Tracking time has challenged the human race for centuries, resulting in some of the finest mechanisms ever crafted. From sundials and hourglasses to pocket watches and atomic clocks, we have marked the passage of time with ever-increasing precision. Along the way, we became supremely skilled at creating the requisite gears and springs, as well as the machines to produce them. (If you have a deeper interest in measuring time, one must-read book is Longitude by Dava Sobel.)

This post, however, is about taking clock-making to a new dimension – three dimensions, in fact, using multiple 3D printers to generate not only the gears and structural components but even the watch-spring and winding-key, based on a mechanism called a Tourbillon. Invented around 1800 by Abraham-Louis Breguet, the Tourbillon concept compensates for the effects of gravity on delicate watch-springs when the watch is carried or laid down (varying its orientations), by employing multiple axes.

An excellent write-up on this concept is on MyMiniFactory, which is also where you’ll find the fascinating design of a 3D-printable Tourbillon clock from a designer called Mechanistic. Check out this mesmerizing video of the clock in action. Mechanistic has previously done other awesome designs and this past Spring did a crowd-funding effort to support printing all the components on a hobby-type 3D printer.

Depending on one’s donation amount, some or all of the intricate clock’s CAD files are downloadable. Recently Justin Baxter, PADT’s senior 3D Printing Service Engineer (with years of hobbyist clock-making under his belt), set out to reproduce the device with a twist. Why not take advantage of all the additive manufacturing systems in use by PADT’s Manufacturing Division, and print at least one component on each?

This approach spans the AM technologies of Fused Deposition Modeling (Stratasys FDM material extrusion), PolyJet (Stratasys material deposition), selective laser sintering (3D Systems SLS polymer powder bed fusion), direct metal laser sintering (EOS DMLS metal powder bed fusion), stereolithography (3D Systems and UnionTech vat SLA photopolymerization) and digital light processing (Stratasys Origin One DLP vat photopolymerization).

The Triple-Axis Tourbillon Mechanical Clock Design

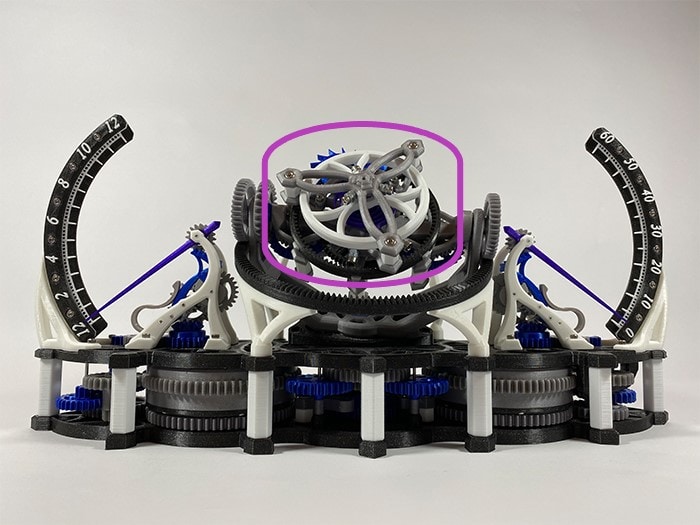

Not all of the clock’s 230 components are 3D printed – metal screws, pins and ball bearings round out the assembly – but Justin is slowly printing all other parts spread across colors, materials and AM technologies. For starters, he has recreated the central first-axis mechanism called the Mini Mechanica; this subset serves well for new users to test out their own systems and parameters ensuring effective dimensional tolerances. The Mini Mechanica part files are also available as a separate free download.

Justin’s Mini Mechanica includes the following parts made of ABS (acrylonitrile-butadiene-styrene), each 3D printed on one of our two Stratasys F370 FDM systems:

| Part Name |

| 01_Bottom Base |

| 02_Upper_Base |

| 03_Tourbillon_Lower_Cage |

| 04_Tourbillon_Upper_Cage |

| 05_Cage_Bridge |

| 06_Cage_Spacer |

| 07_Ratchet_Post |

| 08_Winder |

| 09_Mainspring |

| 10_Core_Post |

| 11_Impulse_Pin |

| 12_Tourbillon_Ring_Gear |

| 13_Hairspring |

| 14_Balance_Wheel |

| 15_Escape_Fork |

| 16_Escape_Wheel |

| 17_Washer |

| 18_Display_Stand |

When finished, here is how that subset will fit into the completed three-axis clock:

Note: the fully printed clock operates on a 90 minute run-time if a steel spring is employed, and 20 minute run time with a 3D printed (FDM) version. (We’ve seen suggestions for adding a battery.)

For more details on the Triple Axis clock, see the conveniently provided assembly guide: (2) How to build a 3D Printed Triple Axis Tourbillon | Assembly Guide – YouTube.

As the part-builds progress across our other printers and materials, we’ll post an update. Here are a few more components in progress, including the decorative base on the left, which was printed in Nylon 12GS on our SLS powder-bed printer.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing products and services. For more information on Stratasys polymer printers and materials and EOS metal printers, contact us at info@padtinc.com.