Problem: Your higher-ups require you to show photos of several new products in your marketing-communications efforts, so they can start selling hundreds or thousands. Or, they want you to show the products in a trade booth that measures just 10×10 feet.

Double Challenge: You don’t have the new products yet to show (not even one version) and some of them are far bigger than the booth.

Solution-that-avoids-Catch-22 (other than asking ChatGPT): Print full-color, clear and flexible 3D models using one or more of the five additive manufacturing technologies from Stratasys.

At Phoenix Analysis & Design Technologies (PADT), we encounter variations on this marketing communications dilemma quite often, so we decided to showcase how 3D printing solves three examples:

- Product needs to be shown in a variety of colors or patterns: earbud cases

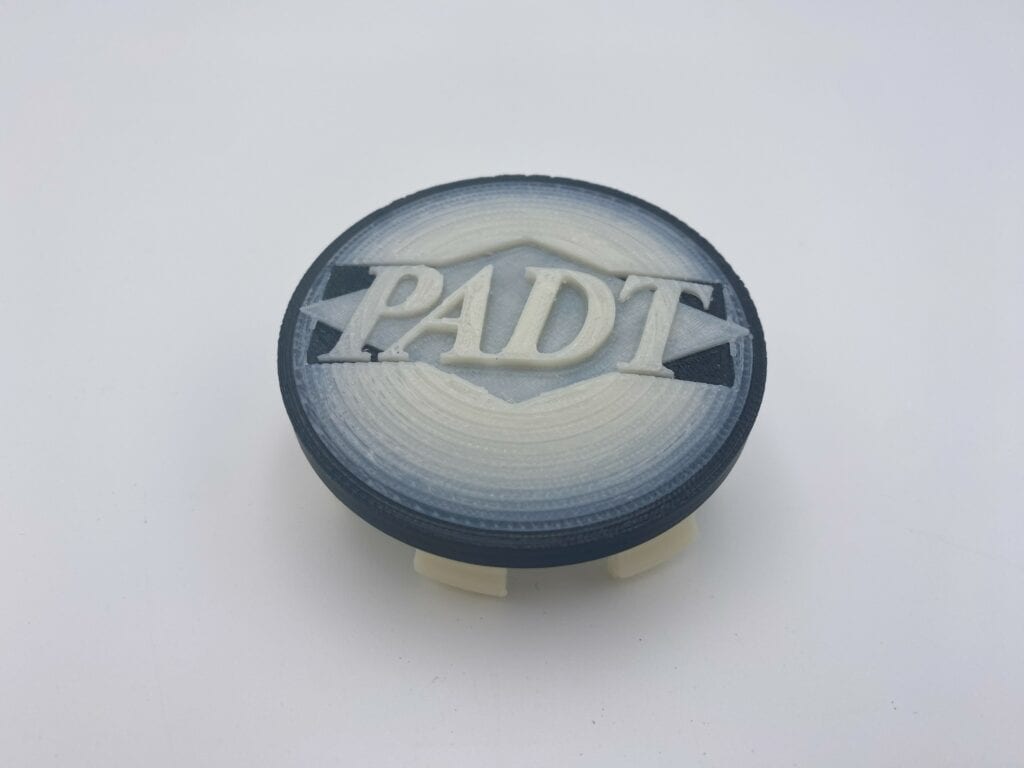

- Base product is customized for fit plus a custom logo: automotive wheel center-caps

