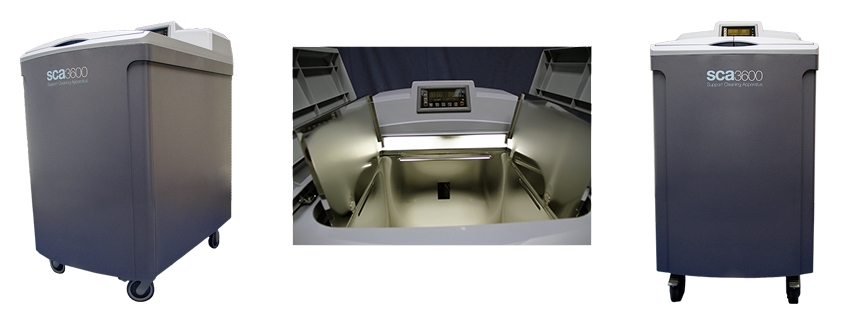

Building on the worldwide success of previous products in the family, PADT has just released the new SCA 3600, a large capacity cleaning system for removing the support material from Stratasys FDM parts. This new system adds capacity and capability over the existing benchtop SCA-1200HT System.

A copy of the press release is below.

At the same time, we are also launching a new website for support removal: www.padtinc.com/supportremoval.

Editor’s Note (3/23/2022): This site has been removed and our SCA product line was spun out of PADT as Oryx Additive. Please visit www.oryxadditive.com to learn more about all of our new post-processing solutions.

The SCA 3600 can dissolve support from all the SST-compatible materials you use – ABS, PC, and nylon. A “no heat” option provides agitation at room temperature for the removal of Polyjet SUP706 material as well. The SCA 3600’s versatility and efficient cleaning performance are built on the success of earlier models with all the features you have come to expect, in a larger and more capable model.

Since the launch of the original SCA-1200 in 2008, PADT has successfully manufactured and supported the SCA family of products for users worldwide. Common requests from desktop SCA users were for a larger system for bigger parts, the ability to clean many parts at the same time, and the option to remove supports from PolyJet parts. The SCA 3600 is the answer: Faster, larger, and more capable.

SCA 3600 Key Features are:

- Removes soluble support from ABS, PC, and nylon 3D printed FDM parts

- Removes soluble support from PolyJet 3D Printed parts

- User-selectable temperature presets at 50, 60, 70, and 85°C and “No Heat” for PolyJet

- User-controlled timer

- Uses cleaning solutions from Stratasys

- Unique spray nozzle optimizes flow coverage

- 230 VAC +/- 10%, 15A

- Whisper-quiet operation

- Includes rolling cart for easy movement, filling, and draining.

- Capacity: 27 gal / 102 L

- Size: 42.8″ x 22.8″ x 36.5″/ 1,086 x 578 x 927 mm

- 16” x 16” x 14” / 406 x 406 x 356 mm removable large parts basket

- Integral hinged lid and small part basket

- Stainless steel tub and basket

- Over temperature and water level alarms

- Automatic halt of operation with alarms

- Field replaceable sub-assemblies

- Regulatory Compliance: CE/cTUVus/RoHS/WEEE

You can download our new brochure for both systems:

SCA 3600 Spec Sheet:

SCA-1200HT Spec Sheet:

If you are interested in learning more or adding an SCA 3600 to your additive manufacturing lab, contact your Stratasys reseller.

Official copies of the press release can be found in HTML and PDF.

Press Release:

New 3D Printing Support Cleaning Apparatus Features Large Capacity for Stratasys FDM Systems

Offered Worldwide, the SCA 3600 is Big Enough to Handle Large 3D Printed Parts, Effortlessly Dissolving Support Material

TEMPE, Ariz., November 17, 2016 – Phoenix Analysis & Design Technologies, Inc. (PADT), the Southwest’s largest provider of simulation, product development, and rapid prototyping services and products, today introduced its new SCA3600 3D Printing Support Cleaning Apparatus (SCA). The systems are sold exclusively by Stratasys, Ltd. (SSYS) for use with its FORTUS line of 3D Printers. The hands-free support removal technology is a huge advantage to people who use Fused Deposition Modeling (FDM) systems for their 3D Printing.

“With more than 10,000 of our benchtop SCA units in the field, we gathered a wealth of knowledge on performance and reliability,” said Rey Chu, Co-owner and Principal of PADT. “We used that information to design and manufacture a system that cleans larger parts, or multiple small parts, while keeping the speed, easy maintenance and great user experience of the benchtop system.”

A powerful upgrade over PADT’s successful SCA-1200HT and SCA-1200 support removal products that have been in use around the world since 2008, the SCA 3600 features a simpler, more user-friendly design. The new versatile SCA offers temperature choices of 50, 60, 70 and 80 degrees Celsius, as well as no-heat, that readily cleans supports from all SST compatible materials – ABS, PC and Nylon. The SCA 3600 also features a large 16” x 16” x 14” parts basket, 3400 watts of heating for faster warm-up and a wheeled cart design for mobility.

The advantages of the system were highlighted by Sanja Wallace, Sr. Director of Product Marketing and Management at Stratasys, Ltd. when she commented, “the addition of the SCA 3600 as an accessory to our very successful FORTUS systems simplifies the support removal process with increased speed and capacity for multiple large parts.”

Once parts are printed, users simply remove them from their Stratasys FDM system, place them in the SCA 3600, set a cleaning cycle time and temperature, and then walk away. The device gently agitates the 3D printed parts in the heated cleaning solution, effortlessly dissolving away all of the support material. This process is more efficient and user friendly than those of other additive manufacturing systems using messy powders or support material that must be manually removed.

More information on the systems available at www.padtinc.com/supportremoval. Those interested in acquiring an SCA 3600 should contact their local Stratasys reseller.

About Phoenix Analysis and Design Technologies

Phoenix Analysis and Design Technologies, Inc. (PADT) is an engineering product and services company that focuses on helping customers who develop physical products by providing Numerical Simulation, Product Development, and Rapid Prototyping solutions. PADT’s worldwide reputation for technical excellence and experienced staff is based on its proven record of building long term win-win partnerships with vendors and customers. Since its establishment in 1994, companies have relied on PADT because “We Make Innovation Work.” With over 80 employees, PADT services customers from its headquarters at the Arizona State University Research Park in Tempe, Arizona, and from offices in Torrance, California, Littleton, Colorado, Albuquerque, New Mexico, and Murray, Utah, as well as through staff members located around the country. More information on PADT can be found at http://www.PADTINC.com.

###

| Media Contact Alec Robertson TechTHiNQ on behalf of PADT 585-281-6399 alec.robertson@techthinq.com |

PADT Contact Eric Miller PADT, Inc. Principal & Co-Owner 480.813.4884 eric.miller@padtinc.com |