PADT is currently partnering with Arizona State University’s 3DXResearch group on exploring bio-inspired geometries for 3D Printing. As part of that effort, one of our engineers involved in the project, Alex Grishin, PhD, was a co-author on several papers that have been published during this project.

Below is a brief summary from Alex of each article, along with links.

An Examination of the Low Strain Rate Sensitivity of Additively Manufactured Polymer, Composite and Metallic Honeycomb Structures

PADT participated in the research with the above title recently published in the open-access online journal MDPI ( https://www.mdpi.com/1996-1944/12/20/3455/htm ). This work was funded by the America Makes Program under a project titled “A Non-Empirical Predictive Model for Additively Manufactured Lattice Structures” and is based on research sponsored by the Air Force Research Laboratory under agreement number FA8650-12-2-7230.

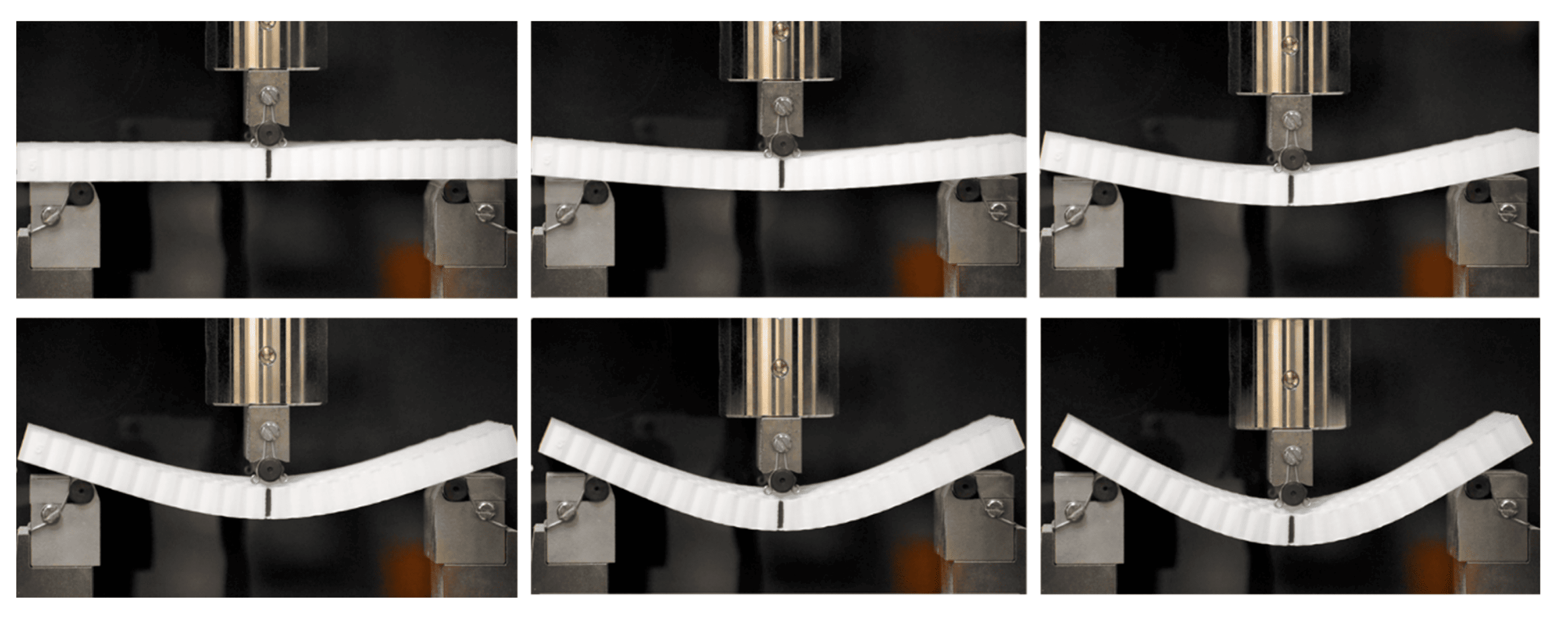

Current ASU professor and former PADT employee Dhruv Bhate was the Lead Investigator and wrote the original proposal. Dhruv’s research interests involve bio-inspired design (the study of structures found in nature to help inform human design efforts) and additive manufacturing. Dhruv is particularly interested in the bulk properties of various lattice arrangements. While investigating the highly nonlinear force-deflection response of various additively manufactured honeycomb specimens under compression, Dhruv discovered that polymer and composite honeycombs showed extreme sensitivity to strain rates –showing peak responses substantially higher than theory predicts at various (low) strain rates. This paper explores and quantifies this behavior.

