When we engineers are building a new system or iterating on an existing design it can be expensive. Simulating a full system-level model in a 3D CFD program can take days. Making iterative changes to an existing system can be costly or even impossible. Utilizing a one-dimensional system modeler like Flownex allows us to analyze many different designs very quickly, on the order of seconds or minutes.

Flownex is a thermal-fluid network modeler. It is a simulation tool that allows for 1D fluid modeling and 2D heat transfer. It uses a variety of flow components, nodes, and heat transfer elements to model the entire system we are interested in analyzing. It solves conservation of mass, momentum, and energy to obtain the mass flow, pressure, and temperature of fluids and solids throughout the complete network. Because of this approach we can analyze large, complex networks very quickly, iterate on designs, and even run short or long transient simulations with ease.

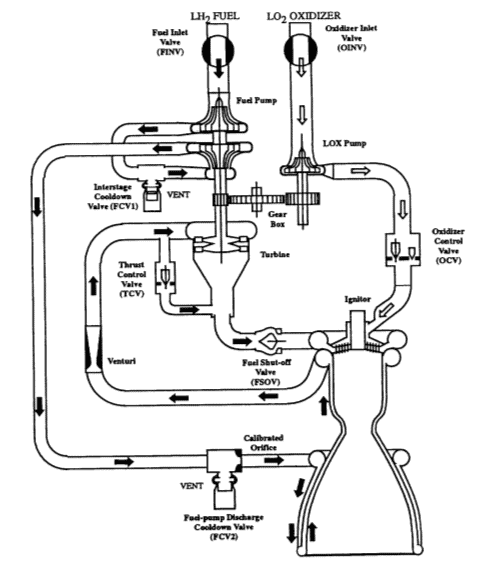

In the example today we are looking at a version of the RL-10 rocket engine, which has been a staple in the delivery of satellites into orbit and an essential part of many spacecraft. The specific iteration of the RL-10 we will be using for building our network model is the RL10A-3-3A. A good place to begin with any system model is a system schematic:

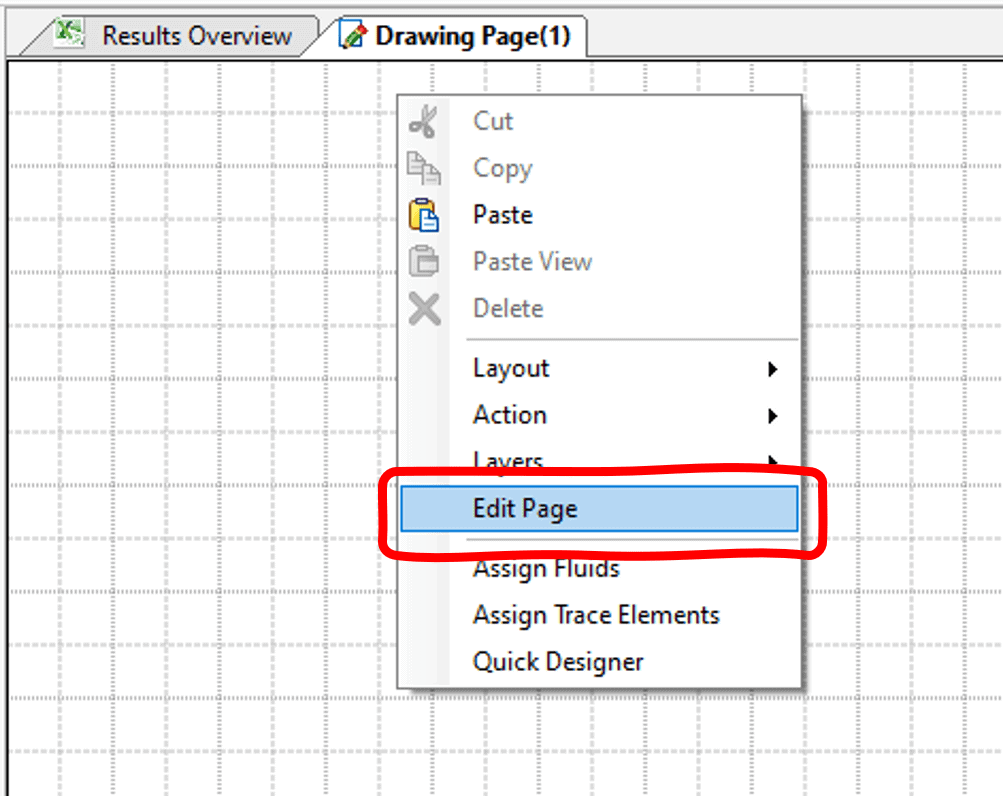

In Flownex we can assign an image (could be from a P&ID diagram, a CAD cross-section, or even a satellite image!) as the background for our drawing canvas. We simply need to right-click on the drawing canvas and select Edit Page to bring up the drawing canvas properties.

