If you’ve been following Girl Gang Garage on LinkedIn or Instagram, you know there’s been a ton of progress on the Iron Maven Volvo-rebuild project since PADT’s last post in July. Back then, most of the work had focused on gutting the 1961 Volvo PV544 body and interior, and PADT was able to capture much of the sheet metal shape and dimensions with its GOM Tscan Hawk 3D scanner. We also started brainstorming various 3D printed parts to enable new component designs produced on Stratasys 3D printers.

Since then, Bogi Lateiner, co-owner of Girl Gang Garage (and TV host of Motortrend’s All Girls Garage and Garage Squad), co-owner Shawnda Williams, and a rotating team of volunteer women have turned their efforts to disassembling the second vehicle: the new 2019 Volvo S60 T8 Polestar Engineered sedan (donated by corporate sponsor Volvo) and merging its chassis with the PV544 body.

Sounds simple, sort of? It might be if it weren’t for the facts that:

- a) the wheelbase (front-tire center to rear-tire center) of the two cars differs: the PV544 clocks in at 102.5 inches but the S60 is quite a bit longer, at 113 inches. Also,

- b) the track width (axle length) differs – this time the PV544 is about 12 inches narrower at the front (51 inches versus 63 inches), which means the Girl Gang team needs to expand both of the front fenders by half that amount to accommodate everything in the engine compartment. And, lastly and conversely,

- c) the S60 dashboard is so wide that it needs to be reconfigured from 56 inches down to about 50 inches or less, to fit the interior dimensions.