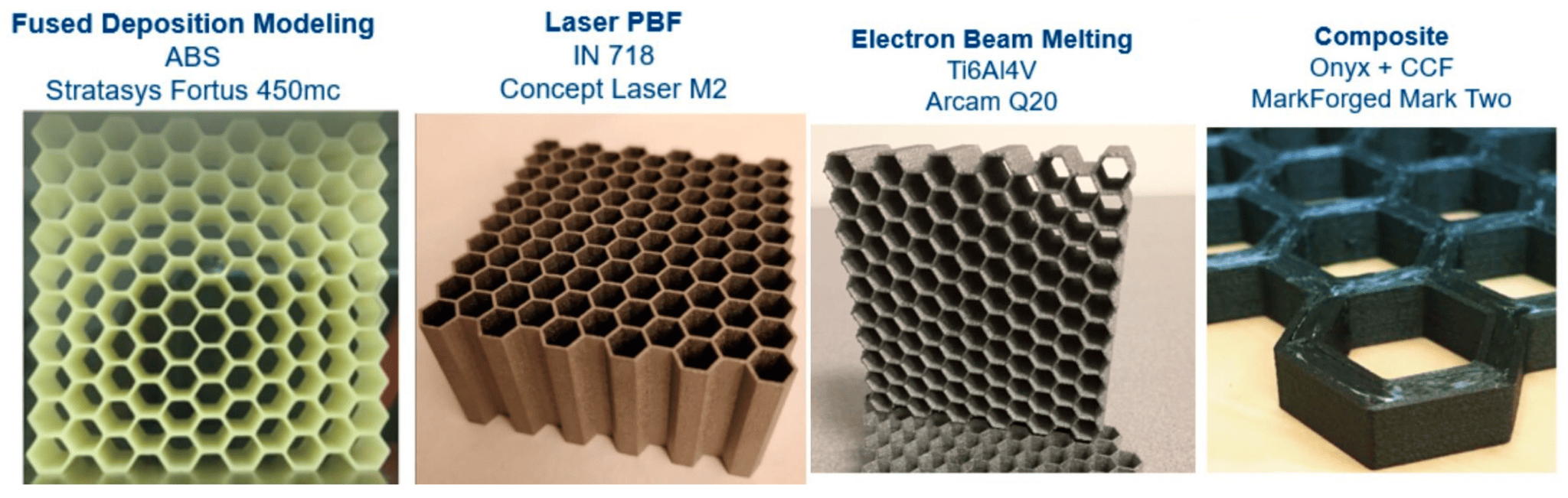

The paper investigates hexagonal honeycomb structures manufactured with four different additive manufacturing processes: one polymer (fused deposition modeling, or material extrusion with ABS), one composite (nylon and continuous carbon fiber extrusion) and two metallic (laser powder bed fusion of Inconel 718 and electron beam melting of Ti6Al4V). The strain rate sensitivities of the effective elastic moduli, and the peak loads for all four processes were compared. Results show significant sensitivity to strain rate in the polymer and composite process for both these metrics, and mild sensitivity for the metallic honeycombs for the peak load.

