Part 2 of our 3D printing series where we introduce our newest technology. The Origin One is Stratasys’ golden child because of its versatility and success in short-run production. Using P3 technology (Programmable PhotoPolymerization), an evolution of DLP (digital light processing), the Origin uses photoreactive chemistry to cure liquid polymer resin while multiple sensors control light, temperature, and other conditions. Now, time to help you decide if the Origin fits your project(s) needs.

What’s Best About the Origin One?

- Wide range of high-performance materials

- Excellent surface quality that rivals injection molding

- The build volume is 7.55″ x 4.25″ x 14.5″

- The minimum feature size is 0.003″ XY / 0.006″ in Z

Do you need a large number of small parts with difficult geometries? The Origin One is a great option, especially if it can’t be supported. Do you need fine features or solid cross-sections? Look into the Origin One. If you need injection molding surface quality, also look into the Origin. If you need all of those, request the Origin. It’s a great overall go-to printer for these types of projects. The best applications for the Origin include:

- Short-run production parts

- Realistic prototypes

- Production tooling

- Elastomeric components

If you’re still confused, here are some points of when NOT to request 3D printing work on the Origin:

- Material requirements- Self-explanatory. If you need your part(s) to have specific properties, like excellent ductility or the strength to carry a ton, then the Origin is not it

- Large volume/cross sections- P3/DLP is not the right technology for big blocks of material due to warping, shrinking, etc.

- Mechanical strength- The Origin is not meant for that. You aren’t going to be able to print a trailer hitch on the Origin and expect it to work well.

Material Spotlight: ST45 Black

Advantages of ST45 black:

- Good general purpose

- Excellent strength

- ABS-like black resin

- Fast-printing

- Cost-effective

ST45 Black is our most used and recommended material for the Origin due to its properties and application versatility. Not only is ST45 great for highly detailed or textured parts, but it has high hardness and impact strength. Perfect for prototypes, patterns/molds, and mass customization. Again, a great general-purpose material. Unless you need a material with other specific properties, such as vertical burn or aerospace FST standards (Loctite 3955 FST – another Origin material), ST45 Black is the best material to request. However, the one downside of ST45 Black is that it doesn’t perform well in applications where it is exposed to water.

Time vs Cost vs Part (size/qty) Overview

Just as we did with our “Why You Should Request Work on our Neo450” blog, we will answer the burning question “How much will this cost me and how long will it take?” for the Origin One. Using ST45 Black, we will provide a rough estimate of what time vs cost looks like using an example part.

