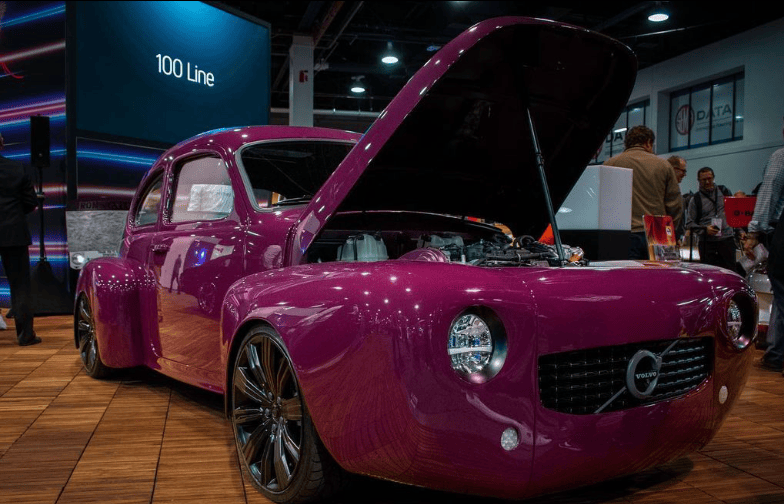

Something unique happened this past November at the SEMA 2022 automotive extravaganza in Las Vegas. Attendees witnessed the unveiling of a custom car-rebuild project, the Iron Maven, that incorporated an old car, a new car, 3D scanning and 3D printing, imagined and implemented by an all-female build crew. This was the third and most audacious hands-on learning project hosted by Bogi Lateiner, ASE master-certified technician, owner of Girl Gang Garage of Phoenix, Arizona, and TV host of Motor Trend’s All Girl Garage show.