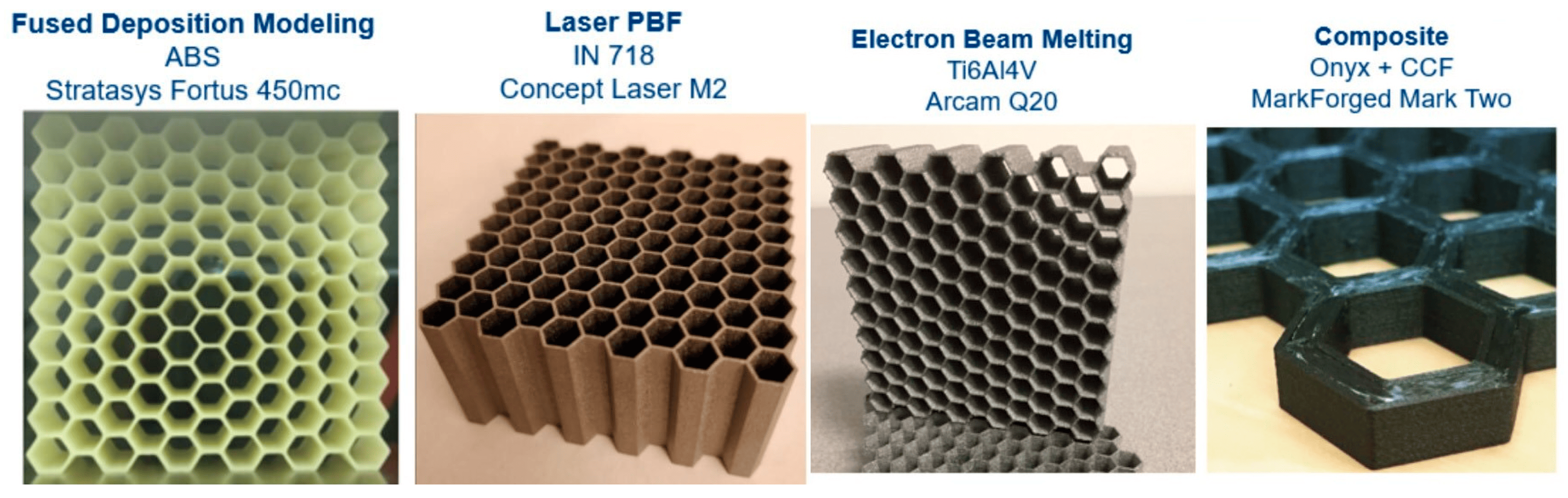

PADT contributed to this research by providing ANSYS simulations of these structures assuming viscoplastic material properties derived from solid dog-bone test specimens. PADT’s simulations helped provide Dhruv with a proposed mechanism to explain why INSTRON compression tests of the honeycomb structures showed higher peak responses (corresponding to classical ultimate stress) for these specimens than the solid specimens.

Bioinspired Honeycomb Core Design: An Experimental Study of the Role of Corner Radius, Coping and Interface

PADT participated in the NASA-funded research with the above title recently published in the open-access online journal MDPI (https://www.mdpi.com/2313-7673/5/4/59/htm ). This work was guided by former PADT engineer and current ASU Associate Professor Dhruv Bhate. Professor Bhate’s primary research interests are Bio-Inspired Design and Additive Manufacturing. It was only natural that he would secure a grant for this research from NASA’s Periodic Table of Life ( PeTaL) project. To quote from the website, “the primary objective…is to expand the domain of inquiry for human processes that seek to model those that are, were or could be found in nature…”

