With three decades of experience, the PADT team is the perfect partner for acquiring, deploying, and supporting your 3D Printing solutions

Stratasys Materials & Consumables

Implementing Additive in a New Direction

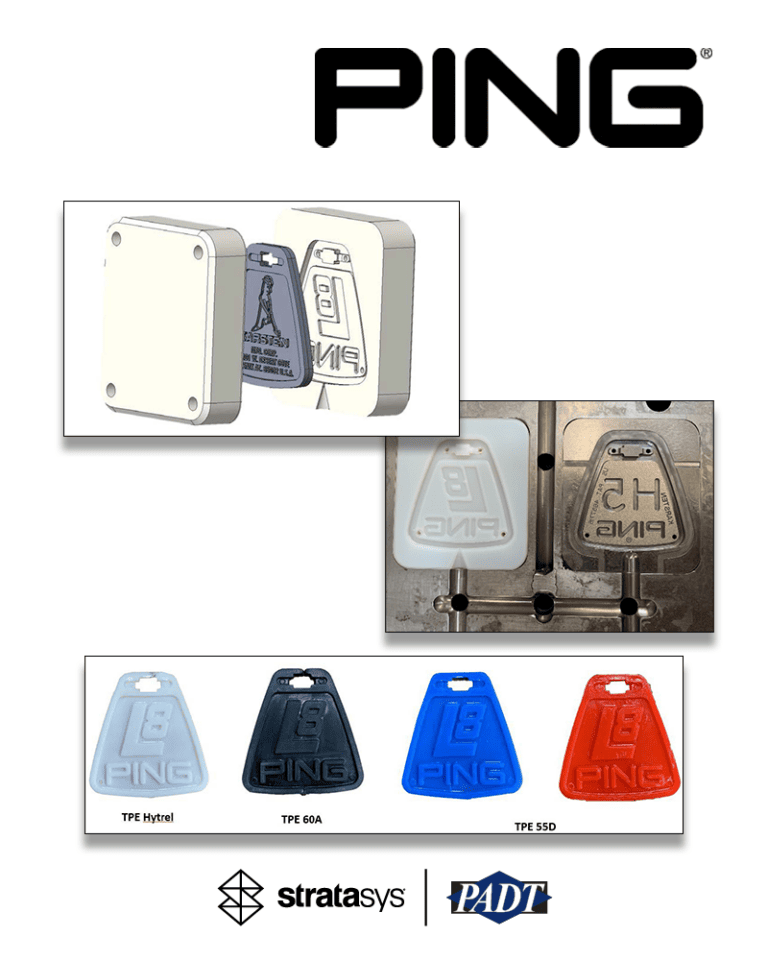

Always on the lookout for new ways to optimize their workflow, PING recently set out to find new technologies that could be used to further speed up and reduce the costs of its development processes. Additive manufacturing has been used at PING for over 20 years in various capacities, so investigating developments in that field was a logical next step. The company set out to pinpoint specific stages in its process through which implementation would benefit the entire manufacturing organization.

