PADT is starting a new blog series highlighting the industries we serve, our hard-earned expertise, and the unique capabilities we offer across a wide variety of both commercial and consumer product sectors. In today’s blog, we’ll be talking about an industry from which PADT was founded…the aerospace industry.

Check out the second entry, on Medical Device Development.

Over 25 years ago, four aerospace engineers working on turbomachinery came together and realized that the skills they had developed across aerospace design, analysis, and rapid prototyping could be expanded to a wide range of industries to help create better products. In the summer of 1994, they left their corporate jobs to form Phoenix Analysis and Design Technologies, Inc., better known as PADT. 28 years later the company is still going strong and applying its skills and tools, formerly dedicated to aerospace, across the product development landscape.

PADT had this dream of bringing aerospace tools and processes to all industries, but it always retained the expertise of working with aerospace innovation. Today, the company counts some of the world industry leaders in this sector among its customer base and offers a wide variety of products and services for the design, simulation, and prototyping of aerospace vehicles, components, and more.

Product Offering

PADT is a reseller of 3D printers and simulation software from Ansys and Stratasys respectively, along with several other compatible engineering tools. We offer a wide variety of tools designed to help aerospace engineers and manufacturers test and qualify designs, prototype components and enhance the overall product development process.

Another critical tool used in the aerospace industry for product design and testing is simulation software. Aerospace simulation forms an integral part of aerospace development, from the design of aerospace vehicles, systems, and operations; human factors studies; accident investigations; to studies aimed at improving aviation safety and efficiency.

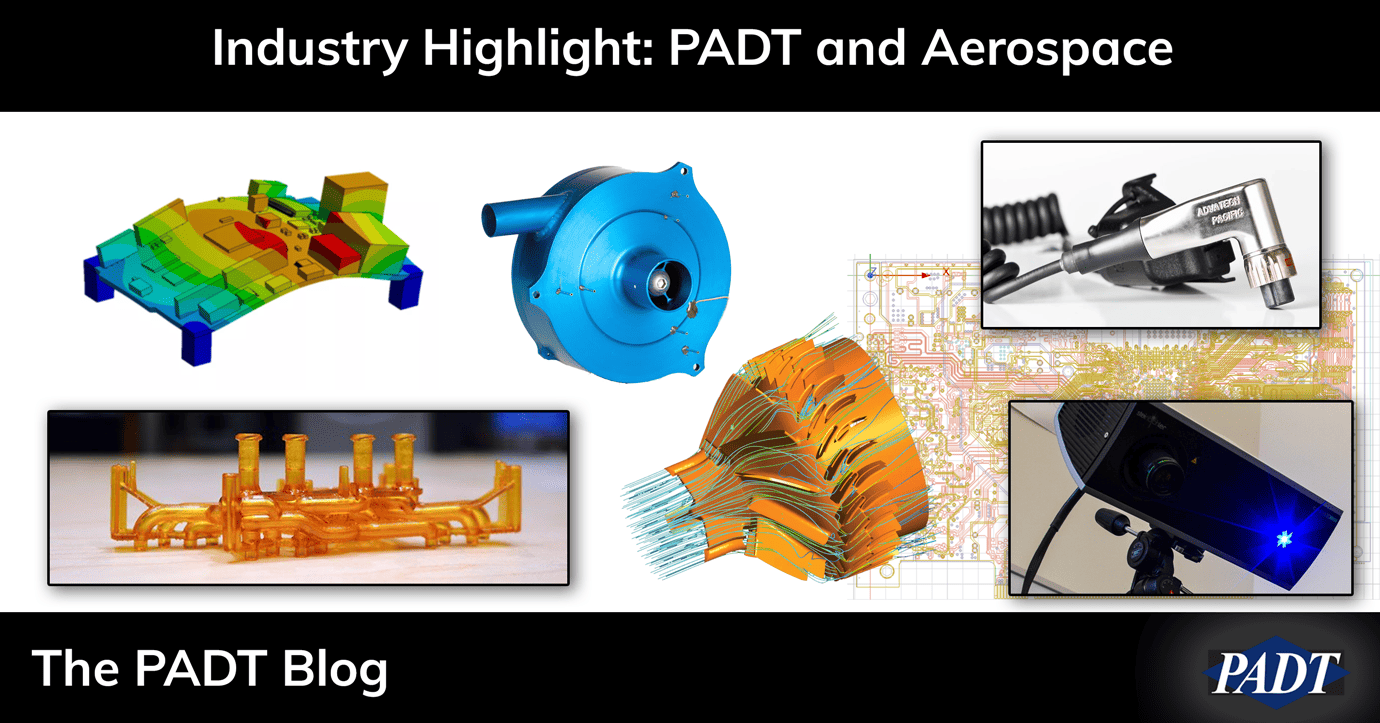

PADT offers two of the leading simulation tools on the market in the aerospace industry and beyond. The first, Ansys, offers a wide range of solutions delivering significant product lifecycle cost reductions that the industry demands while accelerating technological innovation. As an Ansys Elite Channel Partner, PADT supports almost every physics an aerospace part of the system encounters including structural, fluids, thermal, electromagnetics, acoustics, and optics. The second tool, Flownex, delivers simulation software that enables customers to study how flow and heat transfer systems will behave in the real world, where fluid is the driving factor.