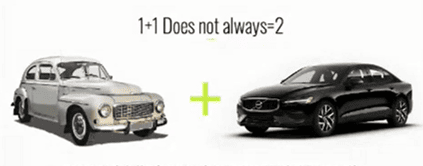

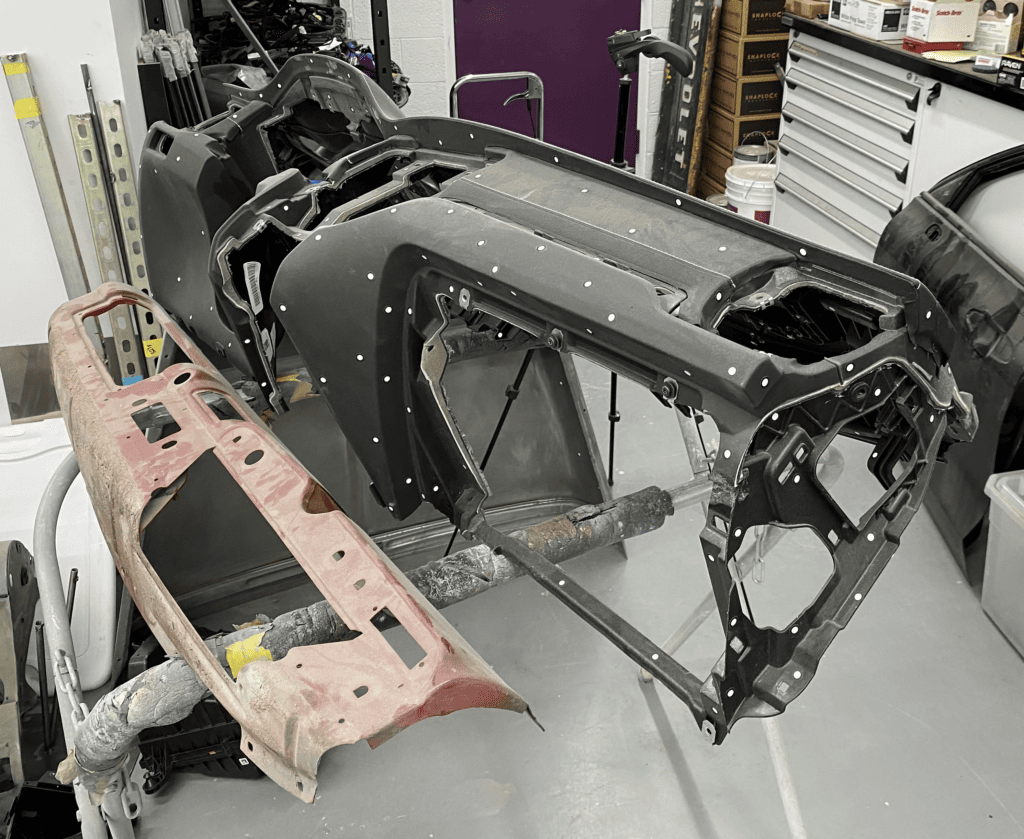

The Iron Maven vehicle is the merger of a 1961 Volvo PV544 body with the chassis, drive train, hybrid engine and modern electronics of a 2019 Volvo S60 T8 Polestar Engineered sedan, with the latter donated by corporate sponsor Volvo. Ongoing project-sponsor BASF (paints) was joined by Stratasys (3D printers) as they acknowledged the value in expanding Bogi’s work to bring more women into the automotive trades.

Even more exciting was the opportunity to super-charge Girl Gang Garage’s already awesome traditional hands-on car-rebuild skills with digitally-based possibilities, through 3D scanning and 3D printing. Stratasys loaned an industrial F370 FDM printer, materials, software and supporting equipment directly to the Garage, and Stratasys reseller PADT (Tempe, AZ) stepped in to train and offer advice on how to create prototype and end-use parts across a range of materials.

The project launched in January 2021, got sidetracked by COVID and supply delays, and finished better than ever in October 2022, as previously documented in these three PADT blog posts:

