Materials Introduction

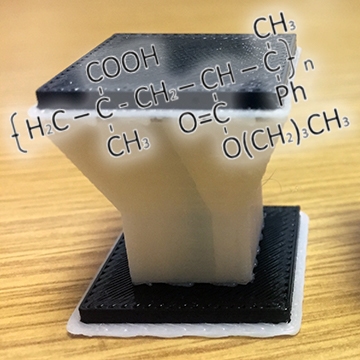

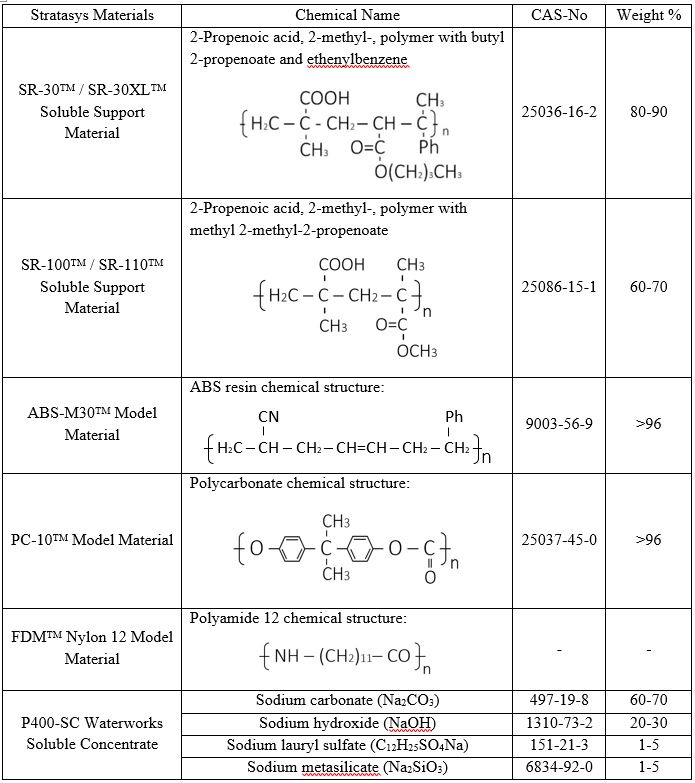

We begin by looking at the composition of the different materials involved in the table below.

How P400-SC Works for Support Materials Removal

Polymer can swell and then dissolve into water as a consequence of abundant hydrophilic groups, like carboxyl group (-COOH), ether group (-O-), hydroxyl group (-OH) and so on in its molecular structure. Theoretically, SR-30TM and SR-100TM /SR-110TM Soluble Support Materials including a carboxyl group (-COOH) in their repeat unit are likely to be water soluble. However, they also have a hydrophobic ester group (-COO-) in their repeat unit, which counteracts the efficacy of the hydrophilic group on the long carbon chain. Thus, the key to making SR-30TM and SR-100TM /SR-110TM soluble, is to somehow get rid of the ester group.

Hydrolysis of ester in pure water is a slow process even the system is heated. Both acid and alkaline conditions can catalyze and speed up the process. Under the acid condition, the hydrolysis is a reversible process until it reaches an equilibrium state, whereas alkaline conditions promote a thorough hydrolysis with a stirring and heating system.

P400-SC Waterworks contains sodium carbonate, sodium hydroxide, sodium lauryl sulfate and sodium metasilicate. The last two constituents, with 1-5 wt% respectively, are auxiliaries in the P400-SC Waterworks. The remaining two react with carboxylic acid and ester group per the following chemical reaction:

- R-COOH + NaOH = R-COO– Na+ + H2O (neutralization reaction)

- 2 R-COOH + Na2CO3 = 2 R-COO– Na+ + H2O + CO2

- R1–COO-R2 + NaOH ≜ R1-COO– Na+ + R2OH (ester hydrolysis under alkaline condition)

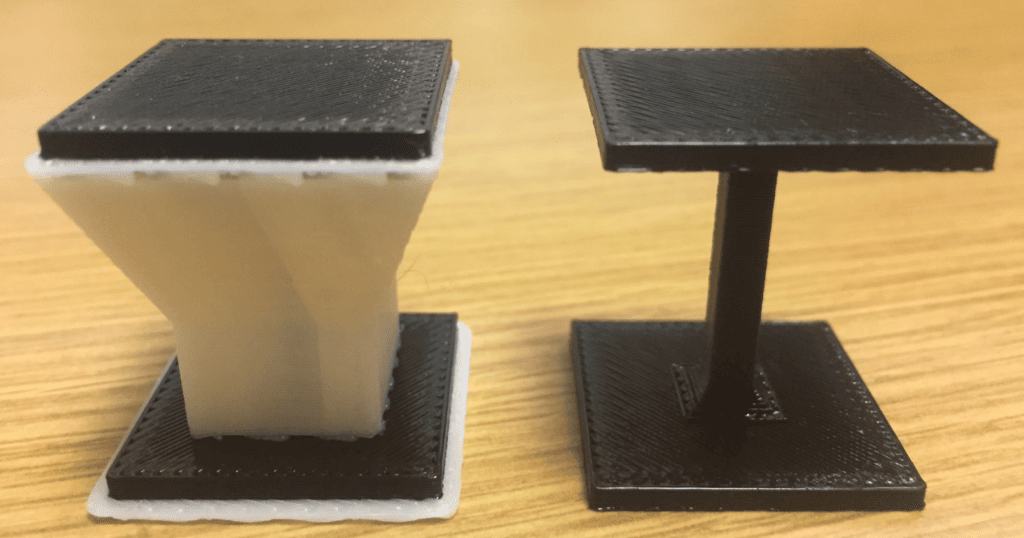

where R is the remaining carbon chain apart from carboxyl group and R1, R2 represent the two-side segments of ester group. Ester hydrolysis is the main reaction we need, which ionizes the ester group and makes it water soluble with an increased polarity. These reactions would happen when SR-30TM or SR-100TM /SR-110TM supports are dropped into a tank with P400-SC Waterworks cleaning solution inside.

From the table above, we can see that ABS-M30TM and PC-10TM don’t have hydrophilic groups, which restrains their solubility into water. Nylon is semi-crystalline polymer and difficult to dissolve into water and most organic solvent, despite the presence of the hydrophilic group acylamino (-CONH-), which still results in a nice water-absorbing ability. All these model materials are common-use engineering plastic with nice chemical resistance (depending on their functional groups), they can be safe in the cleaning solution.

The SCA tank offers an optimized environment with agitation and heating for the ester hydrolysis reaction. The tank has four preset temperature options (50 ℃, 60℃, 70℃, 85℃) for ABS-M30TM, PC-10TM, and FDMTM Nylon 12 model materials, due to their different thermal resistance. The innovative custom designed pump is key to cause the solution to effectively and efficiently dissolve and remove the support materials.

For more information on PADT’s entire line of SCA, please see http://www.supportremoval.com/