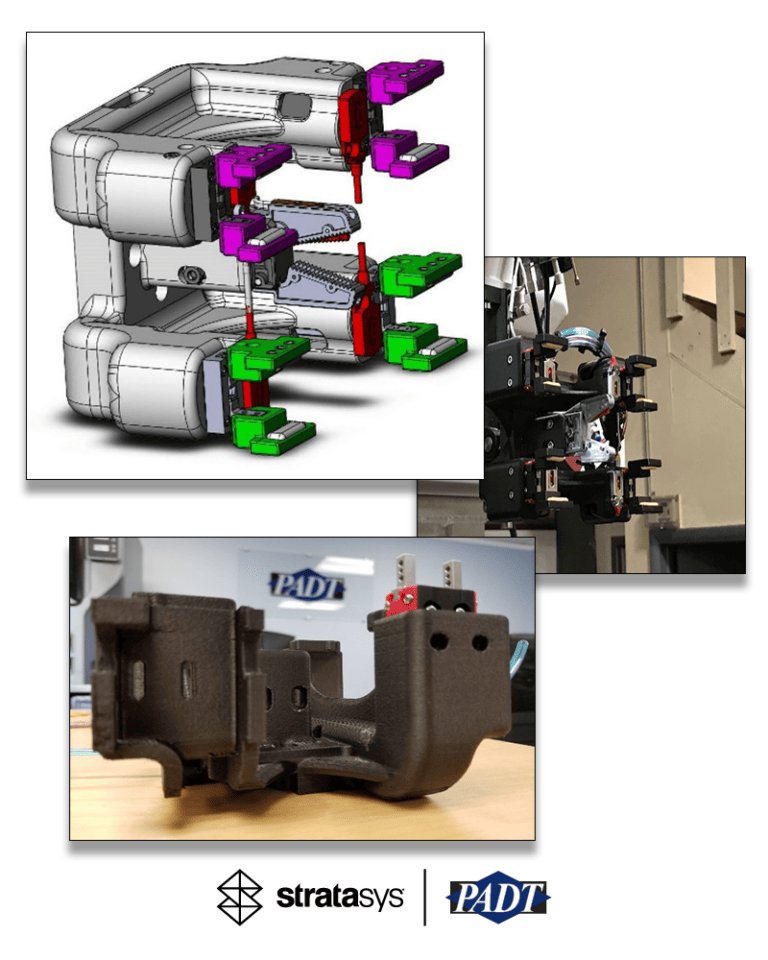

Robotics and Their Role in the Factory of the Future

In the factory of the future, automation is king. Manufacturers can drastically reduce lead times, reduce labor costs, and increase overall efficiency through the use of robotics at several stages in their workflow. These machines serve a variety of functions on the factory floor, including everything from gripping and positioning parts to welding and painting assemblies in the later stages of the manufacturing process. While each function serves a unique purpose specific to the task it will perform, they all utilize an essential component known as End-of-Arm tooling (EOAT).

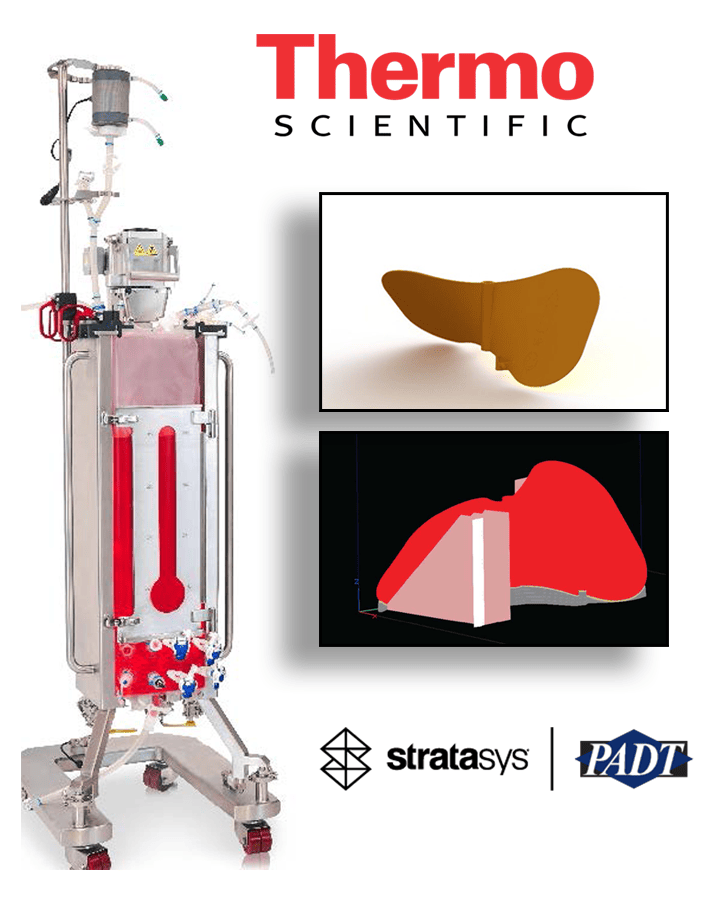

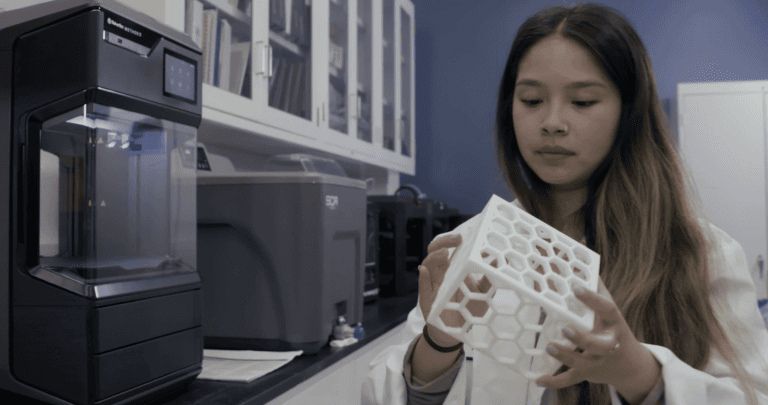

Developing Hardware for Biomanufacturing

The production of pharmaceuticals, vaccines, and antibodies is a highly intricate and innovative process that relies on technology matching its level of complexity. The vessels used in the procedure, called bioreactors, are designed to carry out the required chemical processes key to this industry. Inside is a tank in which growing organisms are submerged and suspended in a liquid solution where they can perform their desired function with limited production of impurities. In order to ensure a consistent, high-quality output, bioreactors are designed to control internal environmental factors such as temperature, nutrient concentrations, pH, and dissolved gases; all of which can drastically affect the growth and productivity of the contained organisms if not carefully regulated.