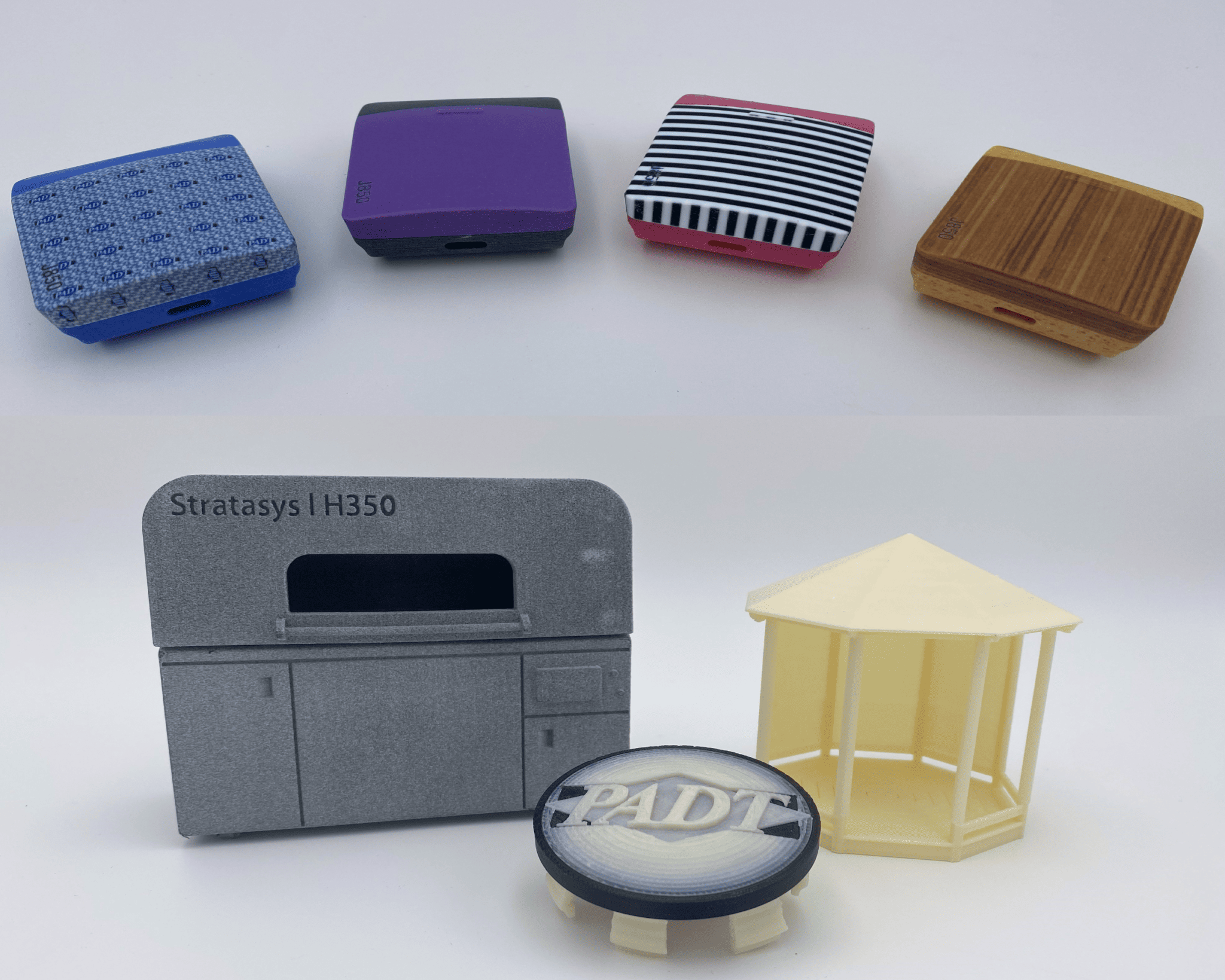

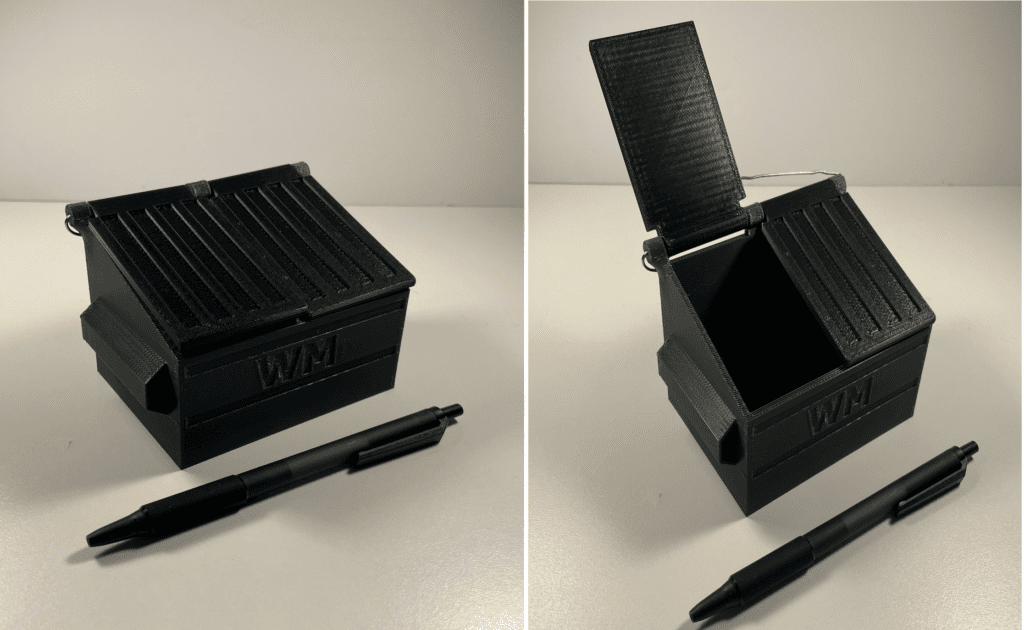

- Actual product is too large to economically mock-up but can be 3D printed in miniature: dumpster, inflatable boat, gazebo and model of Stratasys H350 printer