Girl Gang Garage: Custom Car Rebuilds + 3D Scanning + 3D Printing

Girl Gang Garage Iron Maven Project: Taking Shape, Moving Ahead

Girl Gang Garage: Iron Maven Custom Car Build and 3D Printing Update

Iron Maven Project Goals

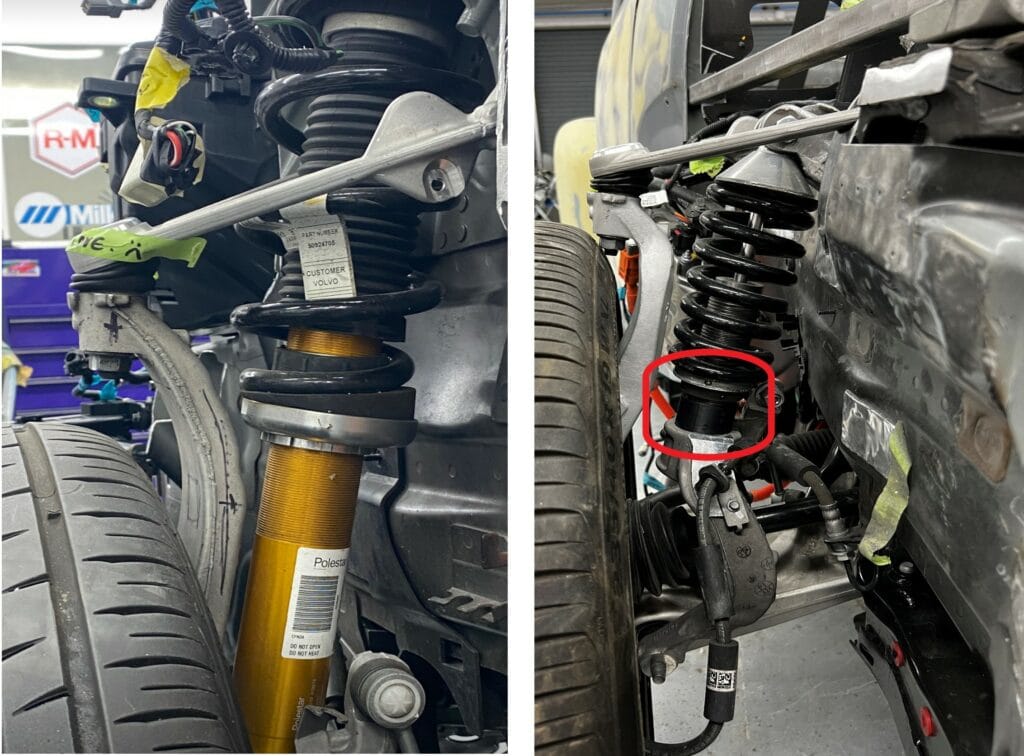

On the technical side, Bogi’s goals for the Iron Maven project were to utilize Volvo’s S60 Polestar platform to infuse the body of the PV544 with an all-modern Volvo drivetrain, suspension, and hybrid technology, while pushing the future of automotive innovation.

The custom rebuild also served two much broader purposes: create opportunities for women to try hands-on automotive tools at no cost (with any level of experience from newbie to expert), and be a catalyst for gender diversity in the male-dominated automotive industry. The experiences would both promote new career options and improve personal confidence in car ownership.

Along the way, the project would launch Girl Gang Garage into the worlds of 3D scanning, CAD-software modeling and 3D printing, allowing the team to merge old parts with new, and solve problems for which no hardware solutions existed.

Scan, Analyze, Design, Print, Repeat

Now that SEMA 2022 is over, you can appreciate the full extent to which the digital workflow was employed. It started with capturing the interior and exterior vehicle surface-geometry with a ZEISS TSCAN hawk handheld laser-scanner, then moved into the first of many tasks taken on by the Iron Maven CAD Tiger Team. This all-volunteer group, gathered from call-outs to both the Society of Women Engineers and Women in 3D Printing, comprised Felicia Greene (daytime job: Principal Engineer, Mechanical Engineering – Collins Aerospace), Cinthia Rodriguez (daytime job: Mechanical Engineer – Collins Aerospace), Kaila Spiller (daytime job: Landing Gear Design Engineer – Sikorsky) and Anne Pauley (daytime job: Mechanical Engineer – Google).

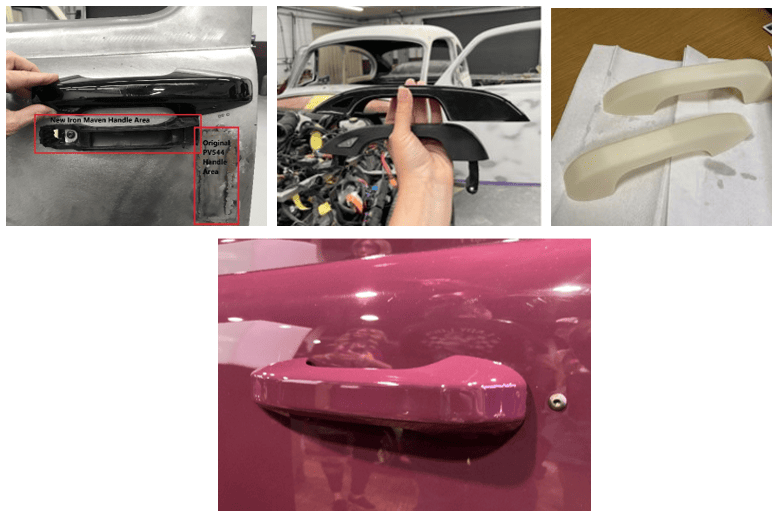

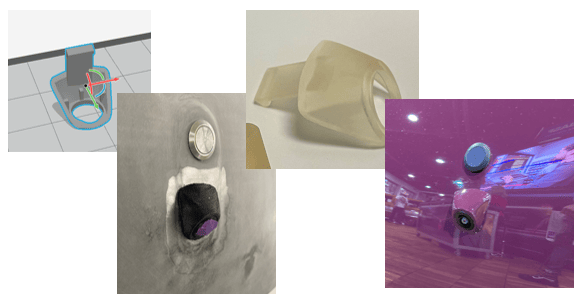

Rodriguez and Spiller got the project started during many virtual/remote design discussions, then Greene modeled the door-handle mechanism, generating the file for the first FDM printed prototype.

