Written by Dr. Keng Hsu – Associate Professor at ASU and PADT Principal AM R&D Engineer

STEM is awesome, but it’s the human imagination in between the S, T, E, and M that shapes the collective impact of these four letters, what they represent, and how they are applied. If you told a NASA engineer in the early 1960s that flight-ready engine parts could be made within weeks by feeding metal dust and some kind of binary code into a metal box that’s plugged into the wall, they would probably tell you that you belong in Hollywood…Thanks to the many with the ability and willingness to dream and invent, look at where we are today in metal 3D printing.

RAD Imagination of STEM

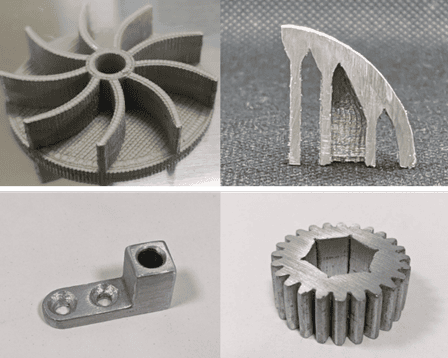

Through the same lens, we can see that the vibrant field of metal 3D printing has seen not only steady advancements in existing technologies getting better and more capable but there have also been (and probably there will almost always be) some new technologies being attempted and developed. Take for example, the Resonance Assisted Deposition (RAD) method, which utilizes solid metal wire feedstock and tiny little mechanical vibrations to join small sections of the wire continuously and form solid objects track-and-track and layer-by-layer. Some unique features of this technique are that there is no melting or excessive heating, the printing process takes place in ambient conditions without the need for vacuum or inert gas, simple system mechanics and workflow. Think about the overall process flow and machine mechanics of the FDM (FFF) technology, a 3D printer based on the RAD technology is practically the same, but with a different process physics, it now produces solid metal parts!

Now without getting geeky and looking into the process physics a little bit, it may be a little hard to see why this technique is nothing short of a poster child of STEM plus imagination!

Shaping and Joining in Metal 3D Printing

Let’s start by looking at manufacturing technologies in general. Really all that the various manufacturing technologies do is “change materials into the right shape and property”, and in that process, it turns raw materials into a product and adds value to it (beyond just the value of the material itself). Now this “shaping” is where many different methods can be utilized. For example, in a casting process, you heat and melt raw materials like aluminum and pour it into a prefabricated mold cavity. The liquid aluminum flows and conforms to the shape of the cavity. Once the aluminum cools and solidifies you break the mold, and voilà an aluminum part has been manufactured using casting. Similarly, you can cut, form, or even add to have the material take on a new shape (for example you “mill” a rectangular block of aluminum feedstock into an “L” shaped angle bracket, or “bend” a flat sheet of steel into a box, etc.) that meets the requirements for its function.

Another important piece that is critical to manufacturing is joining, be it to form a permanent or temporary joint. In the “L” shaped bracket example above, you could choose to weld, or permanently join two flat pieces of aluminum together to form the “L” shape, instead of machining it from a block. There are many ways to join metals, including controlled melting and re-solidification, or it can be without melting. This can be done by using optical, mechanical, or even mechanical forms of energy. For example, friction-stirred welding allows you to join two metal rods (end-to-end) by pressing them tightly together while one is spinning at a high speed. This causes large amounts of friction, heating the interface to be joined. When the two sides of metal across the interface get hot enough, the fundamental process of “diffusion” happens to cause an exchange of matter (or metal atoms) from both sides, and the joining is accomplished. At this point, the “interface” no longer exists and what used to be materials on the two sides of the “interface” are now a continuous phase, in most cases chemically and metallurgically. All of this happens without the base metals actually melting.

In metal 3D printing, both shaping and joining are required. A lot of times simultaneously while each unit volume of the overall 3D object is formed, whether the unit is a voxel, a line, or a whole layer. For example, in Laser Powder Bed Fusion, when the laser beam strikes the bed of metal powder, it heats and melts the powder which forms a melt pool of metal, which once solidified, forms the unit volume of an overall object. So in this process, the shaping (from spherical particles to the typically little cone-shaped solid) and joining (joining the discrete powder particle and joining the cone-shaped solids into a track as the laser scans, and tracks into layers as the laser rasters) happens, for all practical purposes, at the same time.

Feedstock in Metal 3D Printing

Onto the STEM plus imagination idea…Currently, in almost all metal 3D printing processes, the shaping and joining of feedstock during the process is accomplished (or assisted) by heating the feedstock. Whether the heat is caused by hitting it with a laser beam, electron beam, or running an electrical current to cause Joule heating, spark, or plasma, it all has to do with the fundamental fact that heating the material changes its properties in a way that favors shaping and joining. Actually, from an even broader point of view, this very way of using heat is not only something that’s been practiced since the dawn of human’s ability to make things thousands of years ago, but it is also the scientific principle that sits at the core of numerous industrialized manufacturing processes.

The question is though, is “heating” really the only way to perform or assist shaping and joining? Well, the answer is an emphatic “no”.

There is existing scientific knowledge that tells us the effect of heating material can be obtained through other means without ever heating the material. The application of this scientific knowledge in the development of engineering and technology is where the imagination can really shine and create an invention. Case in point, the RAD technique that we briefly introduced earlier harnesses the scientific principle of how metal atoms (and the “lattice defects” where they are missing in the material) move around when mechanical vibrations are propagating through it, sharing strong similarities to how they move when metal is being heated. The former has a more structured collective movement, while the latter tends to be a bit random. As long as you can find a way to introduce and control these structured movements in the atoms and lattice defects, it can be used to allow/assist shaping and joining. This really is what’s at the heart of RAD. It uses tiny vibrations (we are talking structured vibrations at the surface at around 1-micrometer amplitude, but at relatively high frequencies in the tens of thousands of Hertz range) to soften, shape, and joint small sections of a solid metal wire into a 3D object. As far as how exactly the small structured collective vibrations cause the shaping and joining, it’s a topic for another day, but know that it’s proven to work. Of course, the “secret sauce” lies in exactly how you apply and control the tiny vibrations, and knowing what “knobs” you can turn to make it just right. But this is also a topic for another day…for now.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development, and 3D Printing 3D Scanning products and services. For more information, please contact us at 3dprint@padtinc.com and connect with us on Instagram for more content!

Title Images from EOS