3D Scanning Overview

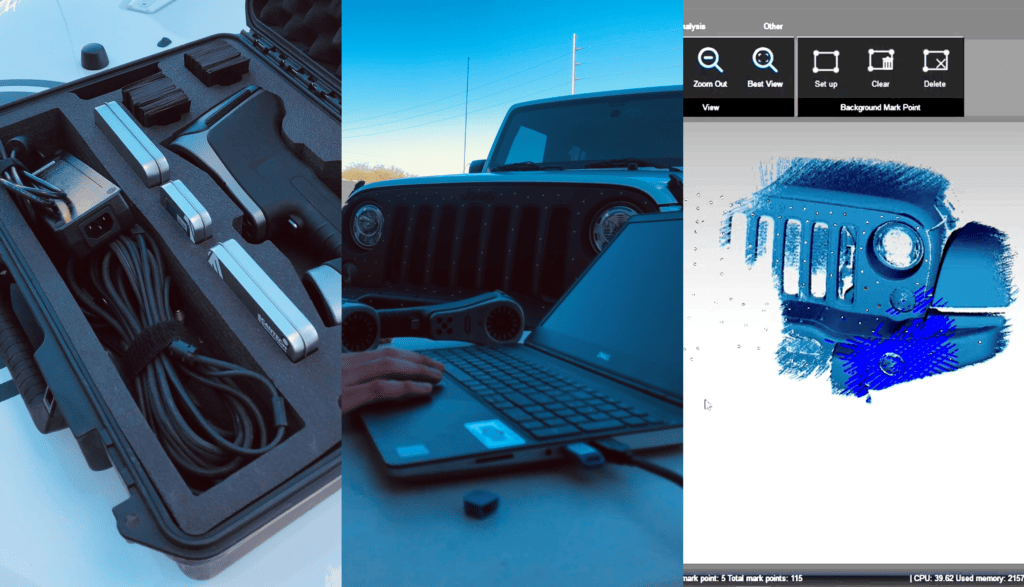

PADT has several technologies to scan and digitize physical parts. With the help of knowledgeable Engineers, PADT can help determine the best scanning technology for every scanning project based on customer needs, such as part size, color, features, desired accuracy, and desired output. Our scanning is performed at our home office in Tempe, AZ, and most of the time, parts can be easily shipped, or hand delivered, BUT what about those parts where shipping and delivery are not feasible? Parts that are too big, delicate, or confidential? Fret not, because PADT offers mobile/on-site scanning using a handheld laser scanner.

Handheld Laser Scanning

As with many scanning technologies, our handheld laser scanner is a non-destructive, non-contact technology that uses lasers to rapidly project multiple dots on the surface of the part and captures its reflection with sensors to determine the part shape and topology. Some of the items we have scanned using our handheld scanner are industrial equipment, airplane fuselage, automobiles, and appliances. As with all technologies, there are advantages and disadvantages to laser scanning.

Advantages

- Portable

- Able to scan large objects more easily

- Can scan most part colors and surfaces (such as dark and shiny surfaces) without surface/part treatment

- Can scan in low light conditions

Disadvantages

- In general, accuracy is lower than other scanning methods such as structured light scanning

- Difficulty to scan items in high light and direct sunlight conditions

- Only captures external surfaces and features

If interested in PADT’s equipment and technologies, please visit our scanning web pages or other technology pages or contact us at scan@padtinc.com

Article by Adam Dixon | Media by Josephine Holmes | Follow us on Instagram for more 3D Printing & 3D Scanning content