Pauley then connected Girl Gang Garage with the Autodesk Technology Centers Residency program, giving her, Bogi and other team members access to Fusion 360 software. This tool provided increased design flexibility which Pauley used over the next year to iterate multiple, totally new parts exactly sized for the unique Iron Maven structure.

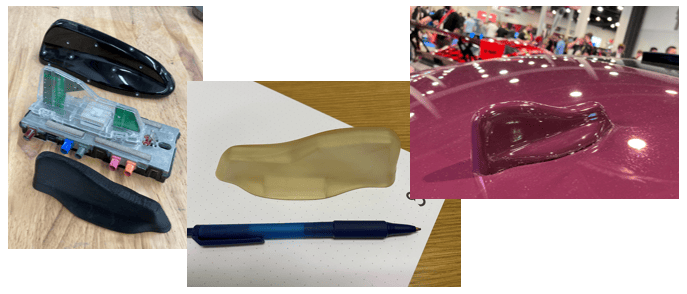

One example was the cover for the re-shaped door mechanism; Pauley first designed and printed a Stratasys FDM fit-check sample to verify the snap action, then multiple handle covers to get the external shape correct, then the final parts, printed in ASA then filled/sanded/painted with BASF’s custom paint. The paint color, chosen by an Iron Maven team vote, was dubbed Rebel Berry – appropriate for this one-of-a-kind project.

Two other redesigned parts were a new cover for the rear-facing camera (a feature that never existed on the PV544 but now needed to fit on the trunk), and a streamlined cover for the roof-mounted antenna. Here, two different Stratasys printers, the F370 filament system and an Origin One P3 DLP printer, played roles in the process, as Pauley generated a range of CAD models and zeroed in on the optimal dimensions. PADT helped Bogi with both the FDM fit-check parts and Origin final parts.

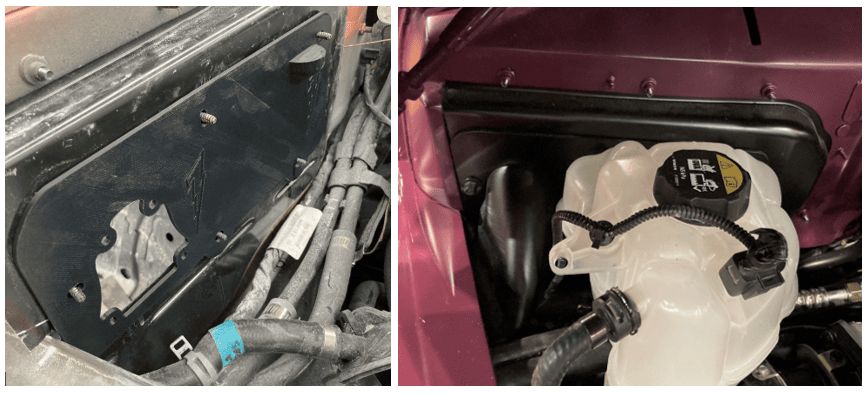

New Skills for Bogi’s Resume: CAD Designer and 3D Print-er

Always ready to try something new, Bogi quickly jumped in as the digital-workflow tools were presented to her. When Autodesk offered to visit on-site and hold a Fusion 360 training workshop, she was an A+ student and soon produced her first 3D model, a critical temporary ABS part that allowed work to progress on the car’s suspension months before the actual metal part was available. She also operated the F370 printer and helped Pauley figure out a way to redesign the washer-fluid reservoir mount and under-hood cooling duct, combining them on a single, custom mounting-bracket.

Oh, and about that S60 dashboard – you would never know Bogi took a Sawzall to it, removing almost nine-inches across two sections, remounting the touch-screen panel with audio controls, and fitting it all into that tiny PV544 interior.

It’s been quite the adventure for all of us at PADT, at Stratasys, and for the many members (more than 150 women!) who assisted with this extraordinary project. Stratasys has pledged to continue supporting Bogi and Girl Gang Garage, particularly with educational outreach throughout 2023, so look for more activity (and 3D printed parts) to come.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing/3D Scanning products and services. For more information on ZEISS scanners and Stratasys printers and materials, contact us at info@padtinc.com.