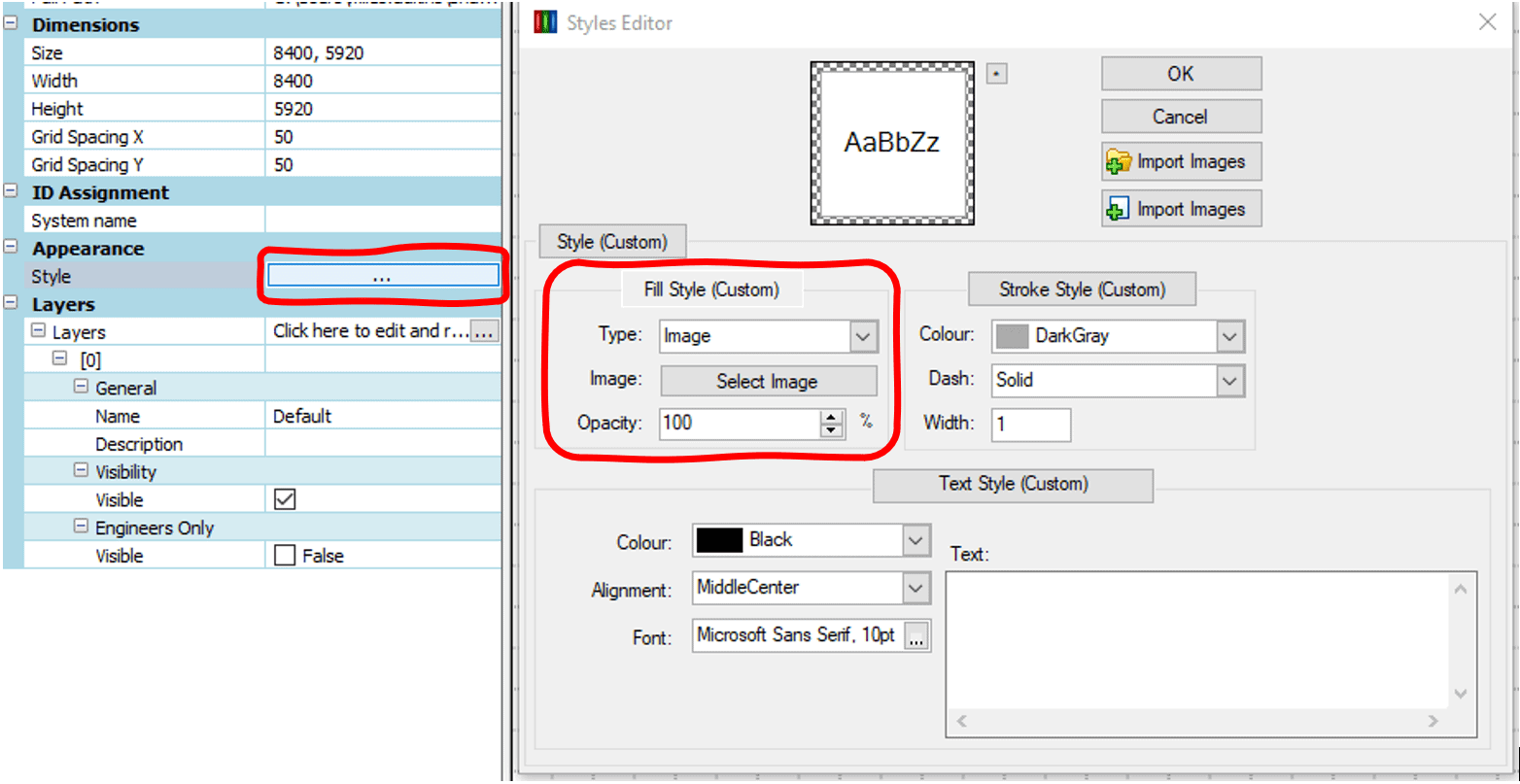

Clicking on the action button under Appearance > Style brings up the Styles Editor. Here we can change the fill style to Image and select the appropriate image for our background.

