Getting zapped by static electricity at the personal level is merely annoying; having your sensitive electronic equipment buzzed is another, highly destructive story.

Much as you’d like to send these components out into the world wearing their own little anti-static wristbands, that’s just not practical (and actually, not good enough*). During build and use, advanced electronics applications need true charge-dissipative protection that is inherent to their design and easy to achieve. However, the typical steps of painting or coating, covering with conductive tape, or wrapping with carbon-filled/aluminum-coated films incur both time and cost.

Electrostatic dissipative (ESD) polymer materials instead provide this kind of protection on a built-in basis, offering a moderately conductive “exit path” that naturally dissipates the charge build-up that can occur during normal operations. It also prevents powders, dust or fine particles from sticking to the surface. Whether the task is protecting circuit boards during transport and testing, or ensuring that the final product works as designed throughout its lifetime, ESD materials present low electrical resistance while offering the required mechanical, and often thermal and/or chemically-resistant properties.

Combining ESD Behavior with 3D Printing

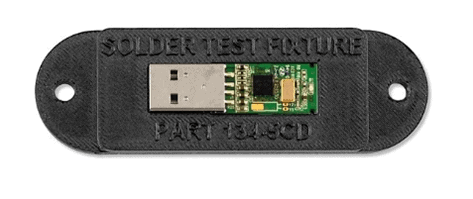

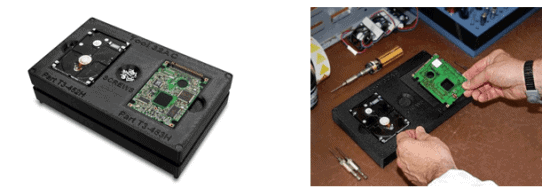

All the features that are appealing with 3D printing carry over when printing with ESD-enabled thermoplastics. You can print trays custom-configured to hold circuit-boards for in-process testing, print conformal fixtures that speed up sorting, and produce end-use structures for projects where static build-up is simply not allowed (think mission-critical aerospace applications).

Acrylonitrile butadiene styrene (ABS), that work-horse of the plastics industry, has been available as 3D printing filament for decades. Along the way, Stratasys and other vendors started offering this filament in a version filled with carbon particles that decrease the plastic’s inherent electrical resistance. Stratasys ABS-ESD7 runs on the Fortus 380, 400, 450 and 900 industrial systems, and soon will be available on the office-friendly F370 printer.

What kind of performance does ABS-ESD7 offer? When evaluating materials for ESD performance, the most important property is usually the surface resistance, measured in ohms. (This is not the same as surface resistivity, plus there’s also volume resistivity – see Note at end). Conductive materials – typically metals – have a surface resistance generally less than 103 ohms, insulators such as most plastics are rated at greater than 1012 ohms, and ESD materials fall in the mid-range, at 106 to 109 ohms.

Compared to standard ABS filament, ABS-ESD7 offers more than five orders of magnitude lower resistance, converting it from an insulator to a material that provides an effective static-discharge path to the outside world. Due to the inherent layered structure of FDM parts, the differences in properties between flat (XY) and vertical (ZX) build orientations produces a range of resistance values, with a target of 107 ohms, reflected in the product name of ABS-ESD7. Stratasys offers an excellent, easy-to-read FAQ paper about ABS-ESD7.

When ABS isn’t strong enough or won’t hold up to temperature extremes, engineers can turn to Stratasys’ ESD-enhanced polyetherketoneketone (PEKK), termed Antero 840CN03. Developed in 2016 and slated for full release in October 2019, this new filament expands the company’s Antero line of high-temperature, chemically resistant formulations. The PEKK base material offers a high glass transition temperature (Tg 149C, compared to 108C for ABS-ESD7) while meeting stringent outgassing and cleanroom requirements. As with ABS-ESD7, the carbon-nanotube loading lowers electrical resistance values of Antero 840CN03 parts to the desirable “ESD safe” range of 106 to 109 ohm.

Setting up Parts for Printing with ESD-Enhanced Filament

Support structures in contact with part walls/surfaces can disturb the surface resistance behavior. To counter-act this condition for filament printing with any type of ESD material, users should perform a special calibration that makes the printer lay down slightly thinner-than-usual layers of support material. In Stratasys Insight software, this is currently accomplished by setting the Support Offset Thickness to -0.003; this decreases the support layers from 0.010 inches to 0.007 inches. In addition, supports should be removed (in Insight software) from holes that are smaller in diameter than 0.25 inches (6.35mm).

As more of these materials are developed, the software will be updated to automatically create supports with this process in mind.

ESD Applications for 3D Printing

Avionics boxes, fixtures for holding and transporting circuit boards, storage containers for fuel, and production-line conveyor systems are just a few examples of end-use applications of ESD-enabled materials. Coupled with the geometric freedom offered by 3D printing, three categories of manufacturing and operations are improved:

- Protecting electronics from ESD damage (static shock)

- Preventing fire/explosion (static spark)

- Preserving equipment/product performance (static cling)

If you’re exploring how 3D printing with ESD-enhanced materials can help with your industrial challenge, contact our PADT Manufacturing group: get your questions answered, have some sample parts printed, and discover what filament is right for you.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing products and services. For more information on Insight, GrabCAD and Stratasys products, contact us at info@padtinc.com.

*Anti-static is a qualitative term and refers to something that prevents build-up of static, rather than dissipating what does occur

Surface Resistance, Surface Resistivity and Volume Resistivity

Surface resistance in ohms is a measurement to evaluate static-dissipative packaging materials.

Surface resistivity in ohms/square is used to evaluate insulative materials where high resistance characteristics are desirable. (Ref. https://www.evaluationengineering.com/home/article/13000514/the-difference-between-surface-resistance-and-surface-resistivity)

The standard for measuring surface resistance of ESD materials is EOS/ESD S11.11, released in 1993 by the ESD Association as an improvement over ASTM D-257 (the classic standard for evaluating insulators). Driving this need was the non-homogeneous structure of ESD materials (conductive material added to plastic), which had a different effect on testing parameters such as voltage or humidity, than found with evaluating conductors.

Volume resistivity is yet a third possible measured electrical property, though again better suited for true conductors rather than ESD material. It depends on the area of the ohmeter’s electrodes and the thickness of the material sample. Units are ohm-cm or ohm-m.