Enabling World Changing Product Innovation

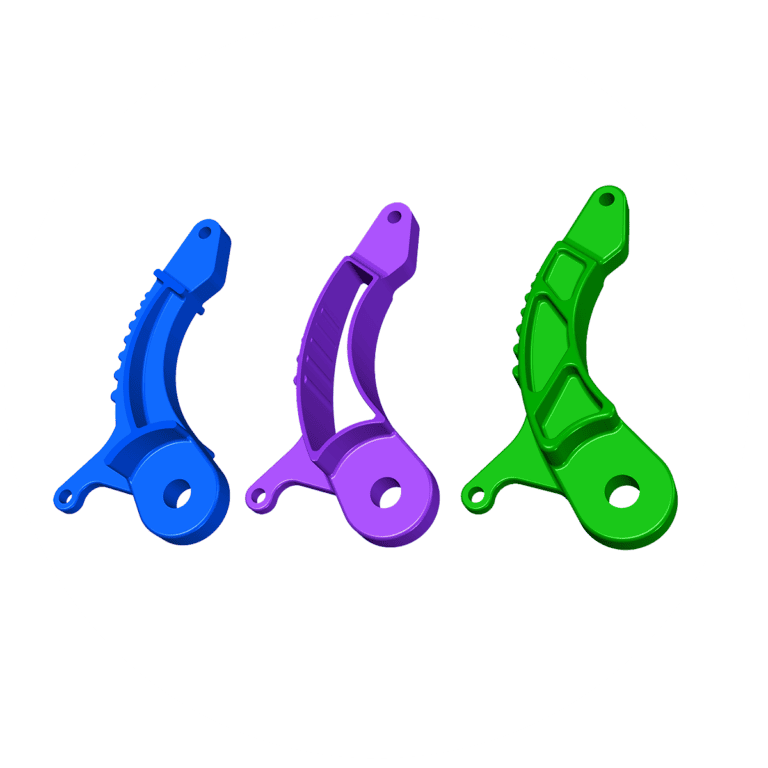

We start with engineering fundamentals, add in customer specifications, leverage our in-house design, simulation, test, and manufacturing, and tie it all together with flexible project management to bring your innovation to life.

More than a Black Box - A Part Of

Your Team

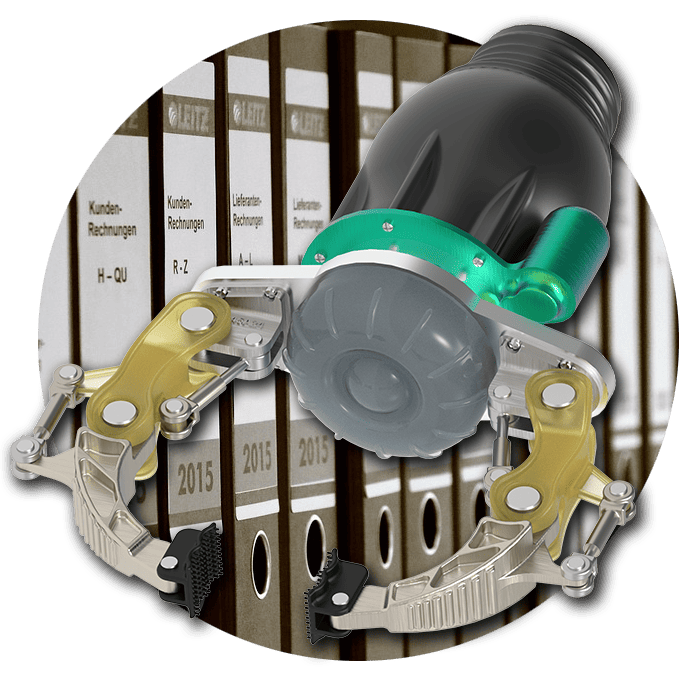

Most companies offering simulation services have a “black box” business model. You give them a problem statement, they give you a quote. You give them money, they give you a report. At PADT we look at simulation as a collaborative effort that begins with us working to understand what answers you are trying to find with your simulation. Once we understand that we will work with you to establish the right problem statement and a reasonable price.

Breadth and depth to address the full problem statement

Most companies offering simulation services have a “black box” business model. You give them a problem statement, they give you a quote. You give them money, they give you a report. At PADT we look at simulation as a collaborative effort that begins with us working to understand what answers you are trying to find with your simulation. Once we understand that we will work with you to establish the right problem statement and a reasonable price.