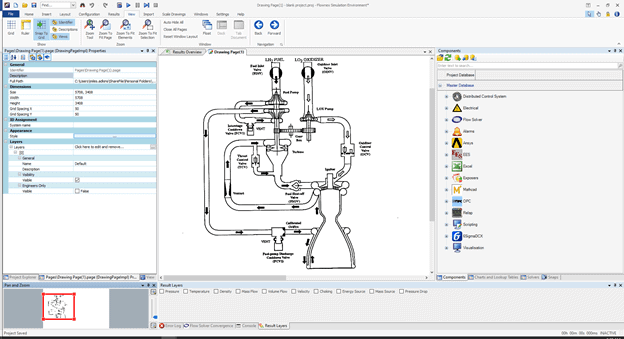

In the case of the RL-10 we can use the image from figure 2 as our background image. We may want to consider adjusting the opacity of the image so that it blends into the background a little bit more.

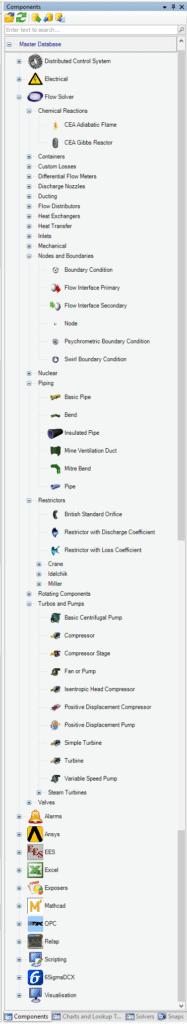

In Flownex building a system model is as simple as drag and drop. We can build our rocket engine using a variety of flow components from the Flow Solver library. To build the RL-10 system model we will be using the following components:

CEA Adiabatic Flame component to model combustion.

Composite Heat Transfer component to model thermal transport through pipe-walls to ambient and to model the regen.

Boundary Conditions to constrain our system at the inlets and outlet.

Basic Valves to model the different valves in the system,

Flow Resistances to model specified losses where appropriate.

Flow Interfaces to model the fluids entering the combustion chamber (to transfer fluid properties as we switch from two-phase O2 and H2 to gaseous fluids for modeling combustion.

Pipes for modeling various flow-paths.

Restrictors with Discharge Coefficient for our injection ports to the combustion chamber.

Restrictors with Loss Coefficient to model both the Calibrated Orifice and the Venturi contraction/expansion.

Basic Centrifugal Pumps for our Fuel and LOX pumps.

Simple Turbine to model the Fuel Turbine

Shafts to connect our different pumps mechanically.

Gearbox is used to connect the shafts between the LOX pump and the Fuel Pump.

Exit Thrust Nozzle to determine total thrust.

A Script is used in assigning O2 properties prior to combustion.