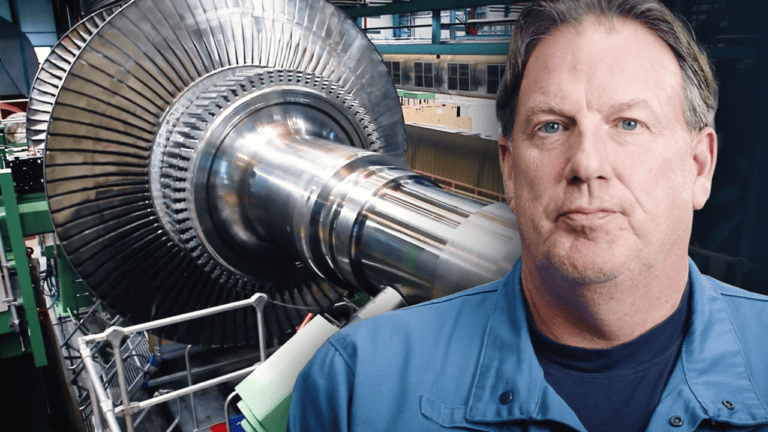

Using 3D optical scanning to reverse engineer industrial turbine spare parts

Meet Johan, director of Energetic Machinery in Belgium, and experience his passion for industrial steam turbines. Their company repairs and replaces turbomachinery components. They use optical 3D Scanning to capture existing geometry and reverse engineer replacement parts or plan their refurbishment. The portable nature of the GOM and ZEISS optical scanners allows them to go to the customer site accurately capture geometry.

Energetic Machinery is a classic example of how manufacturing companies across industries leverage #HandsOnMetrology to drive their reverse engineering efforts.

3D scanning helps in the creation of perfectly flush frames and in complex assemblies.

Meet Olivier from E-bike manufacturer Cowboy in Brussels. The company’s aim is to manufacture urban mobility solutions that offer amazing design, seamless usage, and affordability. At cowboy, they are pushing the boundaries of design, including a completely flush assembly even though it consists of different components. To achieve the precision they need, they leverage the power of 3D Scanning to capture their complex surface. That information is used to improve the design and make quick design iterations.

When we bought the Replicator series, it gave students more exposure to the technology, which resulted in increased interest and use.

Preparing students with the knowledge, skills, and resilience to embrace their future has always been at the crux of Abingdon School, an independent day and boarding school for boys, in Oxfordshire, England.

The school’s Design and Technology department offers a range of product design courses that aim to develop students’ technical knowledge and proficiencies. 3D modeling and design are taught alongside traditional manufacturing methods using woods, metals, and polymers.

Lockheed Martin Space uses METHOD X to create parts for the lunar rover project, enabling the engineers to design, develop, and test autonomous systems and processes

Lockheed Martin is a global aerospace and defense company, with the mission to connect, protect and explore. The company focuses on next-generation and generation-after-next technologies. In alliance with General Motors, Lockheed Martin is developing a new fully-autonomous lunar rover that could be used for NASA’s Artemis program. This is a fitting team that pays homage to the original Apollo rover, which GM was also involved in its development.

Some elements of the rover’s autonomy system’s early design and development is done at Lockheed Martin’s state-of-the art R&D facility in Palo Alto, Calif., the Advanced Technology Center (ATC), which is well-equipped with a variety of cutting-edge technology, including a lab full of 3D printers. MakerBot 3D printers have been in use for about five years and have provided easily accessible 3D printing for a host of projects for Lockheed Martin’s team of engineers.

Reinventing a High-Performance CPU Cooler with Additive Manufacturing

High heat loads limit the miniaturization of portable computers, power electronic devices and high-power LED lighting. Most ambitious technological solutions from the lab are not ready for mass production and deployment in consumer products. But industrial 3D printing, or so-called additive manufacturing, can bridge the gap for thermal

management components and keep lossy electronics cool even when the

available space is severely limited. The freedom of design provided by 3D printed thermal management components offers the same or superior effectiveness as conventionally manufactured components, but requires much less space. Enlarged surfaces, any-shape geometries and conformal cooling channels are among the opportunities of this manufacturing technology.

The efficiency gains that can be achieved were demonstrated with a gaming CPU cooler design for additive manufacturing. To maintain the same chip temperature, the new part requires 81 % less space and 93 % less weight than the best-in-class conventional cooler.

Simplified by Additive Manufacturing

Mission Critical”” perfectly describes the Class 1 components used in

the aerospace industry. Missions costing hundreds of millions depend

on these components. Accordingly, engineers are constantly seeking

to develop components of the highest quality, functionality, and

robustness while simplifying the manufacturing chain and reducing

the number of individual elements. Thanks to EOS technology, Ariane

Group has succeeded in taking this to a whole new level: Instead of

248 elements, the injector head of a rocket engine of a future upper

stage propulsion module now counts just 1 component. The injector

head has been simplified and reduced to what is literally an all-in-one design.

PRODUCTION FLOOR TRENDS: JUSTIFYING ADDITIVE MANUFACTURING THROUGH JIGS & FIXTURES

According to three owners of Stratasys Fortus machines, one-year profit gains ranged from $60,000 to $230,000 from just a few fixture-related applications.

There is an often-overlooked additive manufacturing (AM) application with potentially huge financial returns. Savings can be so large that they can justify the purchase of an AM (or 3D printing) system in far less time than the typical three- to fiveyear payback period the financial officer will demand. The application is jig and fixture making — which also includes gauges, organizational aids and other manufacturing devices. AM produces these tools by adding material in an automated, layer-by-layer process rather than removing material with a cutter or forming it in a mold.