Growing Fenders, Redesigning a Grill

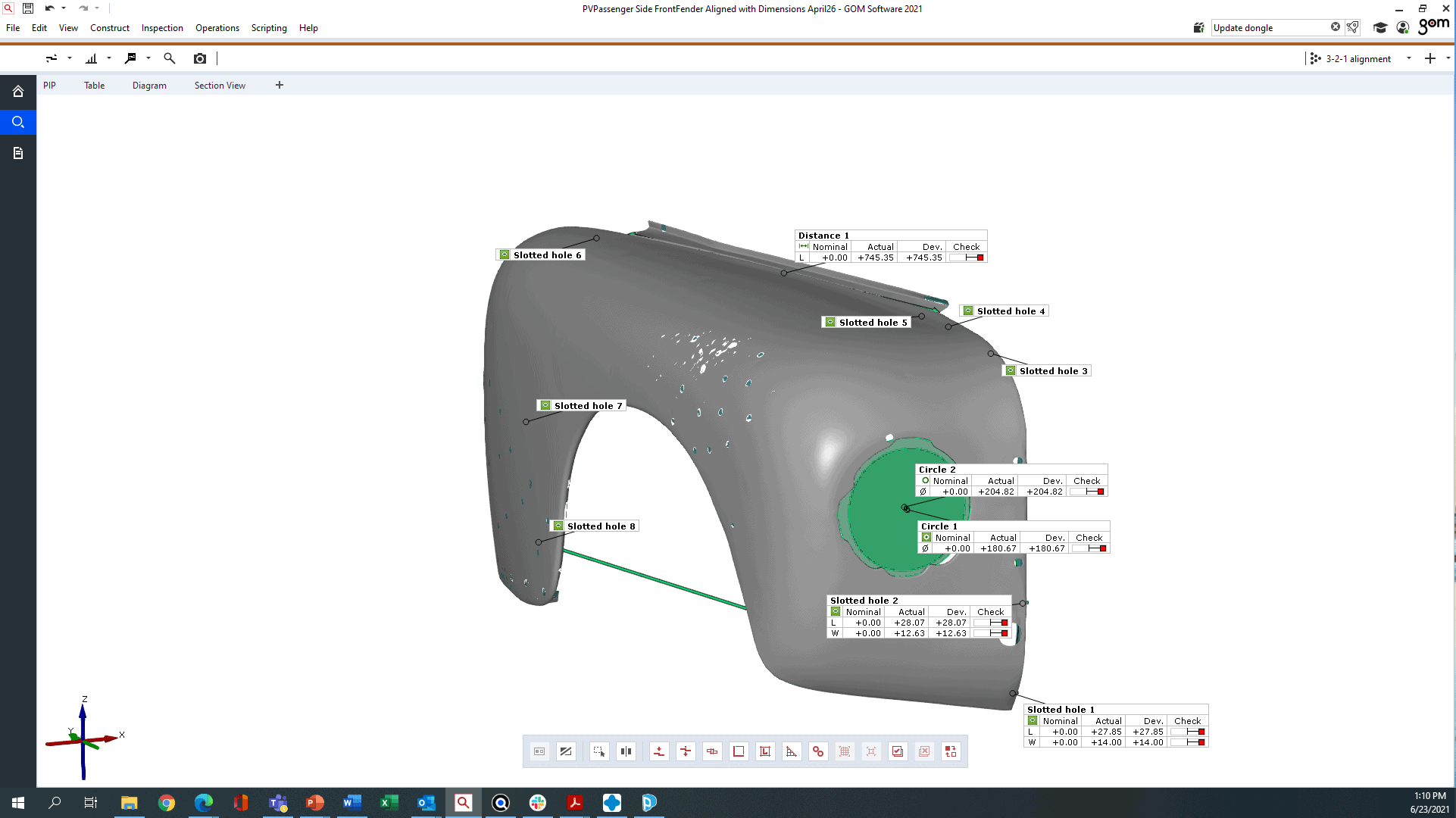

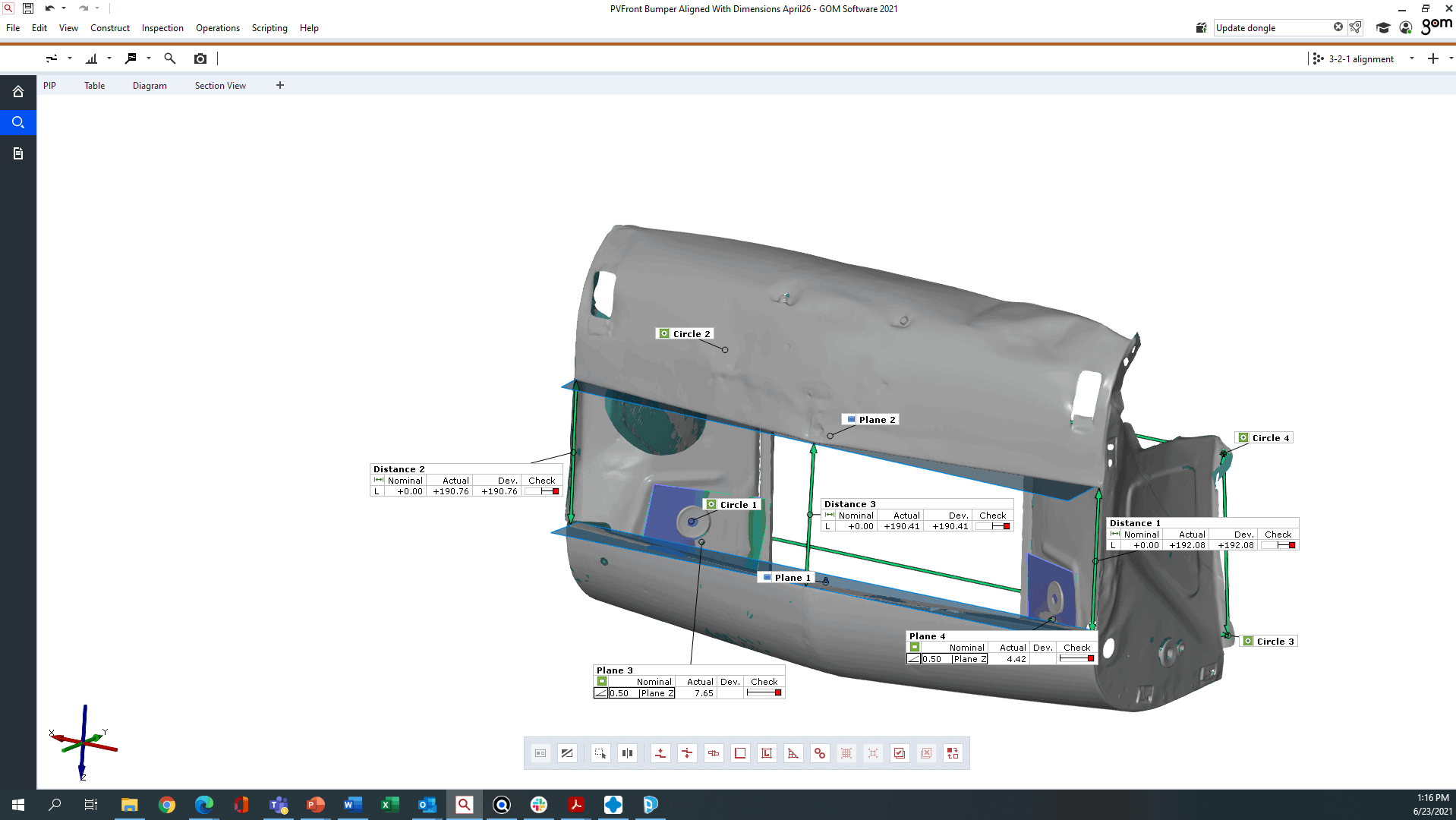

The old-school approach to reconstructing the front bumper-grill section and fenders would involve cutting the original sheet metal, shaping new metal splices by eye and tape-measure, and welding everything together with skilled handwork. This time, although the first and last steps still apply, that project becomes a much more precise, and predictable, task thanks to the digital workflow of 3D scanning -> data processing -> CAD design. These steps are now underway and will set the stage for a cool new grill and fenders that will act big but fool the eye just a bit to keep the overall lines intact.

It’s pretty clear that this front-end has seen better days, so the analysis and measurements of the existing surface needed to be carefully analyzed. Donated expertise for this task came from Chris Strong and Hayati Dirim of Rapid Scan 3D, who mapped the scanned mesh onto planes and surfaces that define the current grill-mount opening.

