Fasteners are one of the most common and fundamental engineering components we encounter.

Proper design of fasteners is so fundamental, every Mechanical Engineer takes a University course in which the proper design of these components is covered (or at least a course in which the required textbook does so).

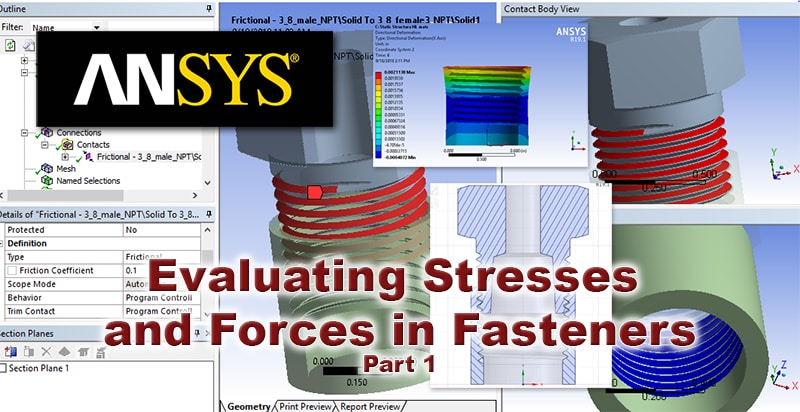

With recent increases in computational power and ease in creating and solving finite element models, engineers are increasingly tempted to simulate their fasteners or fastened joints in order to gain better insights into such concerns as thread stresses

In what follows, PADT’s Alex Grishin demonstrates a basic procedure for doing so, assesses the cost/benefits of doing so, and lays the groundwork for some further explorations in Part 2, which can now be found here.