Most histories of Additive Manufacturing (3D printing) trace the origins of the technology back to Charles Hull’s 1984 patent, the same year production began on the first of the Back to the Future movies. Which is something of a shock when you see 3D printing dotting the Gartner Hype Cycle like it was invented in the post-Seinfeld era. But that is not what this post is about.

When I started working on Additive Manufacturing (AM), I was amazed at the number of times I was returning to text books and class notes I had used in graduate school a decade ago. This led me to reflect on how AM is helping bring back to the forefront disciplines that had somehow lost their cool factor – either by becoming part of the old normal, or because they contained ideas that were ahead of their time. I present three such areas of research that I state, with only some exaggeration, were waiting for AM to come along.

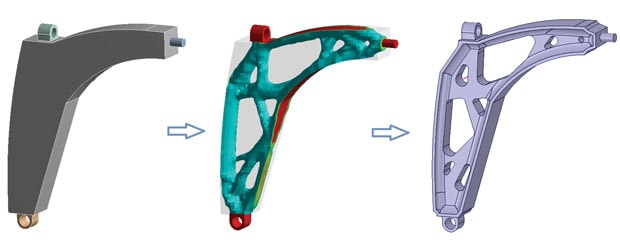

- Topology Optimization: I remember many a design class where we would discuss topology optimization, look at fancy designs and end with a conversation that involved one of the more cynical students asking “All that’s fine, but how are you going to make that?”. Cue the elegant idea of building up a structure layer-by layer. AM is making it possible to manufacture parts with geometries that look like they came right out of a stress contour plot. And firms such as ANSYS, Autodesk and Altair, as well as universities and labs are all working to improve their capabilities at the intersection of topology optimization and additive manufacturing.

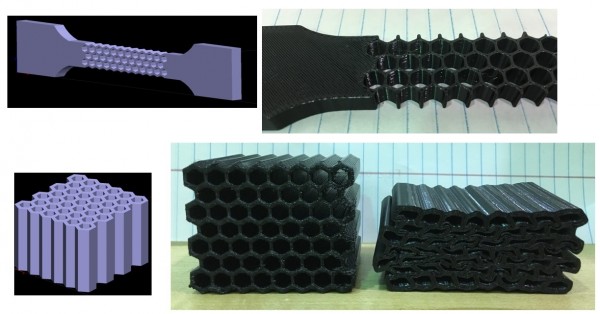

- Lattice Structures: One of the first books I came across when I joined PADT was a copy of Cellular Solids by Lorna Gibson and M.F. Ashby. Prof. Gibson’s examples of these structures as they occur in nature demonstrate how they provide an economy of material usage for the task at hand. Traditionally, in engineering structures, cellular designs are limited to foams or consistent shapes like sandwich panels where the variation in cell geometry is limited – this is because manufacturing techniques do not normally lend themselves well to building complex, three dimensional structures like those found in nature. With AM technologies however, cell sizes and structures can be varied and densities modified depending on the design of the structure and the imposed loading conditions, making this an exciting area of research.

Lattice specimens made with the Fused Deposition Modeling (FDM) process

- Metallurgy: As I read the preface to my “Metallurgy for the Non-Metallurgist” text book, I was surprised to note the author openly bemoan the decline of interest in metallurgy, and subsequently, fewer metallurgists in the field. And I guess it makes sense: materials science is today mostly concerned with much smaller scales than the classical metallurgist trained in. Well, lovers of columnar grain growth and precipitation hardening can now rejoice – metallurgy is at the very heart of AM technology today – most of the projected growth in AM is in metals. The science of powder metallurgy and the microstructure-property-process relationships of the metal AM technologies are vital building blocks to our understanding of metal 3D printing. Luckily for me, I happen to possess a book on powder metallurgy. And it too, is from 1984.