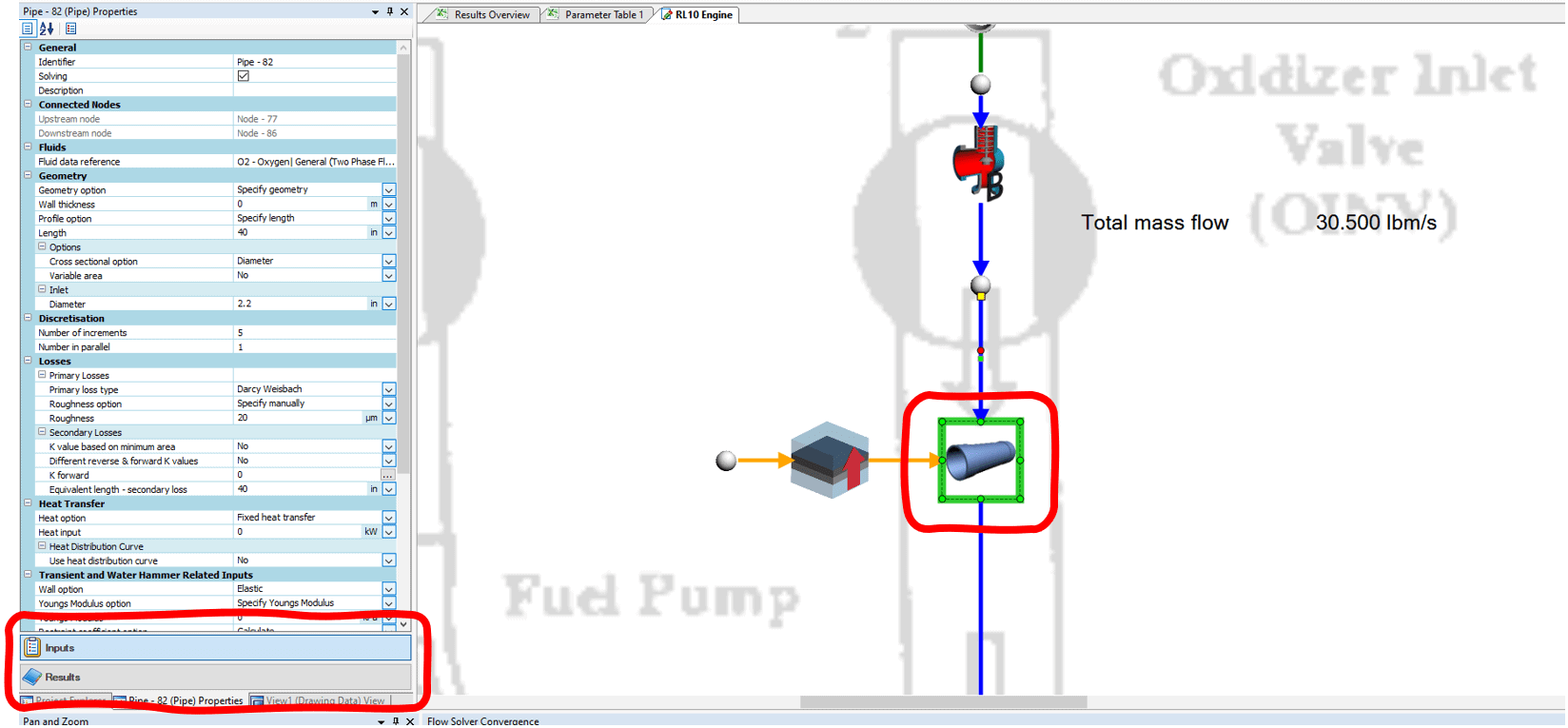

The components may be dragged and dropped from the component library onto the drawing canvas to build our system model. We can also copy and paste components that are already on the canvas into different locations. This can be especially useful when the same inputs for say, a pipe, are used consistently throughout the model. All components have both Inputs and a Results associated with them as seen in the figure below. This is how we will define our flow components.