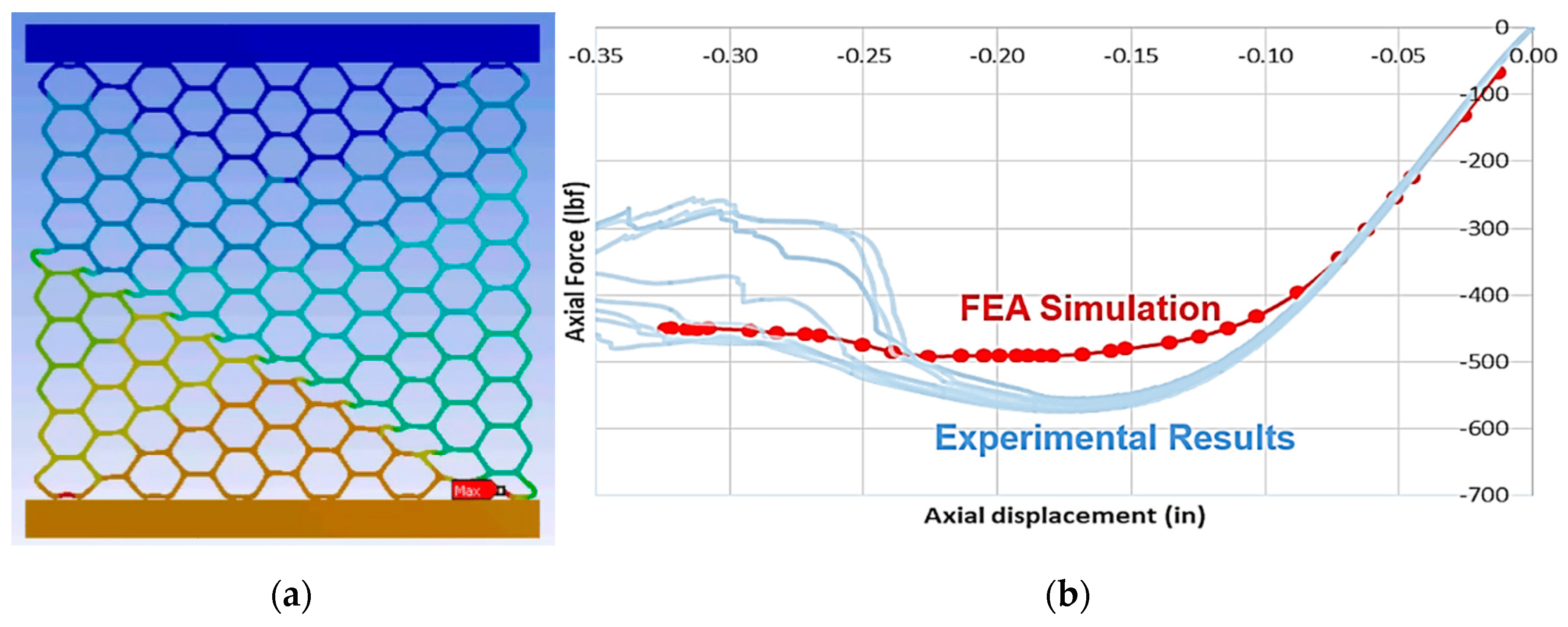

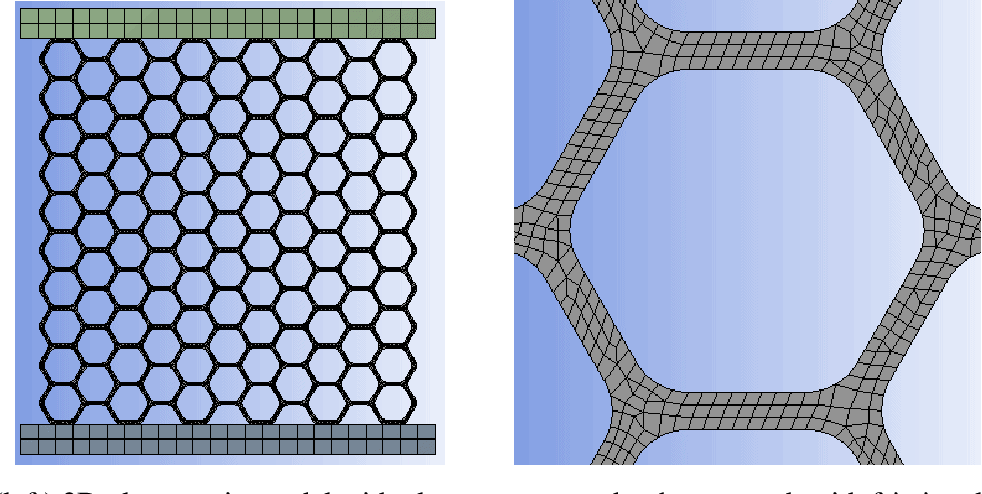

This paper focuses on the morphology of bee honeycombs found in nature –the goal being to identify key characteristics of their structure, which might inform structural performance in man-made designs incorporating similar lattice structures. To this end, the paper identifies three such characteristics: The honeycomb cell corner radius, the cell wall “coping” (a localized thickening of the cell wall at the mouth of each cell seen in a lateral cross-section), and the cell array “interface” (a zigzag pattern seen at the interface of two opposing, or “stacked” arrays).

Most of this work involved material testing and measuring dozens of natural honeycombs (most coming from various museums of natural history found in the United States) at ASU’s state-of-the-art facilities. PADT contributed substantially by verifying and guiding tests with simulation using the ANSYS suite of software.

A Comparison of Modeling Methods for Predicting the Elastic-Plastic Response of Additively Manufactured Honeycomb Structures

PADT participated in this research found in the reviewed article published in Proceedings of the 29th Annual International Solid Freeform Fabrication Symposium – An Additive Manufacturing Conference.

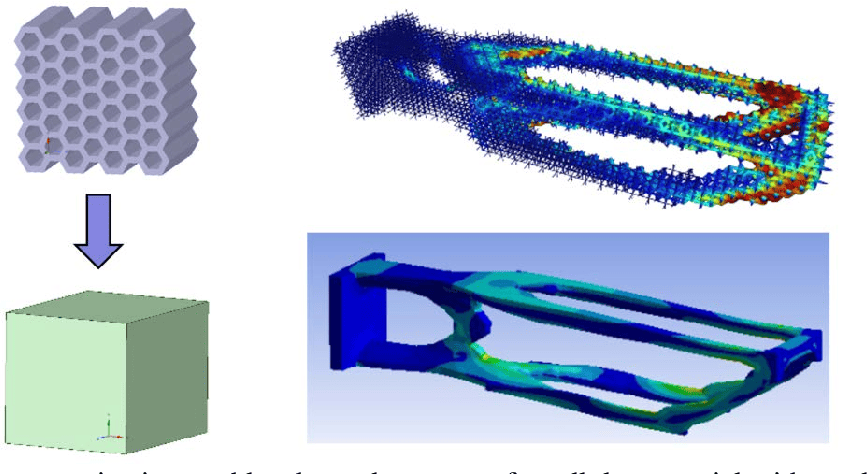

The lead investigator was current ASU professor and former PADT employee Dhruv Bhate, whose research interests involve Bio-Inspired Design (the study of natural structures to help inform human design processes) and Additive Manufacturing. In this research, Dhruv investigates discrepancies between published (bulk) material properties for the Fused Deposition Modeling (FDM) of ABS honeycomb structures. The discrepancies arise as substantial differences between published material properties, such as Young’s Modulus and yield stress, and those determined experimentally from FDM dog-bone specimens of the same material (which he refers to as “member” properties).

PADT’s role in this research was crucial for demonstrating that the differences in base material characterization are greatly exacerbated in nonlinear compression simulations of the ABS honeycomb structures. PADT used both the manufacturer’s published properties, and the dog-bone data to show substantial differences in peak stress under the two assumptions.