PRODUCTS

3D printers built for production.

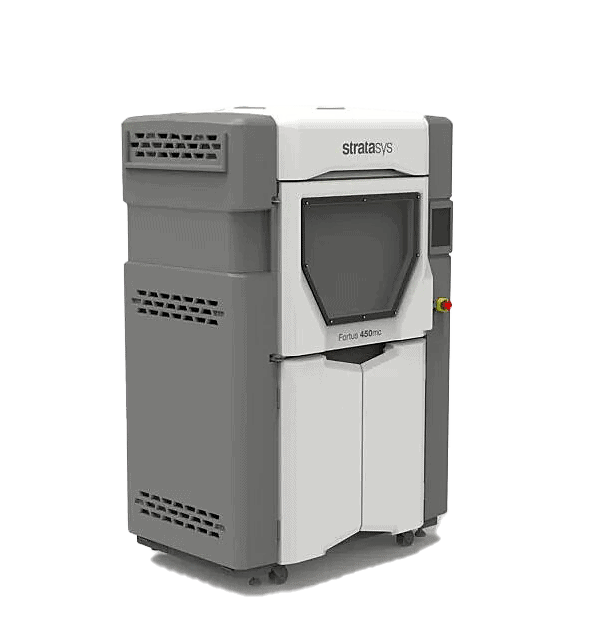

“The Fortus 450mc builds parts in the materials you’re familiar with, but with the advanced complexity and high requirements needed for today’s manufacturers. With easy-to-use interfaces and software controls, the Fortus printing systems make it easy to produce complex parts more efficiently and effectively.

For demanding applications, rely on the Fortus 450mc for high-performance materials such as FDM Nylon 12CF (carbon fiber) , ULTEM resins and ST-130 soluble material for sacrificial composite tooling.”

“The Fortus 450mc builds parts in the materials you’re familiar with, but with the advanced complexity and high requirements needed for today’s manufacturers. With easy-to-use interfaces and software controls, the Fortus printing systems make it easy to produce complex parts more efficiently and effectively.

For demanding applications, rely on the Fortus 450mc for high-performance materials such as FDM Nylon 12CF (carbon fiber) , ULTEM resins and ST-130 soluble material for sacrificial composite tooling.”

| Build Envelope | 16 x 14 x 16 in. (406 x 355 x 406 mm) |

|---|---|

| System Size/Weight | 50 x 35.5 x 76.5 in. (1,270 x 901.7 x 1,984 mm) 1,325 lbs (601 kg) |

| Network Connectivity | 10/100 base T connection. Ethernet protocol |

| Software | Insight™: Insight software prepares 3D digital part files (output as an STL) to be manufactured on an FDM 3D printer by automatically slicing and generating support structures and material extrusion paths in one push of a button. If necessary, users can override Insight’s defaults to manually edit parameters that control the look, strength and precision of parts as well as the time, throughput, expense and efficiency of the FDM process. Control Center™: Control Center is the software that communicates between the user workstation(s) and the FDM system(s), managing jobs and monitoring the production status of FDM systems. This software application provides the control to maximize efficiency, throughput and utilization while minimizing response time. Control Center is included with Insight software. GrabCAD Print: GrabCAD Print simplifies the traditional 3D print preparation workflow and provides intelligence around printer usage so your team can get quality prints, faster. Print directly from CAD, organize print queues, monitor material levels and work with detailed views of your model. The tray and slice preview feature supports adjustments before going to print. Red Hat® Enterprise Linux®: Enables STIG compliance required by U.S. government agencies via Stratasys ProtectAM™ technology. |

| Operating Conditions | Limited attendance for job start and stop required. |

| Power Requirements | 208VAC 3 phase, 50/60 Hz, consumes 18 Amps |

| Regulatory Compliance | CE, cTUVus, RCM, EAC, FCC Part B |

| Part Accuracy | Parts are produced within an accuracy of +/- .005 in. (.127 mm) or +/- .0015 in./in. (.0015 mm/mm), whichever is greater. |

| Installation Requirements | v |

Max Materials printed simultaneously: 14

| *Layer Thickness: | From 0.330 mm(0.013 in.) to 0.127 mm (0.005 in.) |

|---|---|

| *Support Structure: | Soluble, Breakaway |

| *Available Colors: | Black, Dark Gray. Light Gray, White, Ivory, Dark Blue, Green, Yellow, Orange, Red |