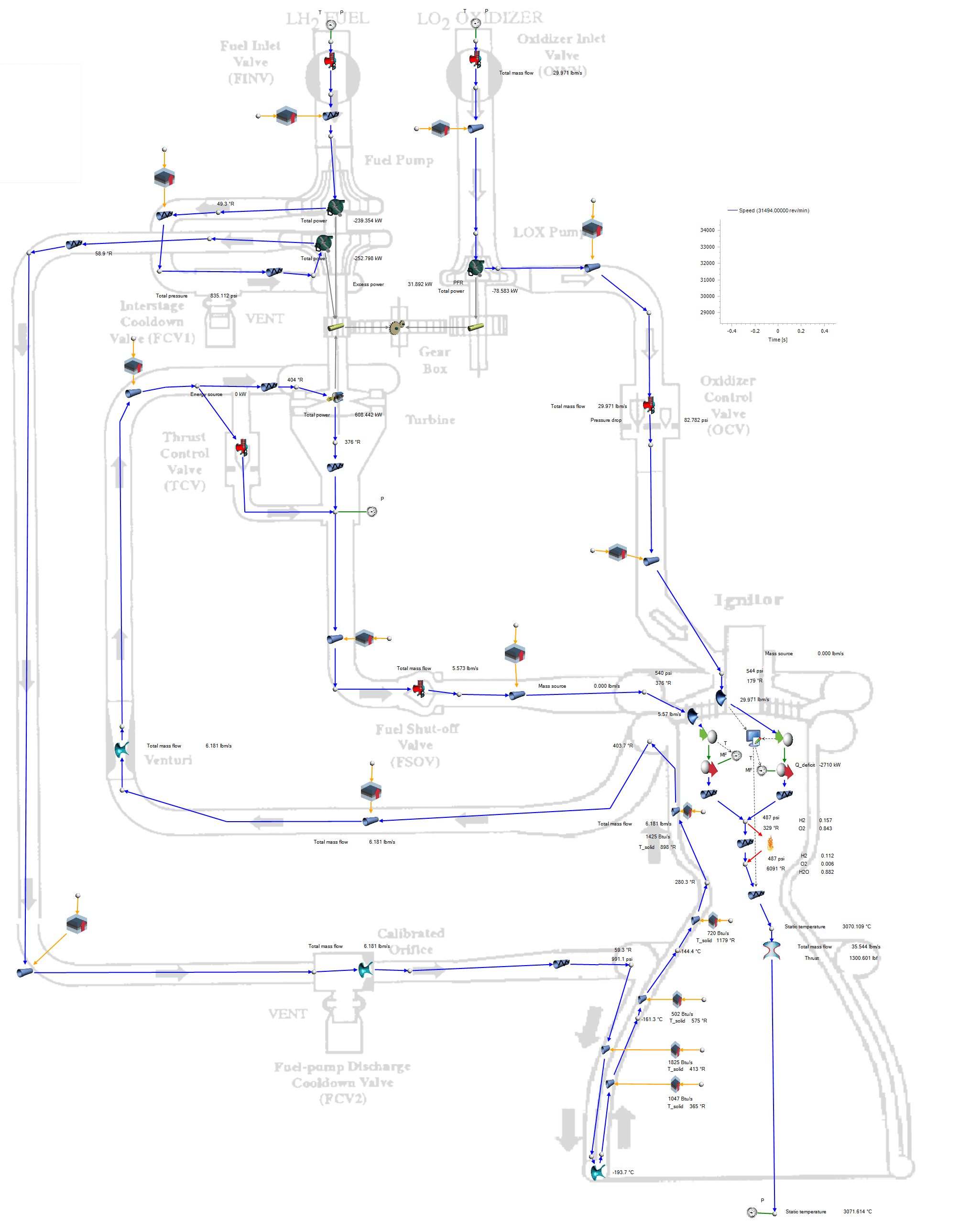

The completed model of the RL-10 Rocket Engine can be seen below. There are a few simplifications; we are using composite heat transfer components to model free convection to a specified ambient temperature (as though this was a land-based test). Rather than tie the actual temperatures and flow conditions in the nozzle to the regen we are using assumed temperatures and convective heat transfer coefficients. For additional fidelity we could model the heat transfer between these two flow paths with calculated convective heat transfer coefficients and we could model cross-conduction along the pipes which deliver the fuel and oxidizer to the combustion chamber. With additional effort, more complex use cases could also be simulated.

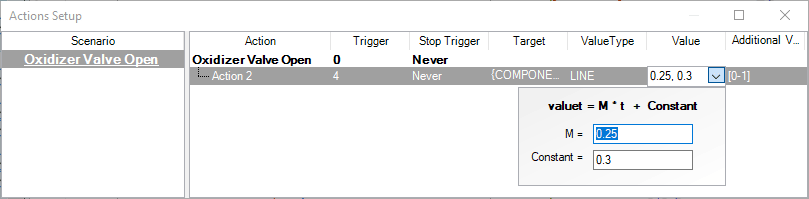

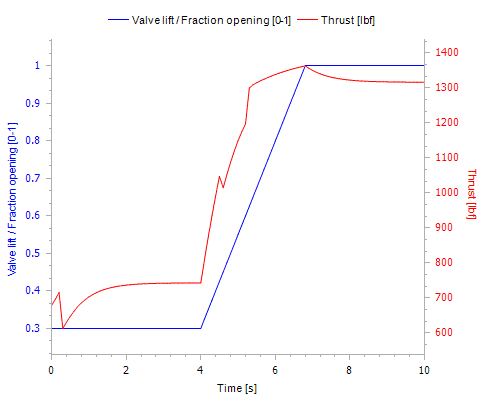

For the sake of demonstration we set up a transient action to slowly vary the oxidizer control valve fraction open; starting at 30% and ending at 100% open and observer the change in thrust at the nozzle as a function of this changing transient action.

Plots may be easily added by dragging a Line Graph from the Visualization > Graphs section of the component library onto our canvas. To choose the characteristics we would like plotted against time we simply need to drag and drop the desired inputs or results onto our newly placed line graph.

We can plot both the oxidizer control valve fraction open and the thrust versus time to observe the thrust reaction to the opening of the valve. The thrust plot has some jumps that are likely due to numerical singularities – with additional work this could be improved.

As can be seen, setting up complex system models in Flownex is relatively simple with most operations being drag and drop. For ease of sharing models with colleagues or customers adding a background image makes it very easy to see how the flow components in the model correspond with a system schematic. Setting up and plotting the effects of operational transients is a breeze!

For more information on Flownex please reach out to Dan Christensen at dan.christensen@padtinc.com.