“Why are there so many different software solutions in Additive Manufacturing and which ones do I really need?“

This was a question I was asked at lunch during the recently concluded RAPID 3D printing conference by a manager at an aerospace company. I gave her my thoughts as I was stuffing down my very average panini, but the question lingered on long after the conference was over – several weeks later, I decided to expand on my response in this blog post.

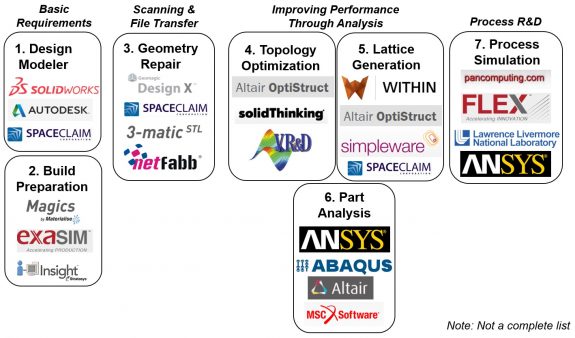

There are over 25 software solutions available and being used for different aspects of Additive Manufacturing (AM). To answer the question above, I found it best to classify these solutions into four main categories based on their purpose, and allow sub-categories to emerge as appropriate. This classification is shown in Figure 1 below – and each of the 7 sub-categories are discussed in more detail in this post.

Basic Requirements

1. Design Modeler

You need this if you intend to create or modify designs

Most designs are created in CAD software such as SOLIDWorks, CATIA and SpaceClaim (now ANSYS SpaceClaim). These have been in use long before the more recent rise in interest in AM and most companies have access to some CAD software internally already. Wikipedia has a comparison of different CAD software that is a good starting point to get a sense of the wide range of CAD solutions out there.

2. Build Preparation

You need this if you plan on using any AM technology yourself (as opposed to sending your designs outside for manufacturing)

Once you have a CAD file, you need to ensure you get the best print possible with the printer you have available. Most equipment suppliers will provide associated software with their machines that enable this. Stand-alone software packages do exist, such as the one developed by Materialise called Magics, which is a preferred solution for Stereolithography (SLA) and metal powder bed fusion in particular – some of the features of Magics are shown in the video below.

Scanning & File Transfer

3. Geometry Repair

You need this if you deal with low-quality geometries – either from scans or since you work with customers with poor CAD generation capabilities

Geomagic Design X is arguably the industry’s most comprehensive reverse engineering software which combines history-based CAD with 3D scan data processing so you can create feature-based, editable solid models compatible with your existing CAD software. If you are using ANSYS, their SpaceClaim has a powerful repair solution as well, as demonstrated in the video below.

Improving Performance Through Analysis

4. Topology Optimization

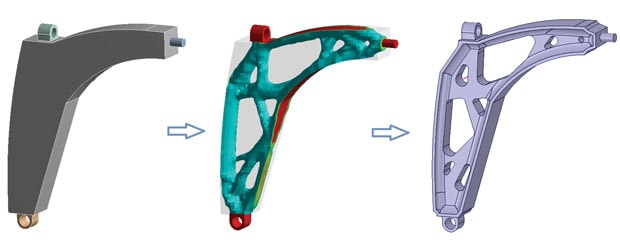

You need this if you stand to benefit from designing towards a specific objective like reducing mass, increasing stiffness etc. such as the control-arm shown in Figure 2

Of all the ways design freedom can be meaningfully exploited, topology optimization is arguably the most promising. The ability to now bring analysis up-front in the design cycle and design towards a certain objective (such as maximizing stiffness-to-weight) is compelling, particularly for high performance, material usage sensitive applications like aerospace. The most visible commercial solutions in the AM space come from Altair: with their Optistruct solution (for advanced users) and SolidThinking Inspire (which is a more user-friendly solution that uses Altair’s solver). ANSYS and Autodesk 360 Inventor also offer optimization solutions. A complete list, including freeware, can be availed of at this link.

5. Lattice Generation

You need this if you wish to take advantage of cellular/lattice structure properties for applications like such as lightweight structural panels, energy absorption devices, thermal insulation as well as medical applications like porous implants with optimum bone integration and stiffness and scaffolds for tissue engineering.