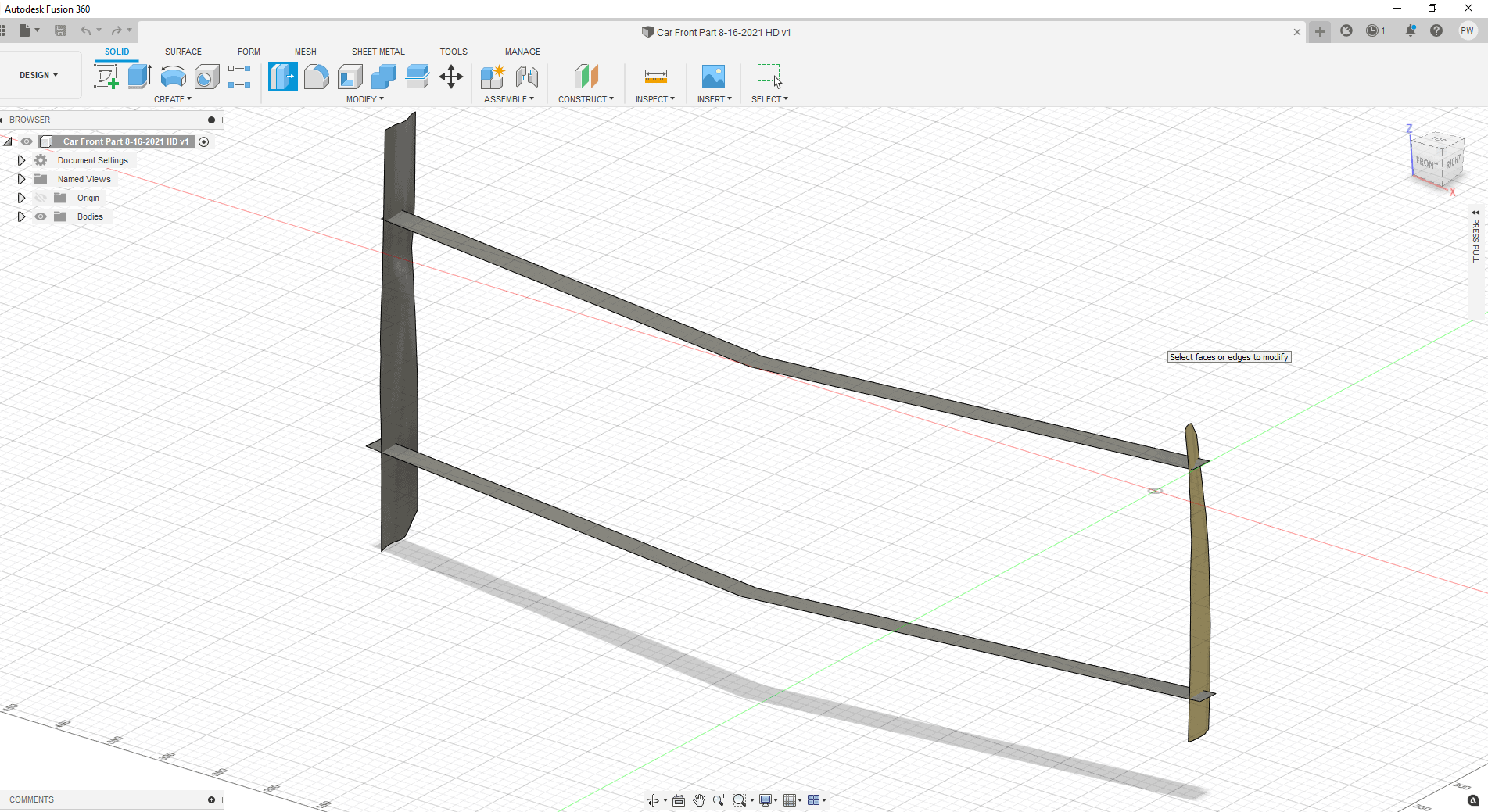

This information has been handed off to the CAD support team. Working hand-in-hand with the Girl Gang Garage experts, the team is using Fusion 360 CAD software, donated from Iron Maven sponsor Autodesk, to analyze these defining surfaces and design a new grill in CAD, which we expect will be 3D printed and painted to match the updated (not yet announced) body color from sponsor BASF.

Knowing both the fender and grill/frame exact dimensions also supports the team in defining the connections and shape of the widened fenders.

Dashboard Surgery

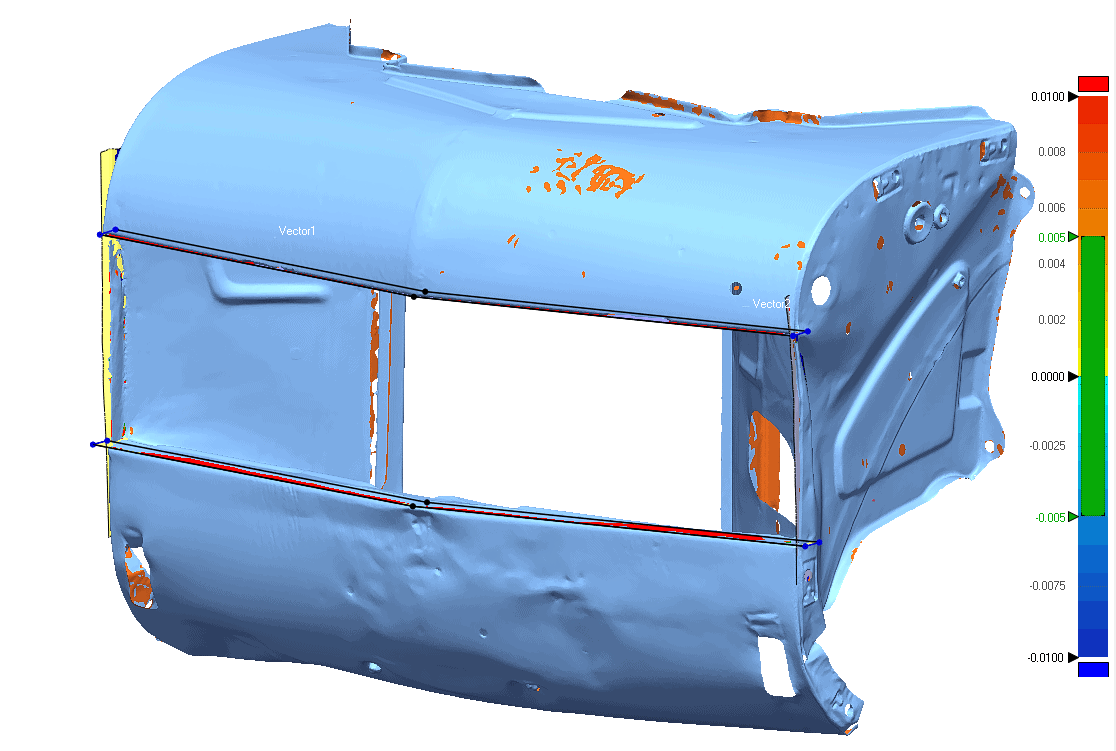

The brand-new 2019 Volvo S60 T8 Polestar Engineered sedan was almost too cool to cut up – but Girl Gang Garage knew that something even better would emerge in the end. Before the roof was cut off (see the video on LinkedIn), the work timeline required removing the dashboard with all its electronic components.