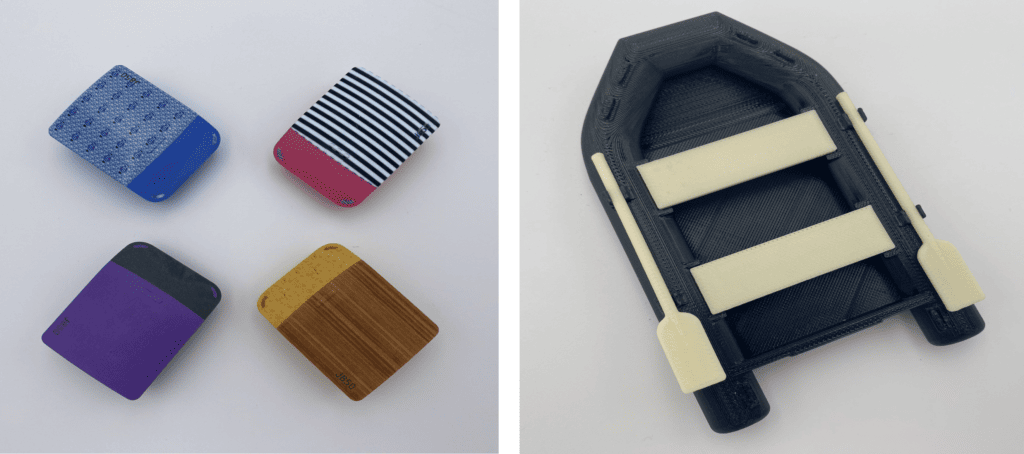

Product variety with full-color prints

With a Stratasys J55 or other PolyJet technology resin printer, you can print variations of parts to demonstrate the wide-ranging variety of colors, transparency, texture and added imagery available, to appeal to a large range of tastes. Here we designed and printed four versions of an earbud case with mixed patterns. The options included:

- Color combination of purple and dark grey

- Visual texture combination of walnut wood and tan cork

- Pattern combination of black/white stripes plus hot pink

- Added pattern-repeat with all-over PADT logos plus official company “blue” base

Only a full-color 3D printer with high resolution (600 dpi) printheads and color options that include Pantone matching can produce these high-quality sample parts all in a single build.

Custom versions suited to after-market products

The automotive after-market is filled with items for jazzing up your favorite vehicle. Here we used a Stratasys F370 industrial FDM printer with two different hot-swapped filament colors to highlight our design for a center-hub replacement on the original wheel.

Miniature printed parts that showcase large objects

Who doesn’t love the mini-version of some everyday item? Being able to 3D print a small but recognizable replica of a really large real-world part opens up many possibilities. You can bring these to tradeshows or directly to customers, or create an outstanding display case in the company lobby. Or, as mentioned before, you’ll be able to show product photos on social media long before the actual product has made it to the end of the assembly line.

Here we highlight four very different end-products, as well as several of the Stratasys technologies that make them possible.

Commercial dumpster model: You’ve never seen a dumpster looking this good! For this 3.5” x 2.75” part, we printed the lids in ABS Black on a Stratasys F370 FDM printer, and the base in ABS Dark Grey on a Stratasys F450 FDM printer.

Inflatable raft (rubber/rigid): This small model (about 5” x 3”) of a full-size inflatable dinghy (typically more than 8 feet long) takes advantage of the F370 FDM printer’s range of material options. The boat itself was printed in flexible TPU 92A Black, while the oars and seats were printed on the same system in rigid ASA (UV resistant) Ivory.

Gazebo Structure: A full-size gazebo for outdoor living, with base-platform and roof, could easily span 12 feet across and be 10 feet tall, yet our mini-gazebo only occupies 3.5” of space on a trade-booth table. Details show up nicely on this part printed on a Stratasys F370 FDM printer using ASA ivory.

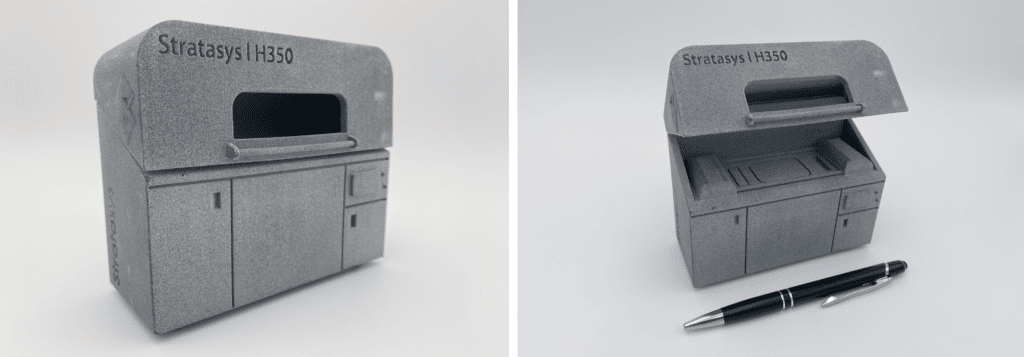

3D Print a Printer: Because why not? The full-size Stratasys H350 printer, which creates production parts out of such powders as Nylon 11 and Nylon 12 using SAF technology, measures 75” x 37” x 68”, while our mini-model clocks in just around 4.75” x 3” x 4”. Note the functioning hinged lid!

A model for every marketing communications purpose

So, when you need to generate models and photos for social media posts, product literature, account- manager samples or trade-show displays, think 3D printing. You’ll be able to print small, custom, colorful and unique designs that probably fit in your pocket, and definitely will delight both your customers and your upper management.