On-Demand 3D Printing

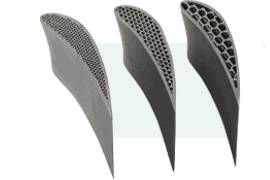

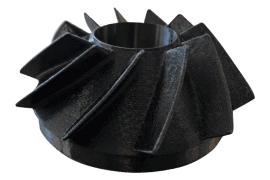

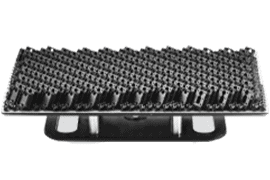

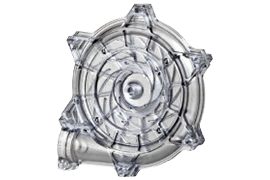

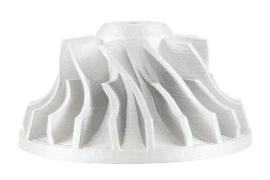

PADT has offered industry-leading 3D printing service for over 25 years.

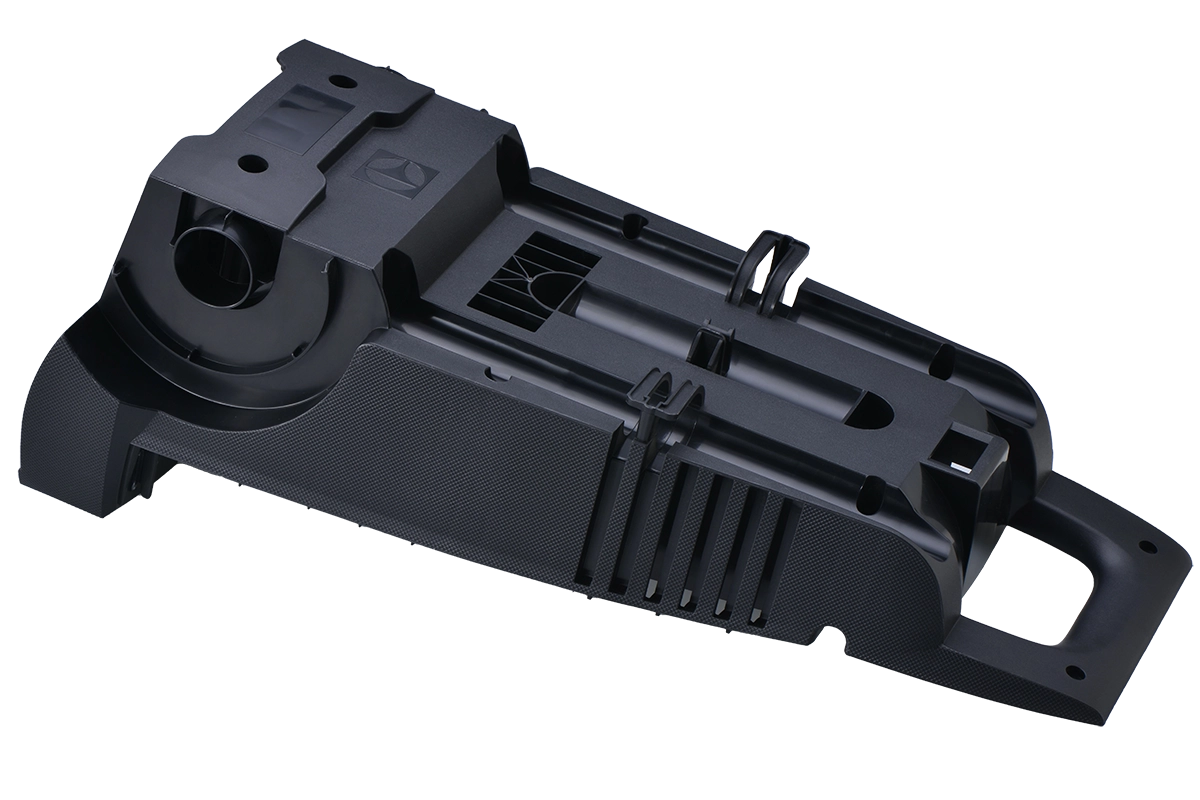

We can print your prototype or production parts using industrial additive manufacturing technologies. We are your one-stop-shop for precision 3D printed parts at a competitive price.

