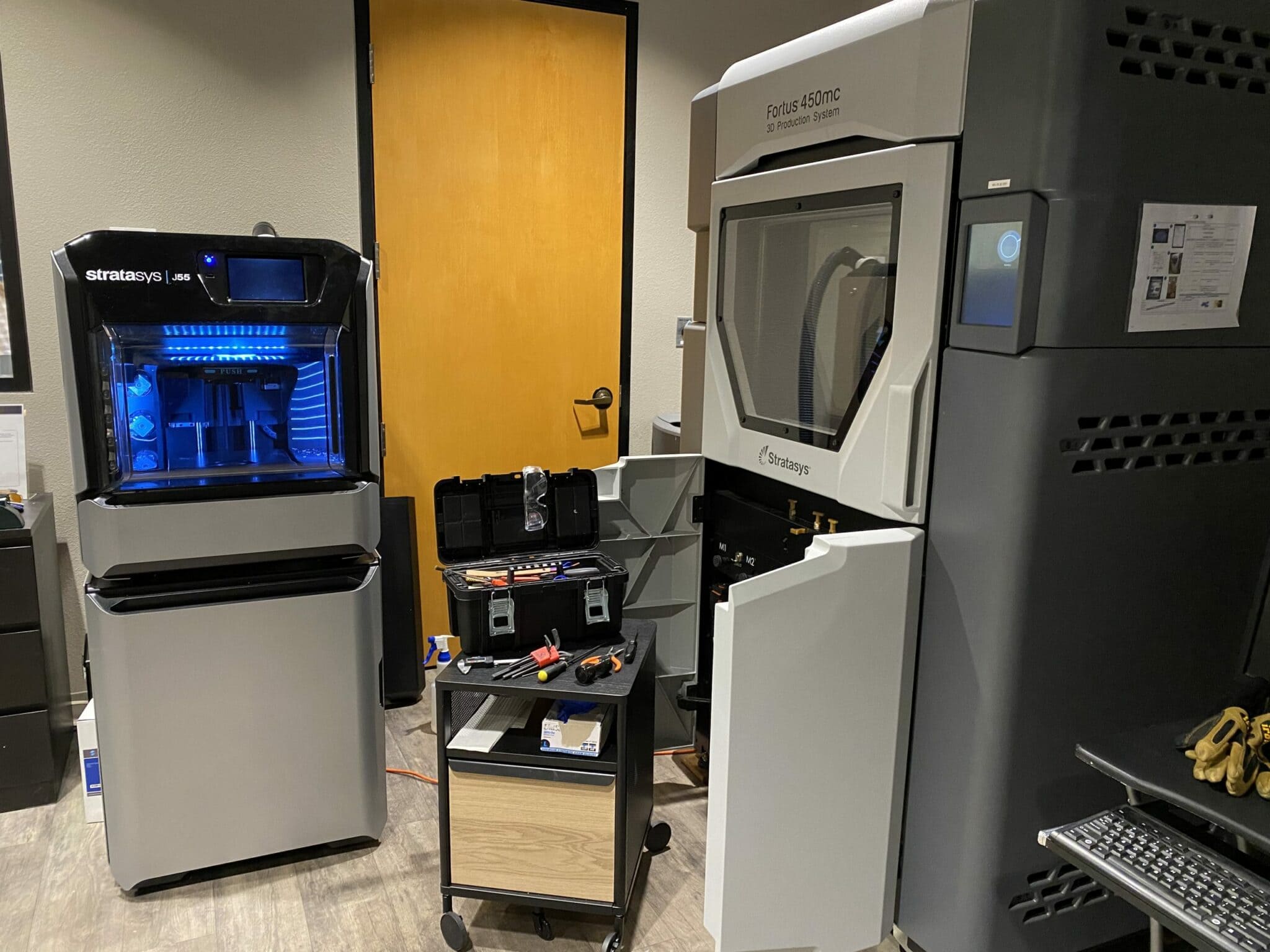

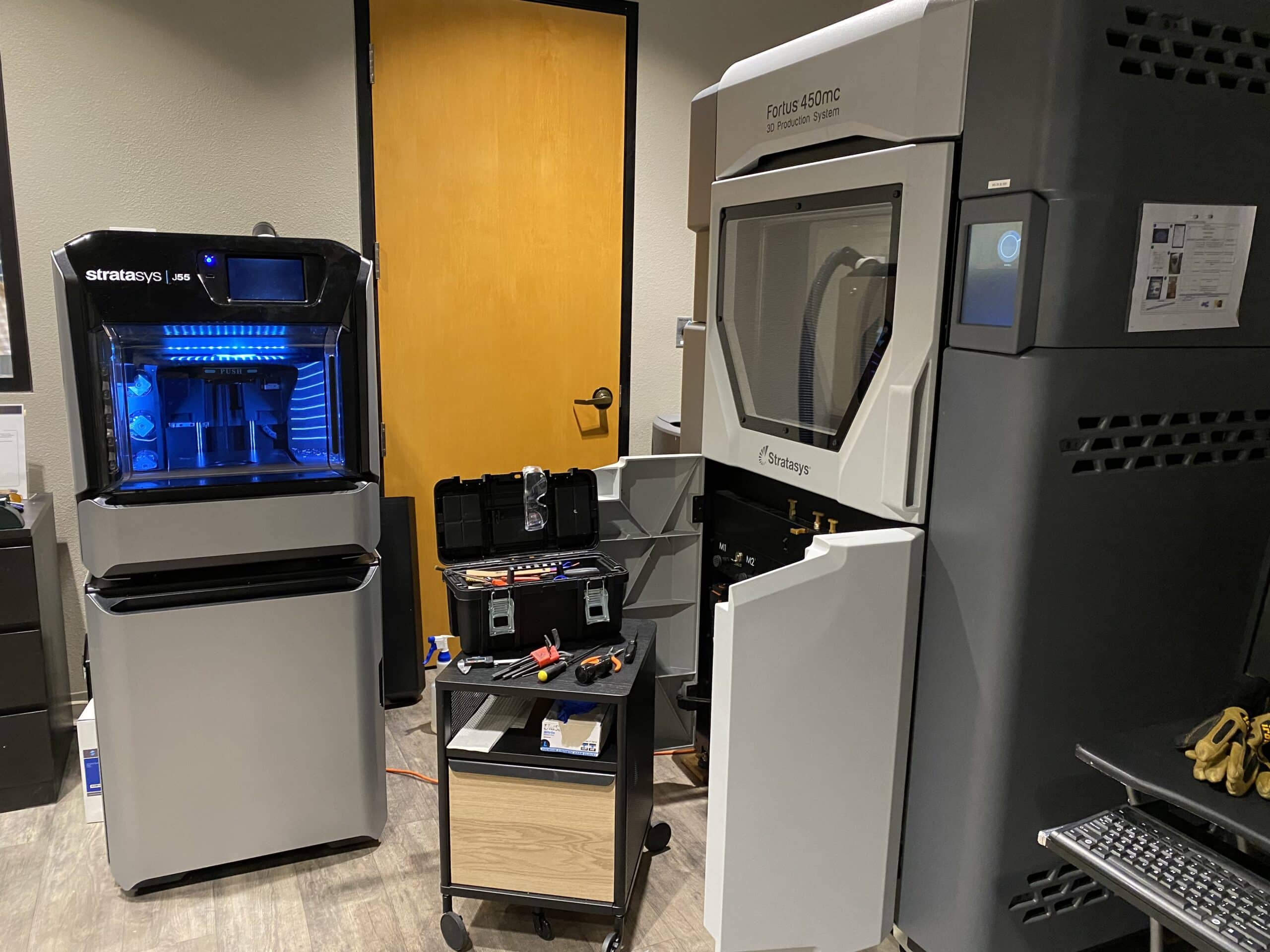

Just over a year ago, PADT, like most every other engineering company, shifted rapidly into minimal on-site-operations mode. As the PADT 3D Printing Application Engineer, I worked from home while requesting support from our manufacturing group for running benchmark parts on our Stratasys fused deposition modeling (FDM) filament and PolyJet resin printers. Whether those parts were created on the F370, F450, F900 or J55 printers, they spanned a wide range of part size, function and material. It was an interesting time, but software tools like GrabCAD Print made remote part set-up possible, and the on-site team kept everything running under some often-challenging conditions.

I’ve been back in the office for about a month, so I’m tending to tasks that were, out of necessity, put on a backburner while our company did high-importance projects such as printing a ton of PPE visor frames. Now it’s time to do some printer maintenance that got a little delayed beyond the recommended run-time schedule.

For our Stratasys J55 full-color PolyJet printer, while all the standard components were cleaned and checked after every print, we stretched the recommendation period for replacing the wiper blade, the roller-waste collector, and both filters in the compact ProAero Air Extractor that contributes to making this printer truly office-friendly. Now I’ve checked those off as done.

