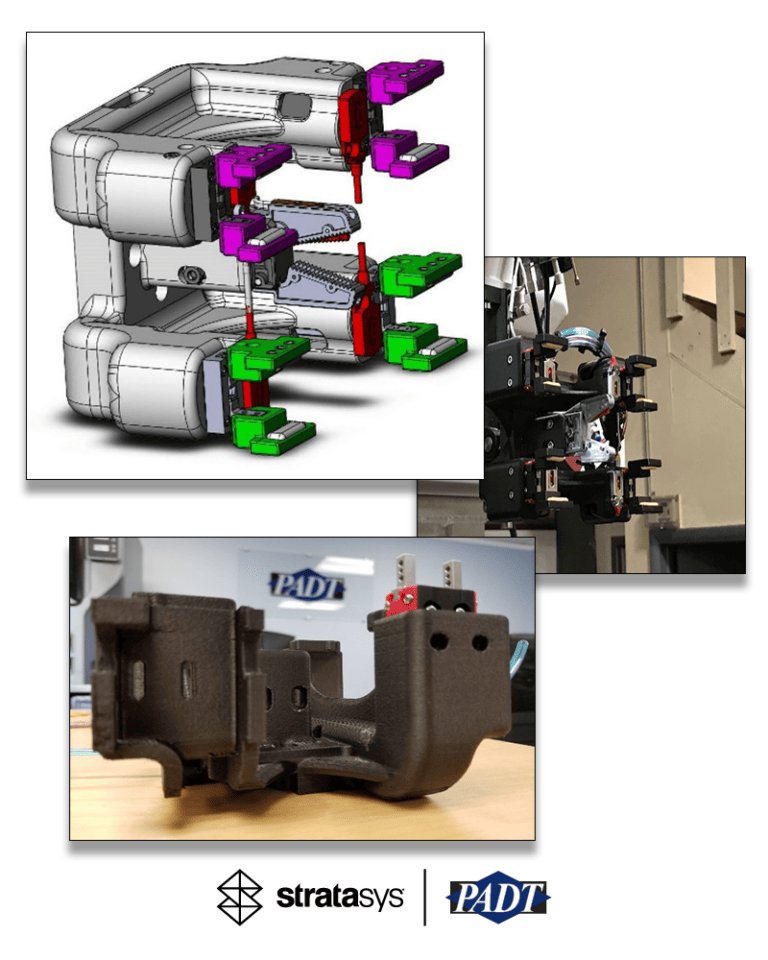

Robotics and Their Role in the Factory of the Future

In the factory of the future, automation is king. Manufacturers can drastically reduce lead times, reduce labor costs, and increase overall efficiency through the use of robotics at several stages in their workflow. These machines serve a variety of functions on the factory floor, including everything from gripping and positioning parts to welding and painting assemblies in the later stages of the manufacturing process. While each function serves a unique purpose specific to the task it will perform, they all utilize an essential component known as End-of-Arm tooling (EOAT).

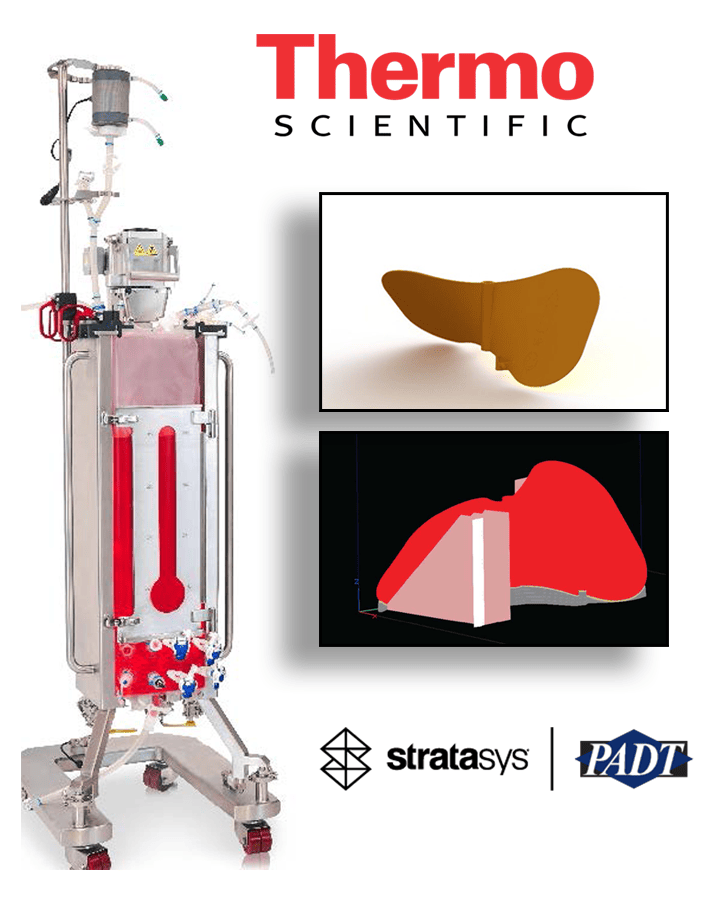

Developing Hardware for Biomanufacturing

The production of pharmaceuticals, vaccines, and antibodies is a highly intricate and innovative process that relies on technology matching its level of complexity. The vessels used in the procedure, called bioreactors, are designed to carry out the required chemical processes key to this industry. Inside is a tank in which growing organisms are submerged and suspended in a liquid solution where they can perform their desired function with limited production of impurities. In order to ensure a consistent, high-quality output, bioreactors are designed to control internal environmental factors such as temperature, nutrient concentrations, pH, and dissolved gases; all of which can drastically affect the growth and productivity of the contained organisms if not carefully regulated.

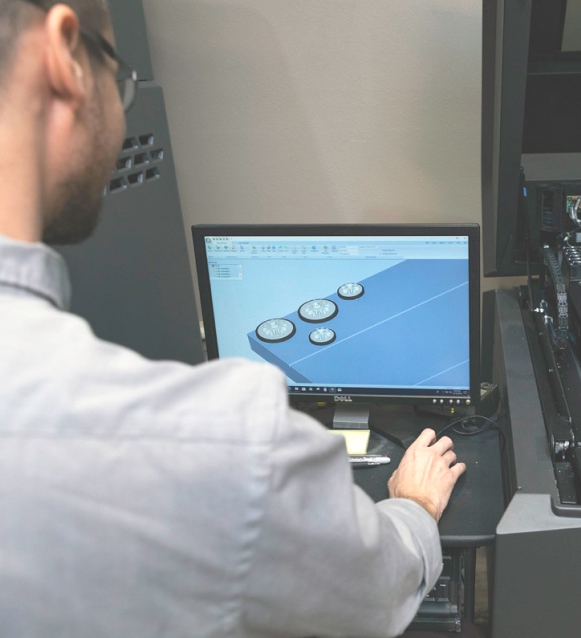

PRODUCTION FLOOR TRENDS: JUSTIFYING ADDITIVE MANUFACTURING THROUGH JIGS & FIXTURES

According to three owners of Stratasys Fortus machines, one-year profit gains ranged from $60,000 to $230,000 from just a few fixture-related applications.

There is an often-overlooked additive manufacturing (AM) application with potentially huge financial returns. Savings can be so large that they can justify the purchase of an AM (or 3D printing) system in far less time than the typical three- to fiveyear payback period the financial officer will demand. The application is jig and fixture making — which also includes gauges, organizational aids and other manufacturing devices. AM produces these tools by adding material in an automated, layer-by-layer process rather than removing material with a cutter or forming it in a mold.