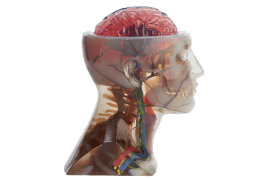

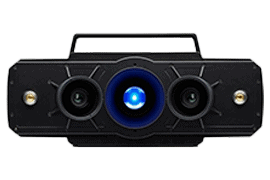

3D Scanning & Digitization

PADT offers state of the art 3D scanning services tailored to clients’ needs. From scanning and 3d digitization to 3D color mapping and forensic reports, we can provide any information you need.

AM Consulting & Training

Contract Manufacturing

Additive Manufacturing E3T Consulting Services

Additive Manufacturing (AM), is starting a paradigm shift in design and manufacturing. PADT is helping AM development and adoption by offering its AM E3T Consulting Program that will Engage you in discovering AM, Enable you to define how AM can change your business, Empower you to take on the AM adoption process, and help you Transform your business by re-inventing it using AM. We call this unique offering Additive Manufacturing E3T Consulting Services.

Our team of experts can offer training, or work with your organization to help you get the most out of your Additive Manufacturing investment. The best way for us to understand where your needs are and for you to get a handle on the benefits of PADT’s Additive Manufacturing E35 Consulting is to get together and talk.

PADT AM E3T Training Workshops

The AM E3T workshop is a hands-on training program of PADT’s comprehensive AM consulting services. The goal of this high-octane intensive workshop is to allow participants (1) to gain comprehensive overview of AM, and (2) to gain hands-on practice in AM technology and workflow. This workshop offers hands-on learning and experience in 4 key modules: Engage, Enable, Empower, and Transform. With this workshop under your belt, expect to discover what AM is and what it can do for your business, understand how AM technologies work, experience AM practice, and innovate your business with AM.

At the end of this workshop, participants will be able to:

- Describe differences between AM and SM, and cases where AM or SM is a better technology choice.

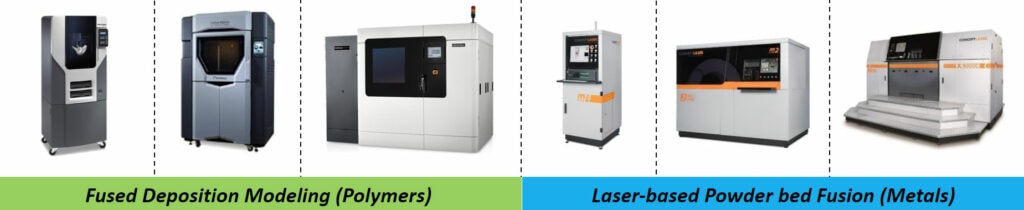

- Describe current AM technologies and their applications (Fused Deposition Modeling, Selective Laser Sintering, etc.).

- Select an appropriate AM process for a given set of product constraints.

- Describe the process flow for polymer and metal AM technologies.

- Completed a conceptual redesign of an assembly and determine quantitatively how AM reduced the cost of said assembly.

Topics of Discussion

- AM Trends

- Technology Landscape / Technology Comparison

- Use cases / Creating value with AM

- Technology Overview (with Lab tour/overview)

