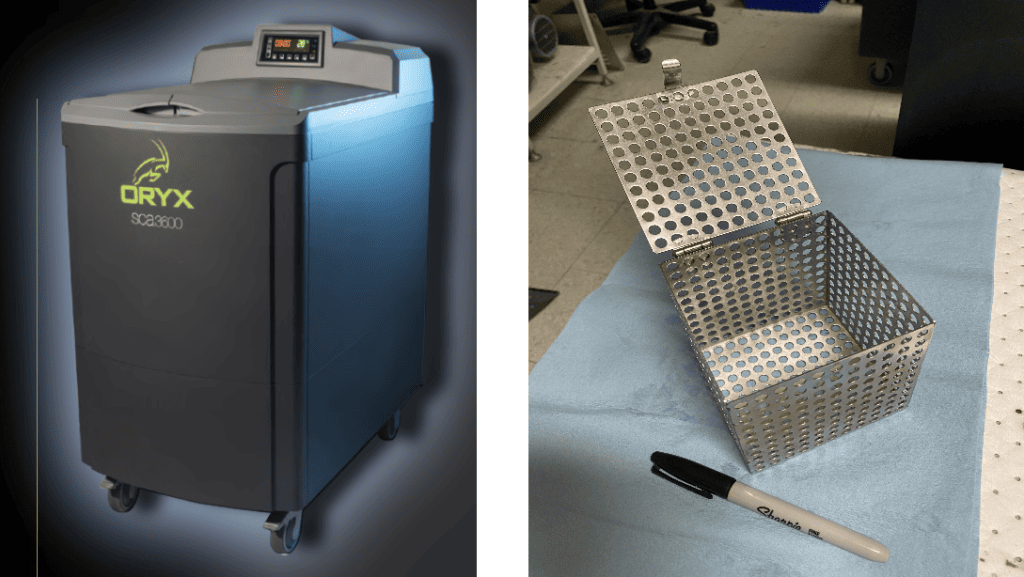

Ever print a filament-based part with soluble supports, that just wants to float in your tank? By tank, I mean the Support Cleaning Apparatus (SCA) tank offered by Stratasys that dissolves away support material that has been printed with one of the Stratasys FDM printers. PADT Inc. was the inventor/OEM of the SCA tank systems (now produced by spin-off company Oryx Additive) so we know them inside and out!

The tanks use a mild (about 2%) solution of sodium hydroxide in water that is heated to different temperatures depending on the type of filament. Each tank ships with a small, perforated metal (stainless-steel) basket with a hinged lid. This cube-shaped basket serves as a convenient holder to keep small parts together and makes it easy to retrieve them from the solution.