Our simulation team also provides technical support and training based on many years of combined simulation experience. The customer support team has won awards for its dedication to making our customers successful users of simulation solutions.

3D printing and the capabilities it offers in terms of both prototyping and real-use parts are growing rapidly. Stratasys is the world leader in Additive Manufacturing solutions and PADT has been working with these systems as a Diamond Partner and service provider from nearly the beginning. Similar to PADT, 3D printing and Stratasys were founded within the aerospace industry over 20 years ago.

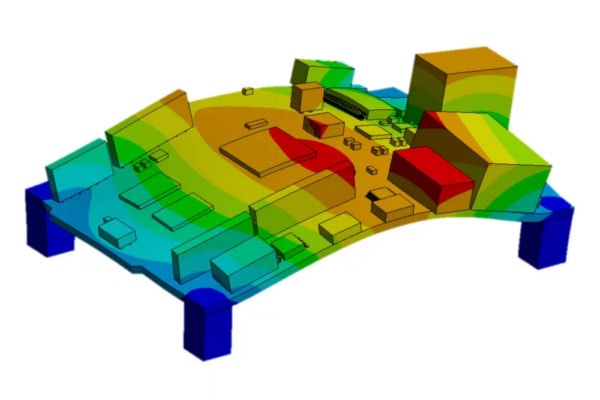

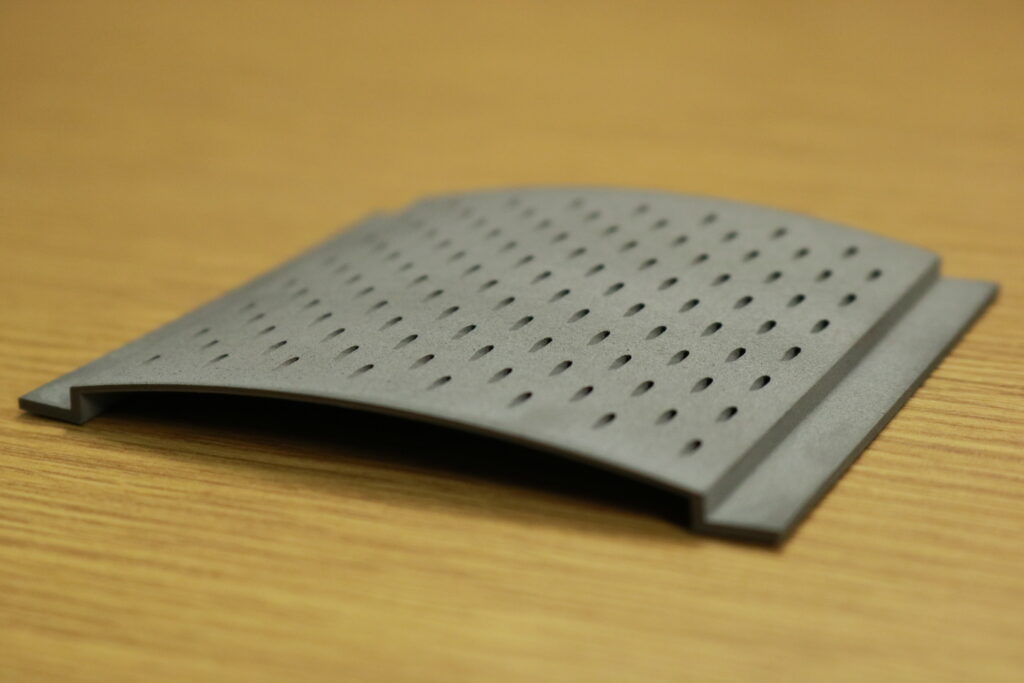

Stratasys tools are the dominant solution for aerospace because of the dependability and consistency of the machines and the large selection of engineering materials that can be used for not just prototypes, but for tooling and flight hardware. PADT is helping its customers explore the growing uses of additive manufacturing through the world’s leading systems from Stratasys, offering Stratasys’ complete lineup to meet every customer’s needs.