- Technology-specific workflow discussion

- Enable

- Technology-specific sessions

- Extrusion-based AM: FDM

- Materials Jetting AM: Polyjet

- Photopolymerization AM: SLA

- Photopolymerization AM: DLS

- Selective Laser Sintering of polymers: SLS

- Selective Laser Melting of Metals: DMLS

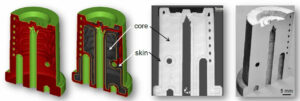

- Sample characteristics comparison

- Technology-specific sessions

- Empower

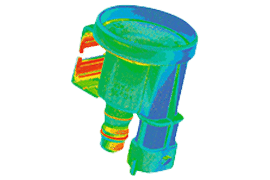

- Design for Manufacturing / Assembly / Additive Manufacturing

- Project discussion/presentation

- Safety / facility / maintenance

- Topology Optimization

- Transform

- AM Adoption Model: Reinvent your business

- AM R&D space

- Process / Material

- Digital Thread / AI / Industry 4.0

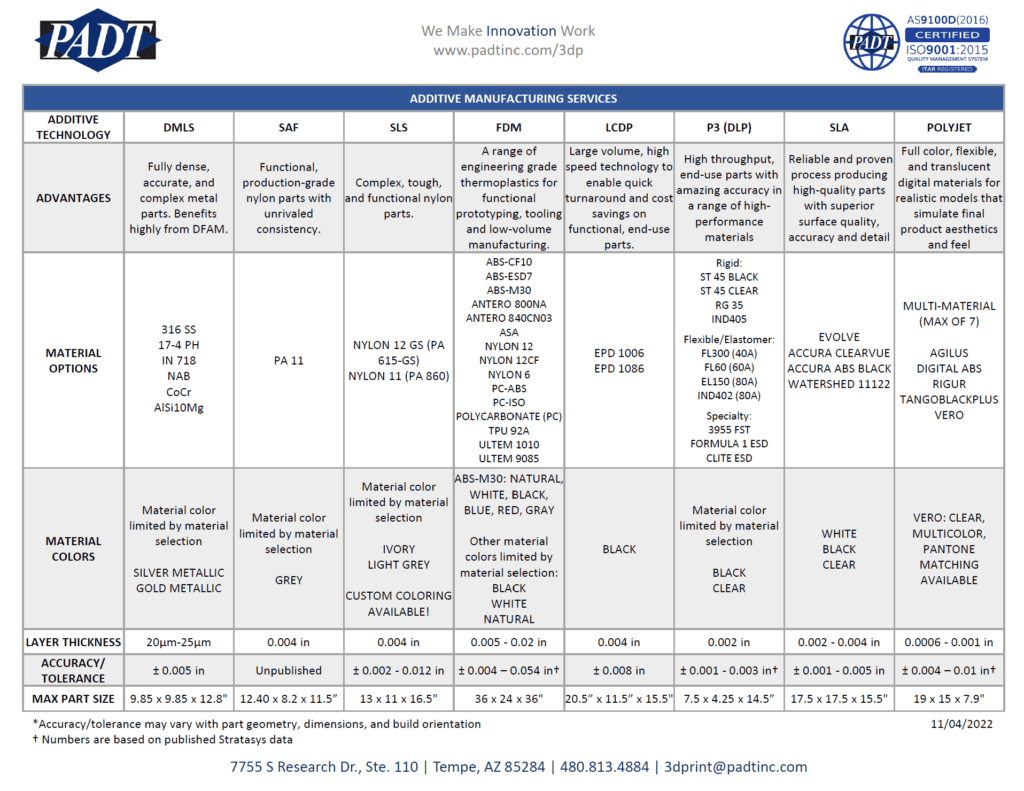

Download our Additive Manufacturing Services Summary

Download our handy one page summary for 3D Printing Services. It lists all the different technologies and materials PADT offers in-house. It’s free, we won’t even ask for your email.

PADT uses a variety of leading systems from Stratasys and EOS for the 3D Printing Services we offer. We added our first SLA printer in 1994, and are known worldwide for the quality of the parts we generate and the in-depth knowledge of our engineering staff. With PADT you have access to all the leading technologies for polymer and metal additive manufacturing, and to people who know how to use them to meet your needs.

Can't find what you're looking for?

PADT offers the most advanced Additive and Advanced Manufacturing Solutions available. If you have any questions or can’t find what you are looking for, fill out the form to the right or contact us using the following: