Recently I had the chance to start printing parts on PADT’s new Stratasys Origin One 3D printer, and now I can’t get enough of it. It creates parts by curing a shallow tray of liquid resin, a full layer at a time, based on DLP (digital light processing) technology. That means, whether you print just one part or as many as can fit on the build-platform, the print-time is the same. If you’re accustomed to filament-based printing, this system is FAST, and the resulting surface finish rivals that of injection-molded parts.

The Origin One’s DLP process is termed Programmable PhotoPolymerization (P3, for short, because of course we need another acronym in this field). The photocurable resins it uses are single-component materials, which simplifies the build process compared to those that require two-part epoxies: there’s no waste since parts can print overnight, and each open resin vat can stay open for a week.

In addition, unused resin can be strained and returned to the bottle, easily lasting a month, while unopened resins display a six-month-to-one-year shelf-life. And what a range of resins and applications! The Origin One system is open; several material companies (Henkel Loctite, Covestro Somos and BASF) have already worked with the printer’s developers, matching the hardware’s operation with the best build-prep parameters for their formulas.

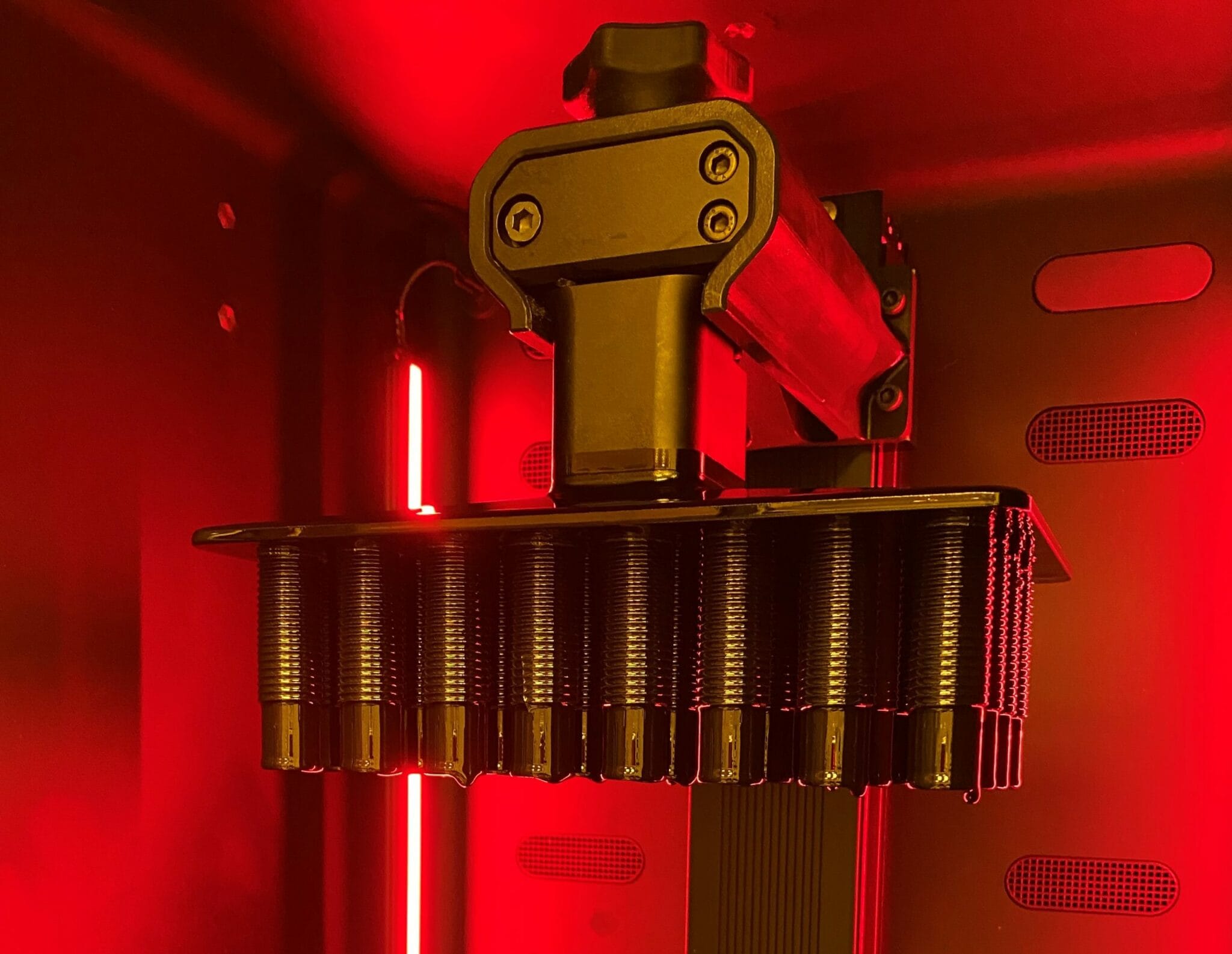

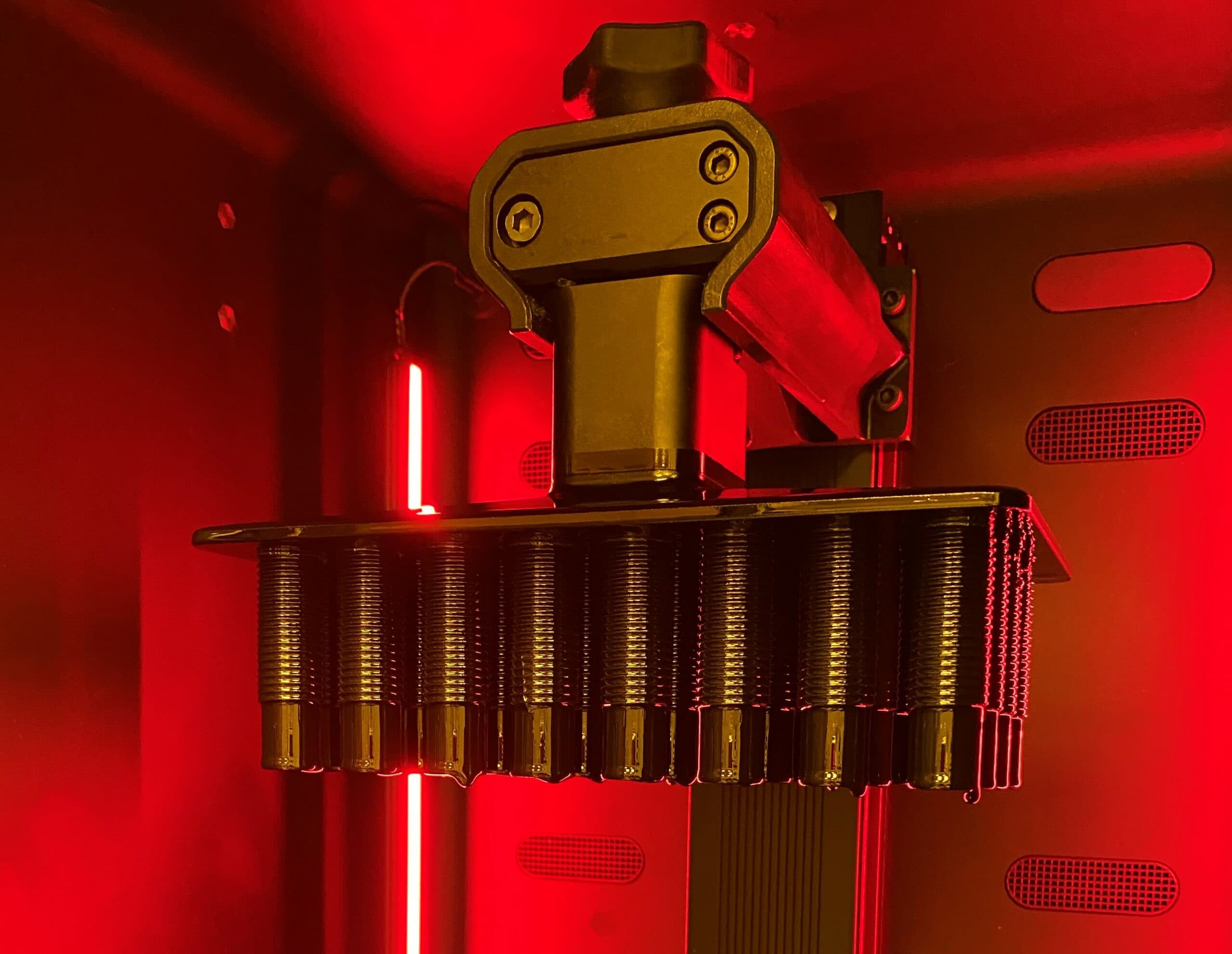

All P3 resins are tuned to 385 nanometers. The combination of this wavelength, shorter than that of other DLP and LCD systems, along with a 4K light engine, supports feature sizes as small as 50 microns and strong molecular cross-linking for exceptional material properties. Printing across a build platform that is 7.5 inches by 4.25 inches, the typical build layer is 100 microns, and the proprietary pneumatic release mechanism (key to great adhesion plus speed) easily supports layer print-times of 15 seconds. The build volume height is 14.5 inches, which can accommodate a decently large number of parts; you may have seen how Origin helped develop and print thousands of certified nasal-swabs in the first months of the COVID pandemic (approximately 1500 swabs every eight hours).

Print Setup

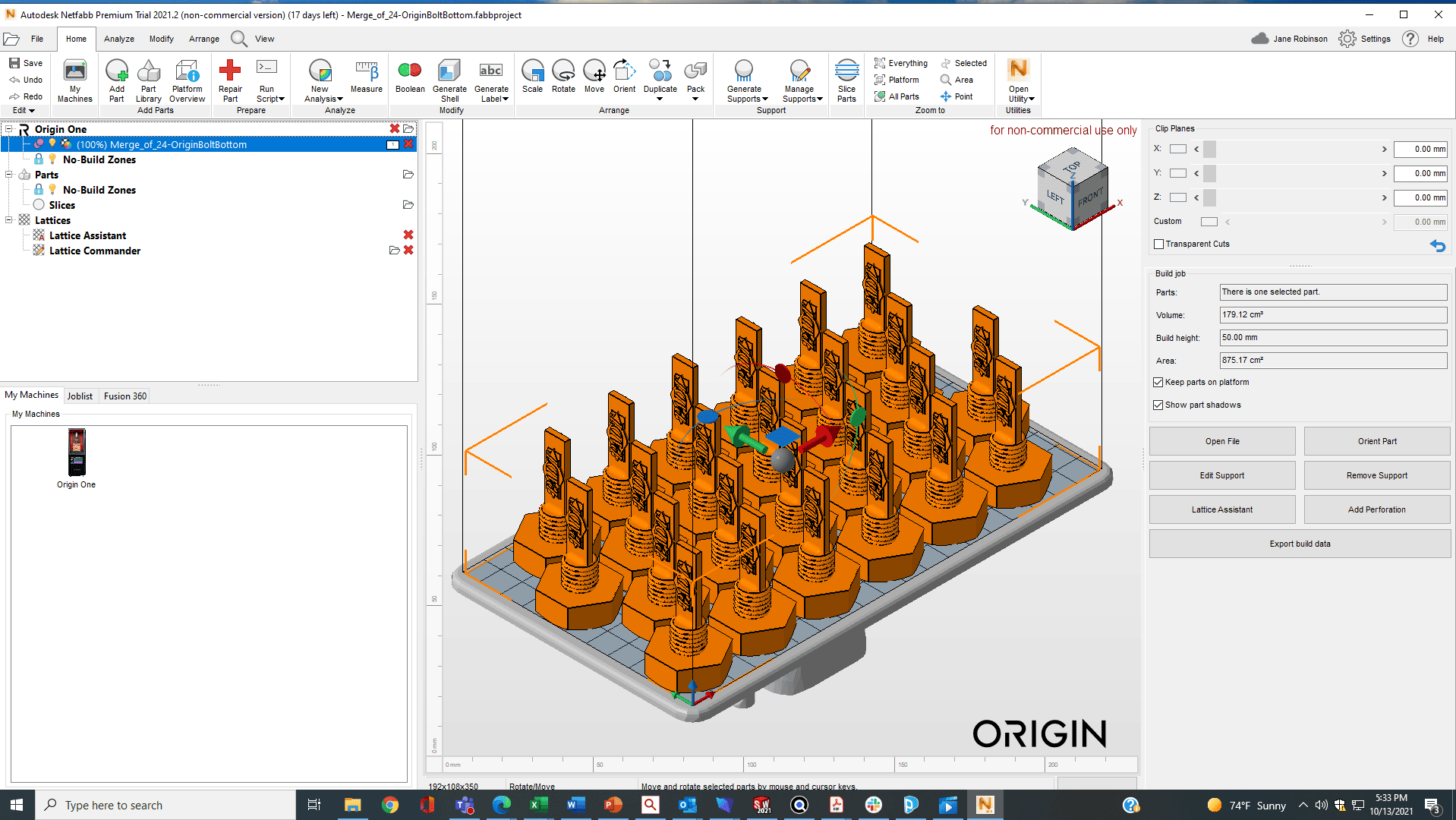

If you already have Autodesk netfabb Premium software, you’ve got what you need to prepare an STL part file for printing; if not, the Origin One printer comes with the first-year free of netfabb, or you can use other file preparation software such as Materialise Magics. Depending on the part geometry, you may place the parts directly on the build platform (as with typical DLP printers, the parts print upside-down), or you can choose to add supports of many styles; these will be snipped off during post-processing.

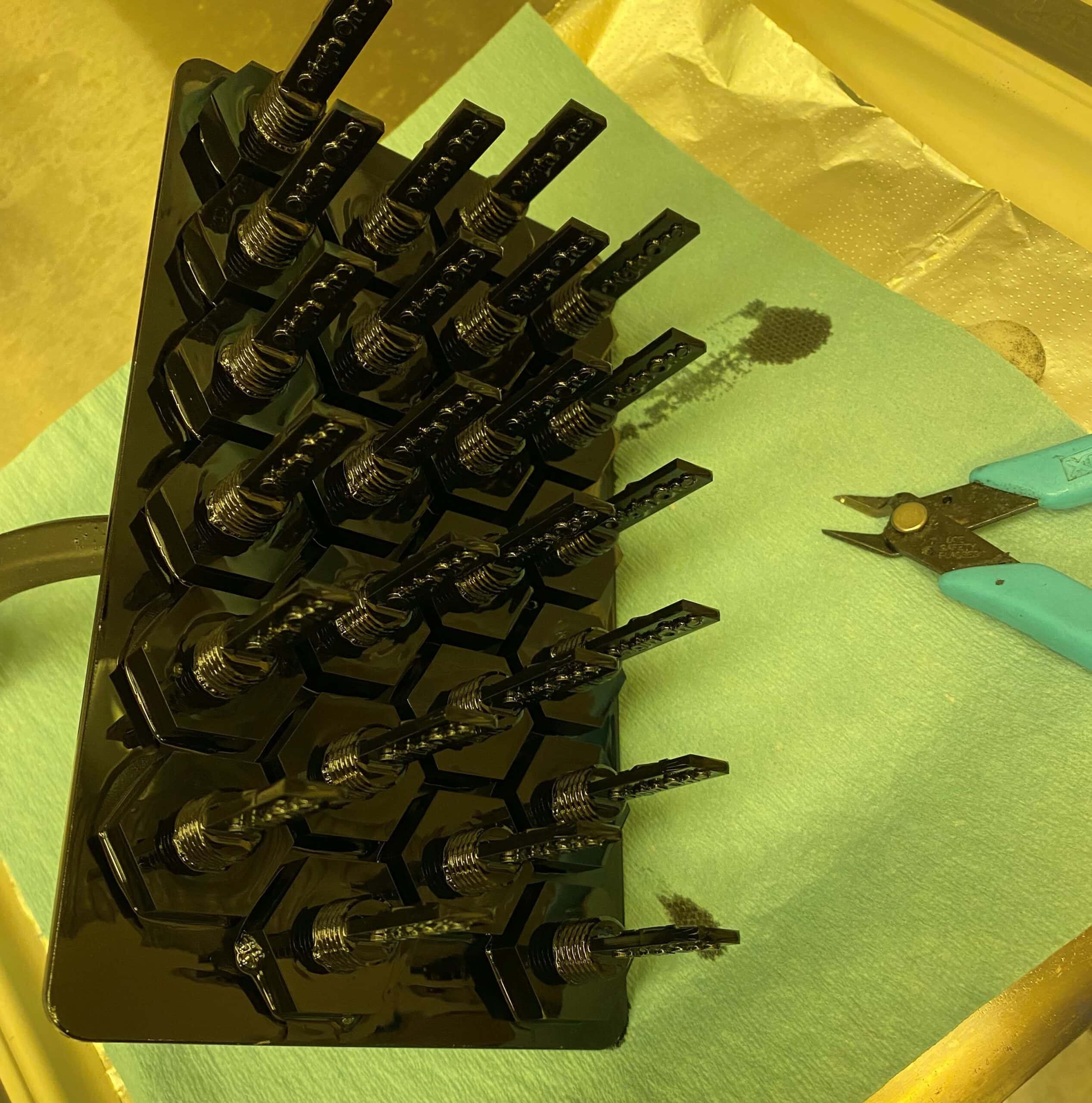

Post-Processing

This is fast, too! I found I could complete the post-processing workflow in 30 minutes to an hour, and of that only about 20 minutes was hands-on time. Here are the recommended steps:

- Swish the build-platform with the parts still on it, in a tub of IPA, for about 5 seconds.

- Slide the parts off with a putty knife, or just pop them off with gloved hands.

- Rinse the parts in agitated IPA for five to ten minutes. (We use an automated shaker-table unit, but sonicator units are also an option.)

- Air-dry the parts with compressed air.

- Cure the parts in a UV oven for anywhere from 30 seconds to 20 minutes or so, depending on the material, geometry and oven power.

- Done!

Geometry Design Capabilities

The feature size that can be achieved with this system is pretty impressive:

– As small as 0.5mm diameter cylinder (8mm tall),

– As small as 0.2mm diameter horizontal through-holes, and

– Up to a 3mm unsupported 90-degree overhang.

Material categories

So far, Stratasys has qualified the set-up parameters for 12 resins, some of which are available in more than one color or in clear. These materials offer options for the following use cases.

- Heat-resistant

- Tough

- General purpose

- Elastomers

- Medical

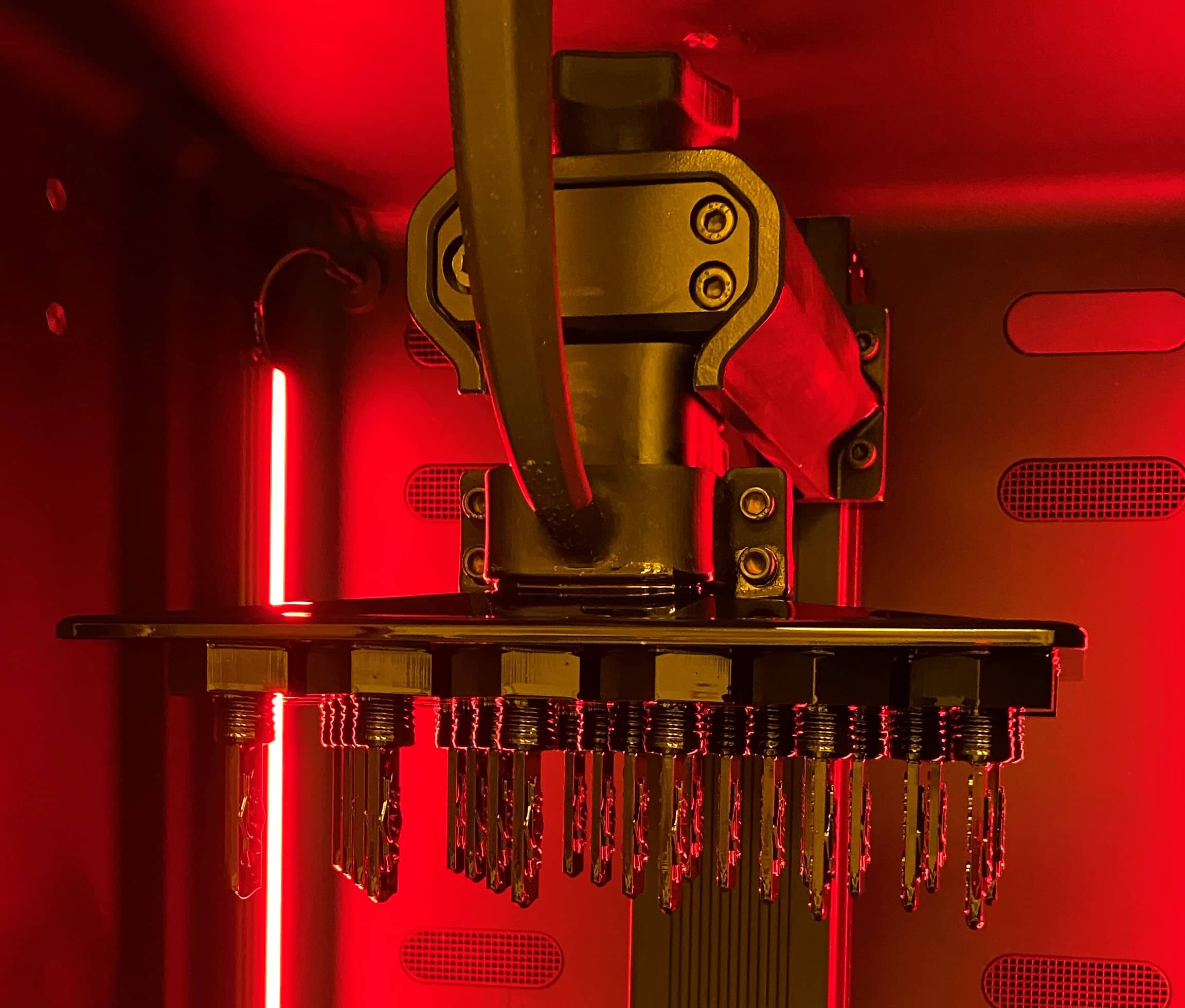

The parts I printed in these photos were done in BASF Ultracur3D ST 45 Black; that material is considered a general-purpose resin but I find it also tough and smooth – so smooth that we were able to print a threaded bolt with a reverse-threaded sleeve that unscrews to display fine lettering both raised and indented (shout-out to PADT’s new 3D Printing Application Engineer @ChaseWallace for the design). The ease-of-motion when assembling both parts is terrific.

In the first week of November, I’ll be headed to Stratasys headquarters for official hands-on training with the Origin One printer and a variety of materials. I can’t wait to print more parts that push the limits of surface finish, minimal support structures and end-use-part durability.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing/3D Scanning products and services. For more information on Stratasys printers and materials, contact us at info@padtinc.com.