Here at PADT I’ve had the chance to operate Origin resin DLP printers from Stratasys for more than a year, and they have rapidly become my new favorite systems. Parts printed with this “Programmable PhotoPolymerization (P3)” technology have a look and feel that is incredibly similar to that of injection-molded parts.

Origin 3D printers are open source for material choice, and already more than 500 resins have been tested on this equipment. Stratasys has fully characterized the behavior of dozens of these possibilities, all of which respond to light at 385 nanometers. Tuning the resins to this wavelength produces parts with excellent green (uncured) strength and end-use properties, in comparison to the often less-durable results from higher-wavelength materials. Parts also print fast!

I decided to print several test parts in five of the most common resins I’ve seen requested and share a few tips on set-up and processing. The three selected models are:

- An intricate design for a razor handle, that in some materials requires no supports at all

- The housing for a back-up camera on a modified Volvo S60 car (from the Girl Gang Garage Iron Maven project, in case you’ve been following that effort), and

- A PADT sample part we call the Omega Clip, that highlights a number of possible geometries and how they print; we make this part in every material on every 3D printing technology we run.

Here’s just the razor handle done in all five materials:

The five resins I tested are listed here along with some general properties and the comparative material cost for one razor handle:

| Material/Vendor | Color | Material Characteristics | Build Time (Qty 1 to 32) | Part Cost (one razor, material only) |

| BASF ST45 | Black | Rigid, general purpose | 2.9 hr | $1.27 |

| Loctite Dura56 | Black | Rigid, impact-resistant | 3.4 hr | $0.78 |

| BASF RG35 | Clear | Rigid, exceptionally smooth surface | 2.9 hr | $1.41 |

| Loctite 3955 | Black | Rigid, strong, flame/smoke/toxicity rated | 4.1 hr | $4.31 |

| Loctite IND402 | Black | Elastomer, TPU-like | 12.6 hr | $3.59 |

Working with Origin Resins

One of the most timesaving and material-efficient aspects of the Origin resins is that each formulation is a single-part liquid. This means you can use keep using a build-tray of resin over and over for about a week (that’s the recommendation though we’ve pushed it longer); an opened bottle is “fresh” for at least a month; and an unopened bottle is rated for one year of shelf-life. We also filter, re-use and top off with fresh, adding more resin as needed to a given tray.

These attributes are in comparison to other liquid resin 3D printing technologies that use two-part materials such as epoxies: these not only require mixing at the time of use but only offer a useful life of about eight hours or else they harden, so any excess resin must be tossed out at that point. In addition, any part or parts with a volume that would take longer than eight hours to build is not printable.

The Origin workflow is as follows:

1) create supports (if needed) in Materialise Magics, Autodesk Netfabb, or any other CAD/support design software (many geometries can build directly on the build-plate),

2) add the supported model to either the Origin online app or to Stratasys GrabCAD Print (GCP) which slices the file and sends it to the printer (note: (upcoming versions of GCP will include support-generation functions)),

3) set up the printer with a clean build-plate and filled resin-tray,

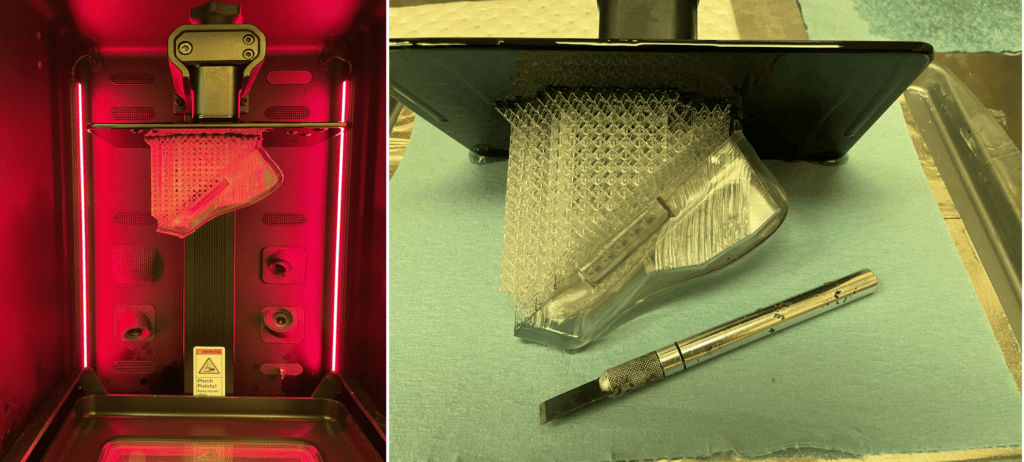

4) select and start/run the print job,

5) remove the completed parts from the build-plate, remove supports and clean the parts in IPA, and

6) UV-cure the parts (generally in under five minutes).

The only resin so far that requires one extra step is Loctite 3955. This material produces parts that can be UL-rated for flame, smoke and toxicity (FST); to achieve these properties, printed/cleaned parts require a controlled heat-treatment in an industrial oven. Once this workflow has been completed, parts offer an HDT of >300C (572F) while displaying an ultimate tensile strength of 67 MPa.

BASF Ultracur3D ST45

This material is my go-to for experimentation. Parts come out matte black, curved surfaces come out quite smooth, and, with this slightly viscous resin, unsupported overhangs of 3mm are usually fine. I’ve also printed features ranging from 1.3mm thin to 10mm thick and the sharpness is very good.

At about $0.13/cm^3, BASF ST45 serves well for testing part geometry prior to committing a model to a more expensive resin. Print time is fast and support removal is done with a flick of a fingernail.

Loctite Dura56

Dura56 resin produces parts with a very nice surface finish. It displays a higher notched impact-resistance compared to ST45 (56 J/m vs. 20 J/m) at a somewhat lower ultimate tensile strength (44Mpa vs. 53Mpa). At $0.08/cm^3, its cost is also the lowest of everything I’ve used so far.

I have had some problems with this material, due to its slightly lower green strength; this showed up, for example, with overhangs, where 2mm widths (if spanning more than about 5mm across) can produce a slight droop. If the geometry allows it, I would add more support compared to what I use for the same part done in ST45, or print it at a slight angle to make the effective surface area smaller. However, thin vertical walls or sections printing directly on the build-plate still do fine.

BASF RG35

The surface of BASF RG35 parts is exceptional! Truly sporting a satin finish, parts printed in this material have virtually non-existent layer lines – always a welcome surprise to end-users. Overhangs print great, and features/edges/corners are very crisp. As is not unusual with clear resins, the thicker the part, the slightly more “frosty-opaque” it appears; also, UV-curing adds a pinkish-gold tinge to the thicker regions.

RG35 is my favorite material when I want customers to respond with, “That’s 3D printed?” It makes a great base for painting, and the HDT is 83C (181F). Cost is about $0.14/cm^3.

Loctite 3955 FST

If your application requires using a flame-, smoke-, and toxicity-rated material that is also chemically resistant, Loctite 3955 may be your answer. Once heat-treated (a required post-processing step), this material meets such standards as UL94 V-0 and FST AITM2-0002 among others. In addition, the final HDT is greater than 300C (572F). For an application example, the Air Force is now using Loctite 3955 to print hydraulic-line clamps for F-16 aircraft.

Operators need access to a commercial oven for the heat-treatment and must follow a specific time-temperature profile for both heat-up and cool-down; the complete process takes about 8 hours, so be sure to allow a full workday for this important step. The white-wash look came from the special solvent specified by Loctite; I need to find out more about this. Also, the parts in the oven avoid warping when “weighted down” with salt. Price is $0.44/cm^3.

Loctite IND402

Origin printers can also produce parts with elastomeric properties. Think black rubber with really tough behavior: IND402 parts display 230% elongation at break with a Shore A value of 75 to 90, depending on part geometry. I recently printed very small custom gaskets in this material for a very happy customer; they are going to use their new Origin system to create thousands of end-use parts.

Setting up and printing models in elastomers does involve a bit of a different approach than for the same model in a rigid resin. First, more supports are required. You’ll find yourself adding supports where there were none or increasing the number of touch-points for supports where otherwise just a few would suffice. The reason is, as the build-head pulls back, any enclosed area, any area with small drainage holes, or an area with a sudden change in cross-section ends up experiencing a suction-force. The material stretches, and parts could otherwise pop off the build, or separate mid-way, leaving a partial model stuck to the tray.

Print times are quite a bit longer, too, because the resin’s high viscosity requires a much longer time to flow and entirely recoat the tray in between every layer (e.g., 12 seconds per layer vs. 4 seconds per layer) – that adds up, as you can see from the build-times in the comparison chart above. Material cost for IND402 is $0.36/cm^3.

PADT’s Manufacturing Services group is already running nine different Origin resins and colors with more to come. Let us know if you’d like to explore 3D printing production parts with injection-molded quality, using easy-to-operate Origin printers.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing/3D Scanning products and services. For more information on Stratasys printers and materials, contact us at info@padtinc.com.