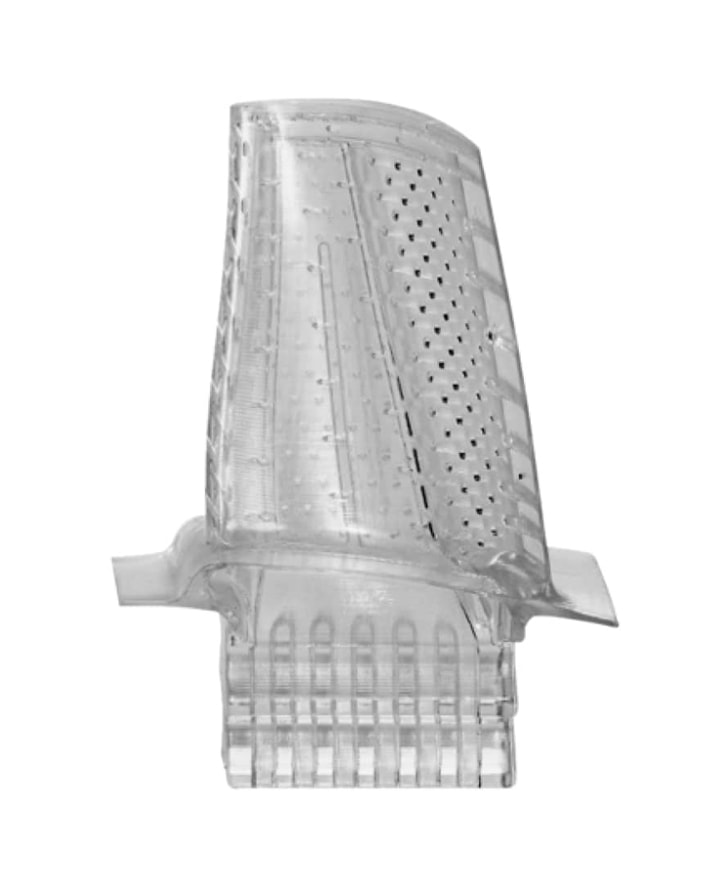

Stereolithography (SLA) builds parts using a tank of liquid photopolymer where a precise UV laser selectively cures and solidifies the photopolymer resin in thin layers.

*Accuracy/tolerance may vary with part geometry, dimensions, and build orientation

*Numbers are based on published Stratasys data

Material color limited by selection: White, Black and Clear

Our team of experts is here to help. Please provide as much information as possible. We will reach out for additional information, if needed, and then generate a quote. If you have any questions, give us a call at 480.813.4884 or drop us an email at 3dprint@padtinc.com.

If the form is not displaying correctly, please use this page.