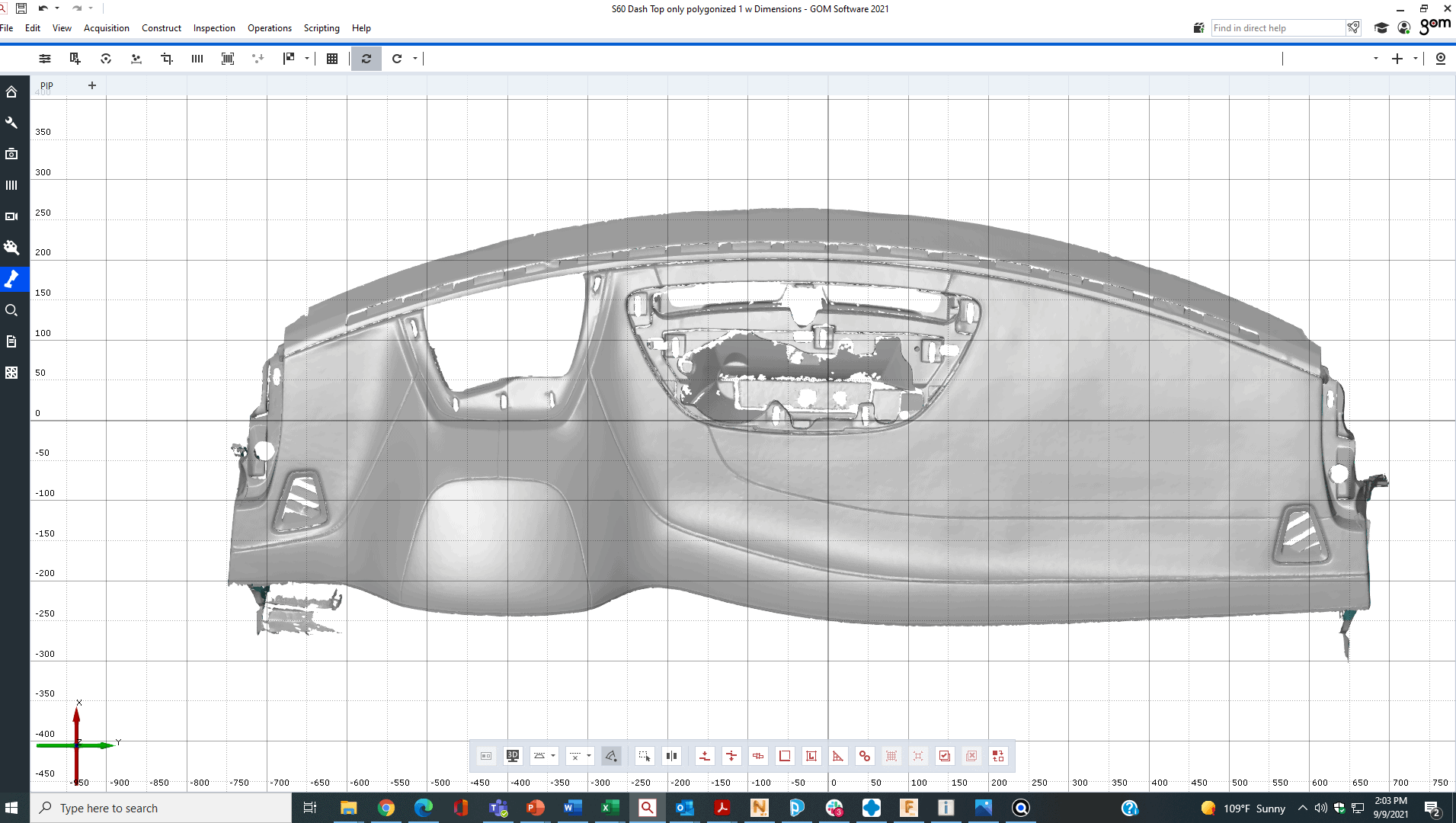

Here’s the extracted S60 dashboard, viewed from the bottom and front:

And the frame behind it:

And here are the existing red PV544 dash and the black S60 version side by side (the dots are the reflective targets used with the 3D laser scanner). The S60 configuration needs to fit in the original PV544 space. To compress this at least five inches, the glove-box probably has to go.

Once again, the team is turning to scan data, and that analysis is in process.

Stay Tuned

Due to the scheduling and travel challenges presented by the ever-shifting COVID scene, Girl Gang Garage has decided to complete the Iron Maven for presentation at the 2022 SEMA Show (highlighting automotive specialty products). This also allows more time for 3D printing the new components which are coming off the Stratasys F370 printer. PADT will be documenting updates and sharing cool photos of this one-of-a-kind project in the months to come.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing products and services. For more information on GOM 3D scanners and Stratasys printers and materials, contact us at info@padtinc.com.