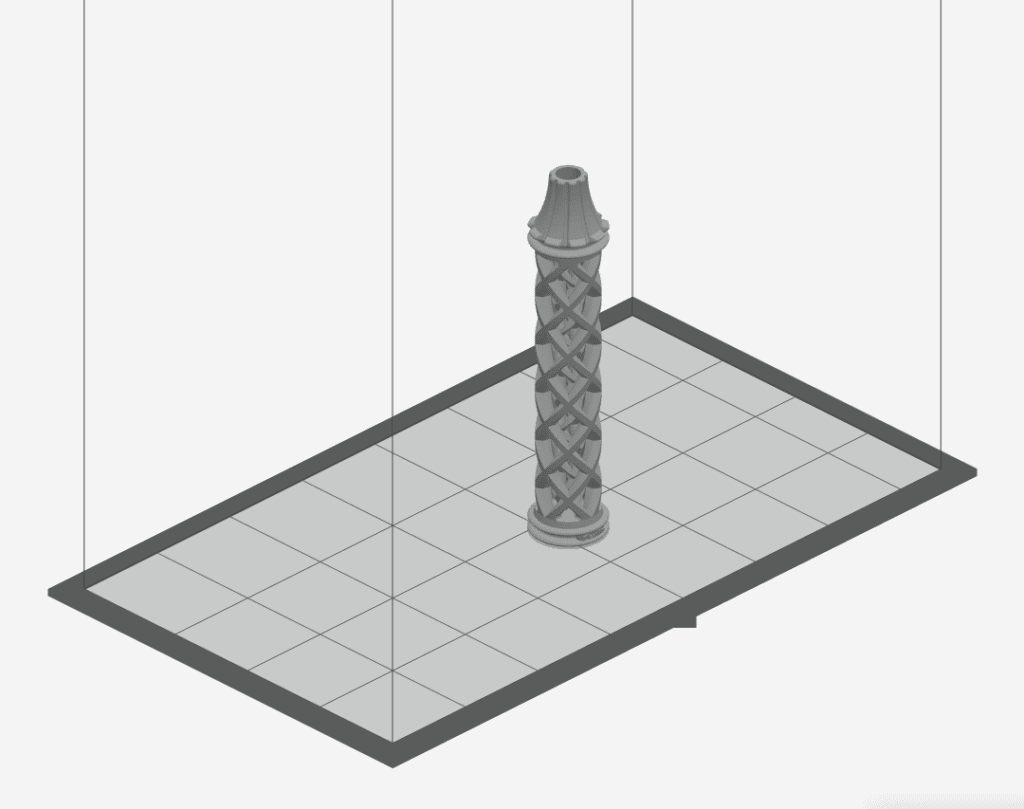

1 Part with ST45 Black

- Time= 3hr 25min

- Cost per part= $95 each

- Total Cost= $95

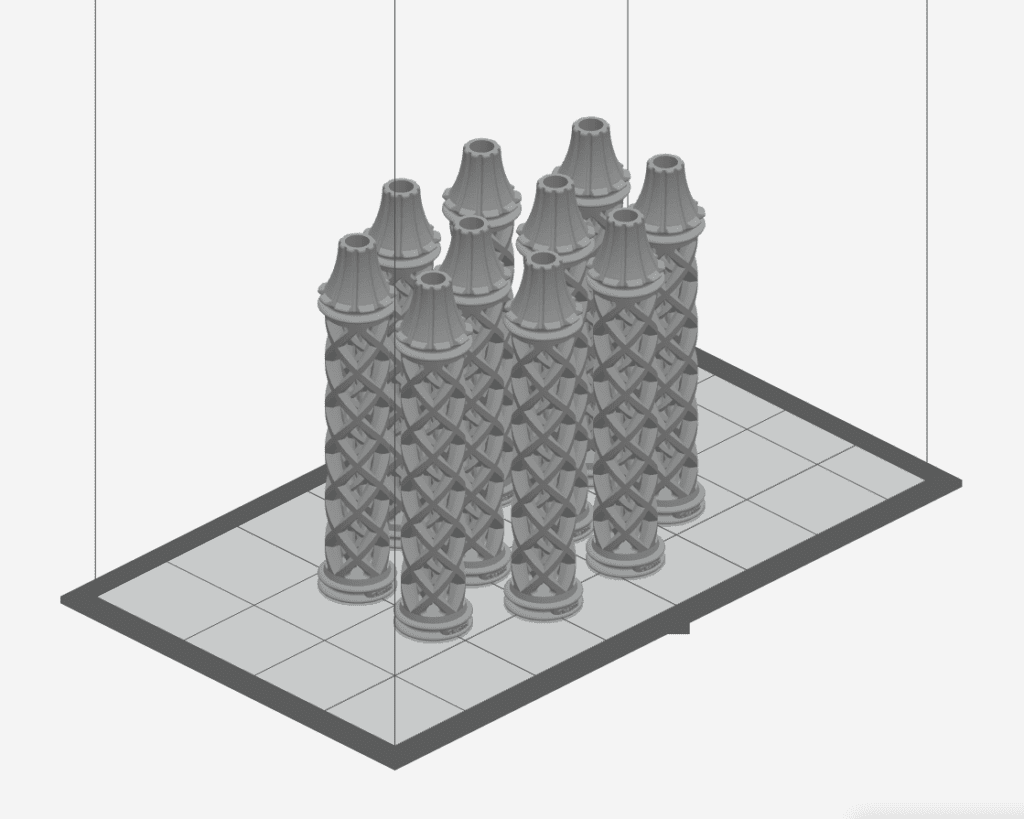

10 Parts with ST45 Black

- Time= 3hr 25min

- Cost per part= $30

- Total Cost= $300

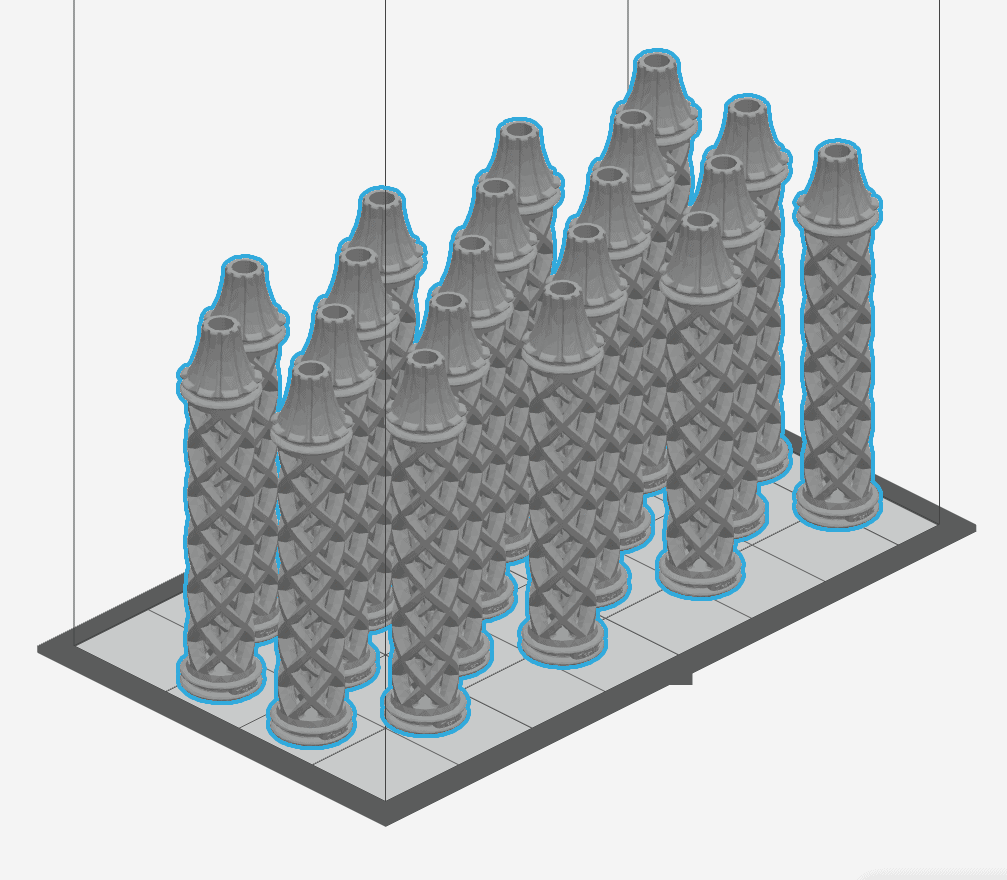

100 (4 builds with 25 each) with ST45 Black

- Time= 13hr 40min

- Cost per part= $13 each

- Total Cost= $1,300

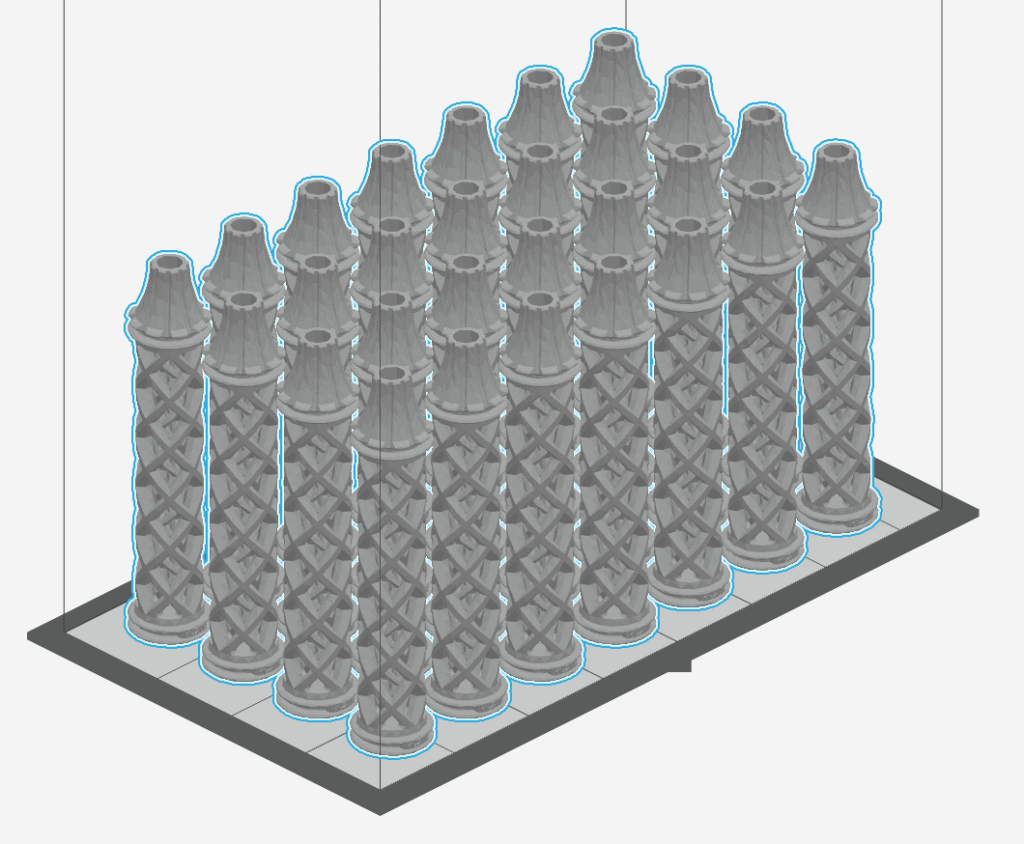

1 Filled Platform with ST45 Black

- Time= 3hr 25min

- Cost per part= $17

- Total Cost= $408

Now that you know a little more about the Origin and one of our favorite materials, we look forward to continuing this series and helping you find the right fit for your project(s)! If ST45 Black is not what you’re looking for, go to our P3 section on the website to see other material options. Lastly, as always, not every project will need the same solution based on size, qty, features, etc. If you have any more questions about if the Origin One is a great fit for your 3D printing project(s), please contact us at 3dprint@padtinc.com.

Follow us on Instagram for more 3D Printing and 3D Scanning content!

Article written by Josephine Holmes with a special thanks to Brad Palumbo.