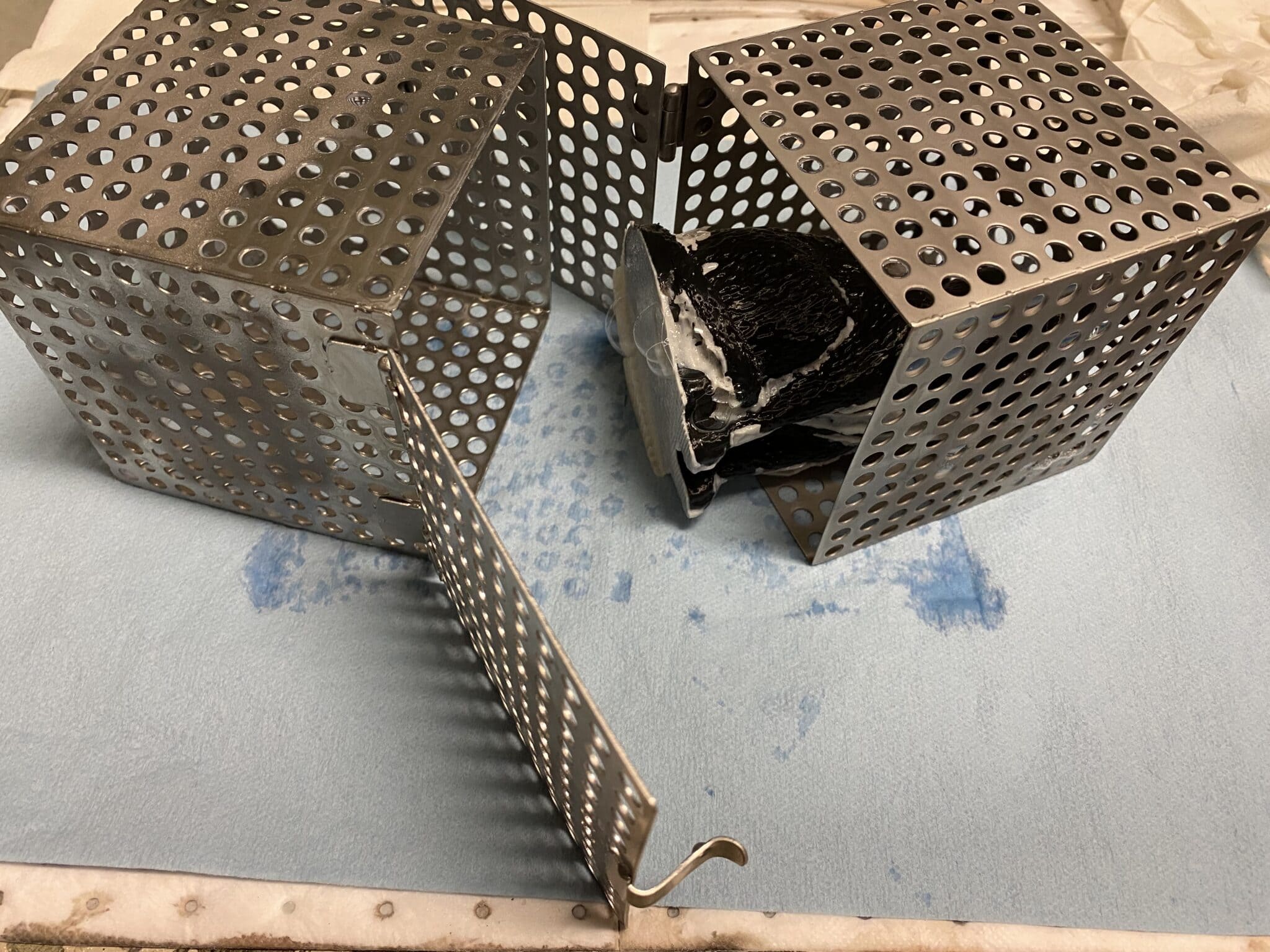

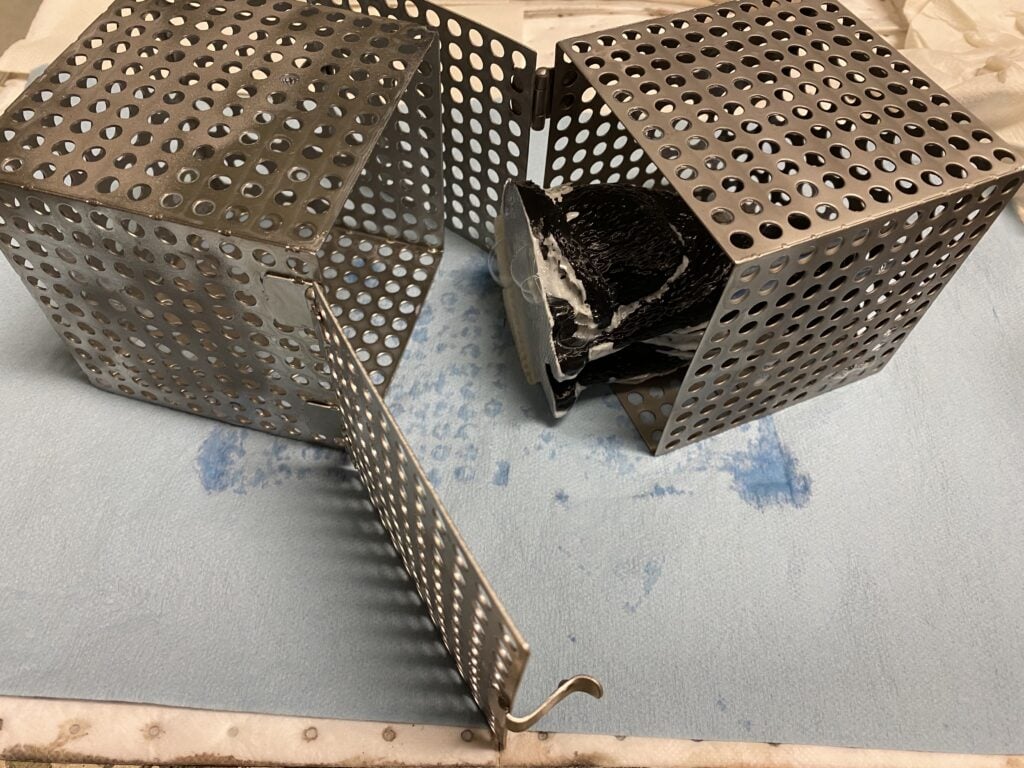

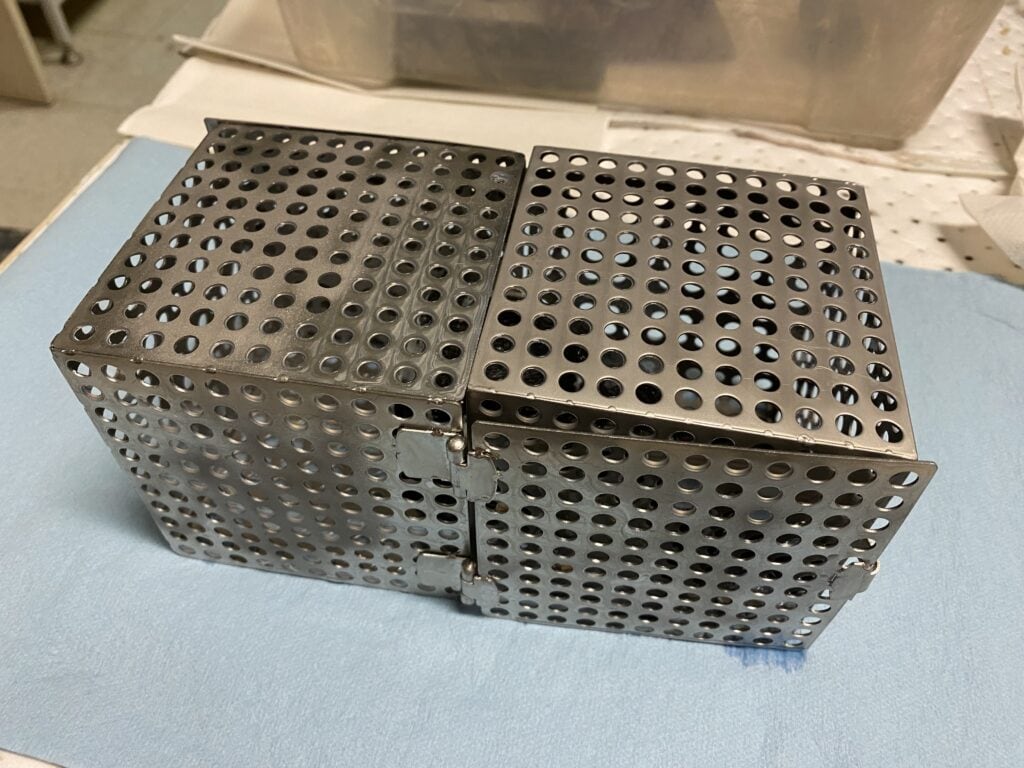

However, sometimes you have a part is too large for that cube, but was printed with a sparse infill, making it float and not always get evenly saturated with the liquid. Did you know that you can connect two cubes together to make one larger one? Check this out:

Load your part into one 4-inch cube but keep the lid open. Then snap the latch of the opened lid from one cube onto the top-edge of a second cube and repeat with the second lid snapped onto the opposite side. You now have a tank-box that is 4”x4”x8”. Place the double-cube into the SCA tank and watch it stay on the bottom, where full fluid-flow will reach all over it for the fastest clean-up time.

If your part is too large even for this approach, you can still convince a floating part to stay down deep. If your part has a hole in it, thread one end of a length of stainless-steel wire through that hole and twist the wire so it stays. Then thread the other end of the wire through any hole in the box, again twisting the end to stay in place. You’ve now converted the cube into an anchor that will hold your part down in the tank.

If there are no holes or slots in your part, wrap a longer piece of stainless-steel wire around the part itself, and then connect it through a hole in the cube to create the same anchor function.

Soluble supports for Stratasys filaments simplify printing complex geometries, so use these tips to simplify the support removal, too. If you’ve discovered other ways to achieve this goal (has anyone threaded SS nuts onto wire and wrapped it around a part?) please share it in the Comments.