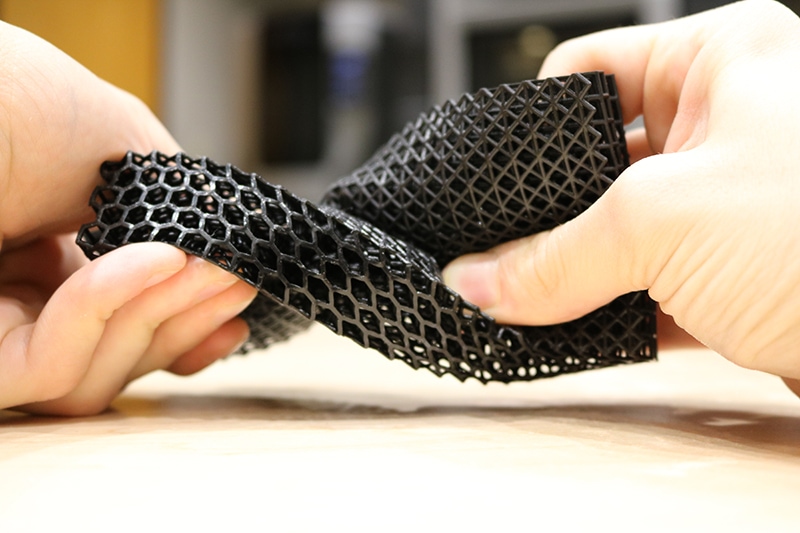

We chose to leverage Carbon’s technology because of the three key differentiators in their system:

- Digital light projection is much faster than a laser or print head.

- Oxygen permeable optics enables accurate project while keeping the part from sticking to the optics.

- Programmable liquid resins produce parts with excellent mechanical properties, resolution and surface finish.

Please read the press release below for more details on the opening of our facility.

You can also find more information here:

- On-Demand Manufacturing Web Page

- Background on Carbon’s DLS Technology, including a great video that explains it all.

- Our On-Demand Manufacturing Brochure

Please find the official press release on this new partnership below and here in PDF and HTML

Now is the time to explore production using Additive Manufacturing. If you have plastic parts that you want to manufacture using 3D Printing, contact Renee Palacios at renee@padtinc.com or 480.813.4884.

Press Release:

New Digital Manufacturing Facility for On-Demand Delivery

of Production Quality Parts Opened at PADT

A Carbon Certified Production Partner, PADT Enables Customers to Make Cost-Effective Parts Quickly with Near-Injection Molded Material Properties

“Since we started in 3D Printing almost 25 years ago, we have dreamed of the day that we could use additive manufacturing to move beyond prototyping and deliver production parts to our customers when they need them, the way they need them,” said Rey Chu, co-founder and principal, PADT. “Carbon’s DLS technology has made this possible by giving us a faster process that creates parts with the same properties as injection molding.”

“Our goal is to deliver true, scalable digital fabrication across the globe, enabling creators to design and produce previously unmakeable products, both economically and at scale,” said Dana McCallum, head of Production Partnerships at Carbon. “PADT has a long history in the industry and a strong reputation for engineering excellence. We’re thrilled to have them as a certified Carbon production partner.”

PADT’s Digital Manufacturing Facility, the Southwest’s first true “3D Printing factory,” is now open to customers. For more information about On-Demand Manufacturing with Carbon, please visit PADT’s site here or call 1-800-293-PADT. For more information about Carbon, visit www.carbon3d.com.

About Phoenix Analysis and Design Technologies

Phoenix Analysis and Design Technologies, Inc. (PADT) is an engineering product and services company that focuses on helping customers who develop physical products by providing Numerical Simulation, Product Development, and 3D Printing solutions. PADT’s worldwide reputation for technical excellence and experienced staff is based on its proven record of building long-term win-win partnerships with vendors and customers. Since its establishment in 1994, companies have relied on PADT because “We Make Innovation Work.” With over 80 employees, PADT services customers from its headquarters at the Arizona State University Research Park in Tempe, Arizona, and from offices in Torrance, California, Littleton, Colorado, Albuquerque, New Mexico, Austin, Texas, and Murray, Utah, as well as through staff members located around the country. More information on PADT can be found at www.PADTINC.com.

# # #

| Media Contact Alec Robertson TechTHiNQ on behalf of PADT 585-281-6399 alec.robertson@techthinq.com |

PADT Contact Eric Miller PADT, Inc. Principal & Co-Owner 480.813.4884 eric.miller@padtinc.com |