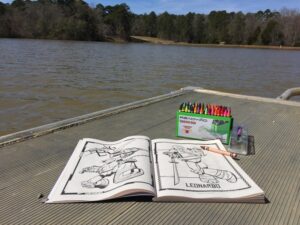

As a parent I know that crayon management has always been a problem in our family, especially when we travel. We could have used the ReadyXO – a simple container that cleverly uses the lid to provide stability so it doesn’t tip over. Now is your chance to control your crayons and help fund a great entrepreneur, and PADT customer, through KickStarter.

This is a great idea, a simple solution, by an individual entrepreneur who applied good problem solving and engineering to develop a solution to something that most of us have dealt with when we were kids or as parents.

Check out the details at:

[NOTE: Sadly this product never got funded, so this link is no longer valid 🙁 (6/17/2022)]

www.kickstarter.com/projects/996897358/readyxo-crayon-box

Scroll down and read “The Story.” If you didn’t want to get one out of simple necessity, when you hear about the inventor’s journey you will want to back this enterprise immediately.

One of the best parts of working at PADT is helping our customers make their ideas work. From a new valve actuator on the International Space Station to clever gadgets. Sometimes we see some great ideas from individual inventors that solve a day-to-day problem with a simple and elegant solution and get to help out just a little on their journey. This is a fantastic example of that.

Help us help them by pre-ordering your ReadyXO Crayon Box on KickStarter and spread the word through social media.