Broadly speaking, there are 3 different approaches that have been taken to lattice design software:

- Infill or Conformal Lattice Design: ANSYS SpaceClaim, Magics, Simpleware, Paramount Industries, NetFabb

- Topology Optimization Driven Lattice Design: Altair OptiStruct

- Generative Design: Autodesk Within

I will cover the differences between these approaches in detail in a future blog post. A general guideline is that the generative design approach taken by Autodesk’s Within is well suited to medical applications, while Lattice generation through topology optimization seems to be a sensible next step for those that are already performing topology optimization, as is the case with most aerospace companies pursuing AM technology. The infill/conformal approach is limiting in that it does not enable optimization of lattice structures in response to an objective function and typically involves a-priori definition of a lattice density and type which cannot then be modified locally. This is a fast evolving field – between new software and updates to existing ones, there is a new release on an almost quarterly, if not monthly basis – some recent examples are nTopology and the open source IntraLattice.

Below is a short video demo of Autodesk’s Within:

6. Analysis

You need this if you do either topology optimization or lattice design, or need it for part performance simulation

Basic mechanical FE analysis solvers are integrated into most topology optimization and lattice generation software. For topology optimization, the digitally represented part at the end of the optimization typically has jarring surfaces that are smoothed and then need to be reanalyzed to ensure that the design changes have not shifted the part’s performance outside the required window. Beyond topology optimization & lattice design, analysis has a major role to play in simulating performance – this is also true for those seeking to compare performance between traditionally manufactured and 3D printed parts. The key challenge is the availability of valid constitutive and failure material models for AM, which needs to be sourced through independent testing, from the Senvol database or from publications.

Process Development

7. Process Simulation

You need this if you would like to simulate the actual process to allow for improved part and process parameter selection, or to assess how changes in parameters influence part behavior

The real benefit for process simulation has been seen for metal AM. In this space, there are broadly speaking two approaches: simulating at the level of the part, or at the level of the powder.

- Part Level Simulation: This involves either the use of stand-alone AM-specific solutions like 3DSIM and Pan Computing (acquired by Autodesk in March 2016), or the use of commercially available FE software such as ANSYS & ABAQUS. The focus of these efforts is on intelligent support design, accounting for residual stresses and part distortion, and simulating thermal gradients in the part during the process. ANSYS recently announced a new effort with the University of Pittsburgh in this regard.

- Powder Level Simulation: R&D efforts in this space are led by Lawrence Livermore National Labs (LLNL) and the focus here is on fundamental understanding to explain observed defects and also to enable process optimization to accelerate new materials and process research

Part level simulation is of great interest for companies seeking to go down a production route with metal AM. In particular there is a need to predict part distortion and correct for it in the design – this distortion can be unacceptable in many geometries – one such example is shown in the Pan Computing (now Autodesk) video below.

https://youtu.be/uGXPlsPRlA0

A Note on Convergence

Some companies have ownership of more than one aspect of the 7 categories represented above, and are seeking to converge them either through enabling smooth handshakes or truly integrate them into one platform. In fact, Stratasys announced their GrabCAD solution at the RAPID conference, which aims to do some of this (minus the analysis aspects, and only limited to their printers at the moment – all of which are for polymers only). Companies like Autodesk, Dassault Systemes and ANSYS have many elements of the 7 software solutions listed above and while it is not clear what level of convergence they have in mind, all have recognized the potential for a solution that can address the AM design community’s needs. Autodesk for example, has in the past 2 years acquired Within (for lattice generation), netfabb (for build preparation) and Pan Computing (for simulation), to go with their existing design suite.

Conclusion: So what do I need again?

What you need depends primarily on what you are using AM technologies for. I recommend the following approach:

- Identify which of the 4 main categories apply to you

- Enumerate existing capabilities: This is a simple task of listing the software you have access to already that have capabilities described in the sub-categories

- Assess gaps in software relative to meeting requirements

- Develop an efficient road-map to get there: be aware that some software only make sense (or are available) for certain processes

In the end, one of the things AM enables is design freedom, and to quote the novelist Toni Morrison: “Freedom is not having no responsibilities; it is choosing the ones you want.” AT PADT, we work with design and analysis software as well as AM machines on a daily basis and would love to discuss choosing the appropriate software solutions for your needs in greater detail. Send us a note at info@padtinc.com and cite this blog post, or contact me directly on LinkedIn. .

Thank you for reading!