One of the fastest-growing areas of additive manufacturing is metal 3D Printing. PADT has partnered with EOS, the worldwide leader in metal Laser Powder Bed Fusion systems to supply the best solutions backed by PADT’s technical expertise. EOS has become the preferred supplier in aerospace because of the repeatability and reliability of the components manufactured in its systems. They also offer a wide range of metal powders that are certified and tracked so that components made on EOS systems are not only used for prototyping and tooling, parts are now flying in the sky and in space

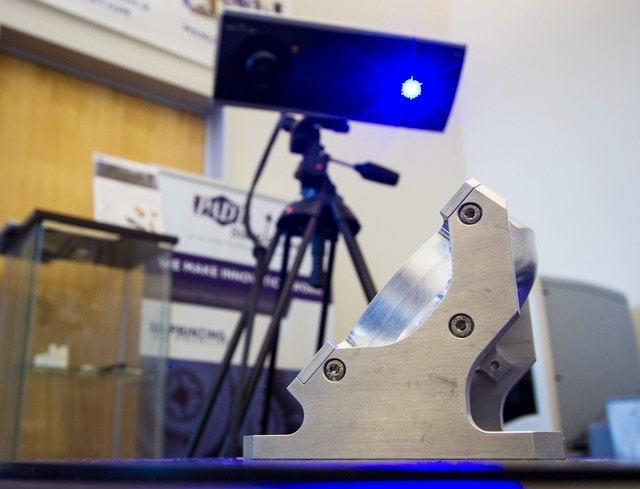

PADT has also added 3D scanning systems to our portfolio to meet the needs of our aerospace customers that require accurate non-destructive testing, offering the leading optical scanning solutions from ZEISS and GOM’s #handsonmetrology line.

Engineering and Manufacturing Services

Not only does PADT sell the tools that enable innovation, but we also provide services to directly help our customers design, develop, prototype, and test new aerospace products. We start with engineering fundamentals and then add the right tools, strong project management, and experience to deliver for our customers. We also partner with a network of approved consultants and companies to add capability and bandwidth when needed.

When our customers need help designing their products, they count on our Product Development Consulting team. Our product development process consists of five steps – define, conceptualize, develop a preliminary design, refine details, and transition to manufacturing. Our process and capabilities also work hand in hand with other capabilities at PDAT to get our customer’s products to market faster.

Over the years, PADT has also developed a project management methodology based on flexibility as well as frequent and open communication. Working as a team with the customer and vendors, or project managers plan, monitor, and manage in a balanced and adaptable way. This approach has proven to be extremely effective for our customers, meshing well with their internal processes and giving them the confidence that PADT’s team will meet schedule, budget, and performance specifications.

One of PADT’s key capabilities is multiple and multiphysics simulation consulting, including stress, vibration, explicit dynamics, thermal, CFD, and electromagnetics. Or, any combination of those physics. Our team consists of long-time engineers from a wide variety of backgrounds. We speak the language, so our customers can fire and forget or integrate our team into their team to get actionable information from the simulation they ask us to do.

Rounding out our services offerings is a full and complete 3D Printing services team. As of June 2022, PADT offers eight different 3D Printing technologies in-house: SLA, FDM, SLS, P3, LCDP, SAF, Polyjet, and Metal Laser Powder Bed Fusion. Each of these devices runs with multiple materials. As in other services that PADT offers, what makes our Additive Manufacturing services more valuable to our customers is the quality of our engineers. When PADT prints your parts, you can an expert advisor on the right process, material, and postprocessing.

Rounding out our services offerings is our Scanning Team. We use the same GOM and ZEISS equipment and software we sell to deliver the type of geometric data you have been looking for. Our engineers, who are also trained design engineers, understand what the data will be used for and make sure you have more than just a giant point cloud. You can bring your parts to PADT, or they can come to you.

AS9100D/ISO9001:2015 Certified Digital Manufacturing QMS

Finally, PADT’s digital manufacturing services operate under AS9100D/ISO9001:2015 certified quality management system (QMS). Our team of experienced manufacturing engineers are experts in polymer and metal additive manufacturing and work with some of the industry’s largest companies to develop manufacturing processes, certify material, and qualify parts. The team also offers optical scanning under the same quality umbrella and can help coordinate the manufacturing of your prototypes, tooling, or flight hardware with one of the eight AM technologies we run in-house, or with outside vendors. PADT has the experience, tools, and QMS to operate in the aerospace industry and provide the tools and services needed to advance innovation and create great products.

We Get Aerospace

To learn more about PADT and our commitment to customers in the aerospace industry, check out our new website at www.padtinc.com. If you’re interested in seeing how 3D printing and simulation can impact your next project, give us a call at 1-800-293-7238 or send an email to info@padtinc.com.