Bring in the Printer Maintenance Experts

Other steps should only be done by a professional from the Service Department at your reseller or from Stratasys. When they come on-site to perform Preventive Maintenance for your printer, do you know what goes into this, and the kind of tasks that keep your system humming along?

It’s similar to practicing good automotive ownership: checking the air in your tires, changing the oil every 5,000 miles or so, replacing brake pads before they’re so thin that you have to turn the rotors, etc. Some jobs you do monthly, some yearly and some on general principles to avoid future trouble which inevitably occurs during the critical stage of a project.

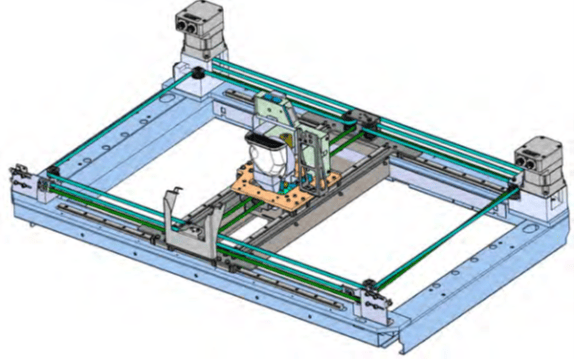

Here are some of the tasks our PADT service technician performs from the 12-month Preventive Maintenance Checklist for a Stratasys F450 industrial FDM printer:

- With the printer powered off, clean the canister drives, gantry fans and electronics bay ventilation fans (kind of like cleaning out the ventilation area under the front of your refrigerator – which we all do regularly, right?) Also, inspect the head cable and heat shields, verify X-Y belt tensions, and replace the vacuum filter.

- With the printer powered on, verify voltage levels, fan speeds and Z-Zero calibration, inspect the flicker brush assemblies and clean and lubricate the Z-axis leadscrew.

When the two-year point rolls around, these tasks are repeated plus another set is added, such as:

- With the printer off: Replace the filament guide tubes, Kapton seals, X and Y bellows seals, oven lamps, air-pressure regulator diaphragm and all compressed-air system filter elements.

- With the printer on: Adjust the air pressure and airflow, verify the oven blower operation and perform filament load-time tests.

And at the four-year mark, all of the above are completed plus such tasks as “replace the X and Y belts.” At every service appointment, too, the technician verifies that the current version of the printer control software has been installed, and that the user has the latest application software, whether Insight or GrabCAD Print. All in all, we’re talking more than 50 check points and tasks that keep the printer running smoothly.

High Expectations from Good Maintenance

I have to admit that when I get into my car, I expect the engine to idle smoothly, the air-conditioning to generate chilled-air, and my driveway to be free of oil spots. However, that expectation is only realistic if I or my mechanic has done due diligence with regular inspections and taken action when certain conditions show up. Checking for dirty spark plugs or a cracked distributor cap will maintain engine performance. If the serpentine belt is showing signs of wear, I’d better replace it rather than risk losing both power steering and air-conditioning on some far-off road in the desert on a beastly summer day. And worn rings, pistons or gaskets could all contribute to that oil leak.

And so it goes with 3D printers. First, the importance of avoiding down-time is huge for most manufacturers and factors into both production planning and a smooth workflow for printing prototypes. Second, if you’ve paid for a Stratasys-authorized Service Plan, you get guaranteed response time when something does go wrong (say you accidently melted filament into the print-head because you didn’t mount the tip correctly – life happens). Third, with a PM contract, a trained technician steps you through every aspect of the printer’s operation, inspection and cleaning whether done daily/weekly/monthly by a program engineer or by the system operator.

Stratasys offers three levels of contract service for almost all of its 3D printers, now covering the gamut from FDM and PolyJet to SLA, DLP, and the new Selective Absorptive Fusion (SAF, a polymer powder-bed fusion technology). Those levels are Sapphire, Emerald, and Diamond which can each be purchased for multi-year coverage.

Generally speaking, service offerings include:

- On-site technical service

- Spare parts

- Priority service scheduling

- Discounted user-training

- Discounts on printer heads

Customers also win with hardware updates, optional backup printing services, predictable maintenance expenditures for easier budgeting, and more.

It’s not in my budget to buy a new car every year or even every couple of years, so regular, professional automotive inspection and maintenance is critical to me. It is to customers in the additive manufacturing world, too. So, to paraphrase that diamond-jewelry advertisement, “Now you have a friend in the 3D printer business: Stratasys.” Find out more about service contracts and the details of preventive maintenance by contacting 3DPSAL@PADTinc.com.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing products and services. For more information on Stratasys printers and materials, contact us at info@padtinc.com.