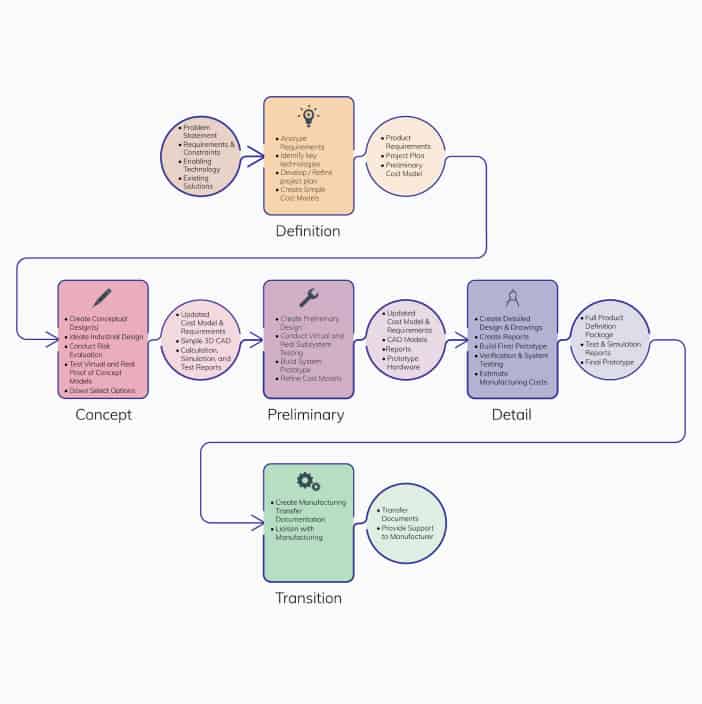

Our Process

Stage 00

Discovery

and Data

Stage 01

Ideation

Product Concept

Stage 02

Refine

Stage 03

Verification

Preliminary Product

Stage 04

Finalize

Stage 05

Validation

and Qualification

Stage 06

Production

Support Sales

Stage 07

Closeout

Industries

Our Product Development team is industry agnostic, we are all about bringing the best in design, engineering, and test to every industry and leveraging knowledge in one area for other verticals. Over the years, we have developed significant experience in a few key industries.

Medical Devices

Quality system awareness

Rigorous project management

Solar Power Systems

Diverse manufacturing knowledge

Strong focus on system efficiency

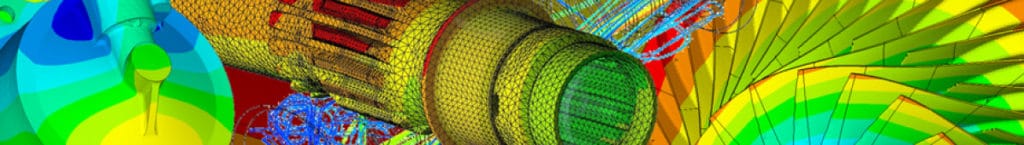

Rotating Machinery

Powerful multiphysics simulation

Fundamental familiarity with industry

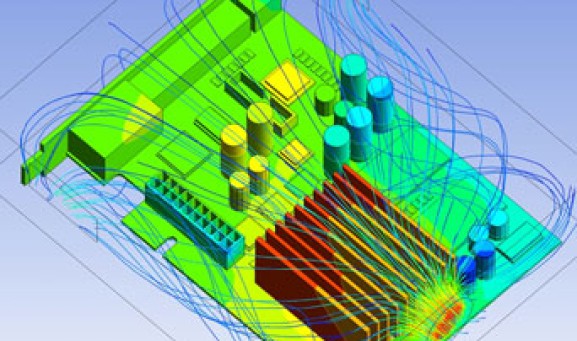

Eletronics Packaging

Robust thermal and mechanical simulation

Broad packaging experience across size and application

Manufacturing Machinery

Proven software/hardware integration

Comprehensive vendor pool

Advanced Agriculture

Consumer Products

Why PADT for Product Develoment?

Real-world experience in multiple disciplines and industries deliver greater creativity and faster problem solving

Flexibility, communication, and comprehensive processes deliver a project management system that allows innovative creativity while meeting challenging requirements and schedules

Developing products is often a balance between control and creativity. Cost, schedule, and resources often contradict the need for creativity in problem-solving and adaptation to unexpected challenges. Over the years, PADT has developed a project management methodology based on flexibility as well as frequent and open communication. Working as a team with the customer and vendors, or project managers plan, monitor, and manage in a balanced and adaptable way. This approach has proven to be extremely effective for our customers, meshing well with their internal processes and giving them the confidence that PADT’s team will meet schedule, budget, and performance specifications. All while still allowing for collaborative creativity that gets to those goals faster and often exceeds them. You can get a glimpse of our methodology when we work with you on preparing a proposal for your product development project, or we would be more than happy to refer you to one of our many long-term customers.

Diverse experience, tools, and resources enable the design of world-changing products

Need Assistance With Your SBIR/STTR Project?

Over the years, companies and universities have come to PADT to leverage our design, test, and simulation experience in support of their engineering for their SBIR and STTR grants. Our team supports the proposal phase with quotes, letters of support, and collateral information at no cost to you. After you are awarded your grant, we provide the resources you don’t have in-house. This usually includes the combination of simulation, project, management, design, prototype build, and testing you need to supplement your team. We focus on design for manufacturability and solving complex technical challenges, supplementing your domain expertise with our engineering experience and extensive experience running our own SBIR/STTR projects.

Contact us at consulting@padtinc.com to discuss the solicitations you are considering.

case study

Exploring Better Ways to Remove Wrinkles

Ultherapy is a non-surgical, non-invasive procedure for the face that uses high density, focused, ultrasound and the body’s own natural healing process

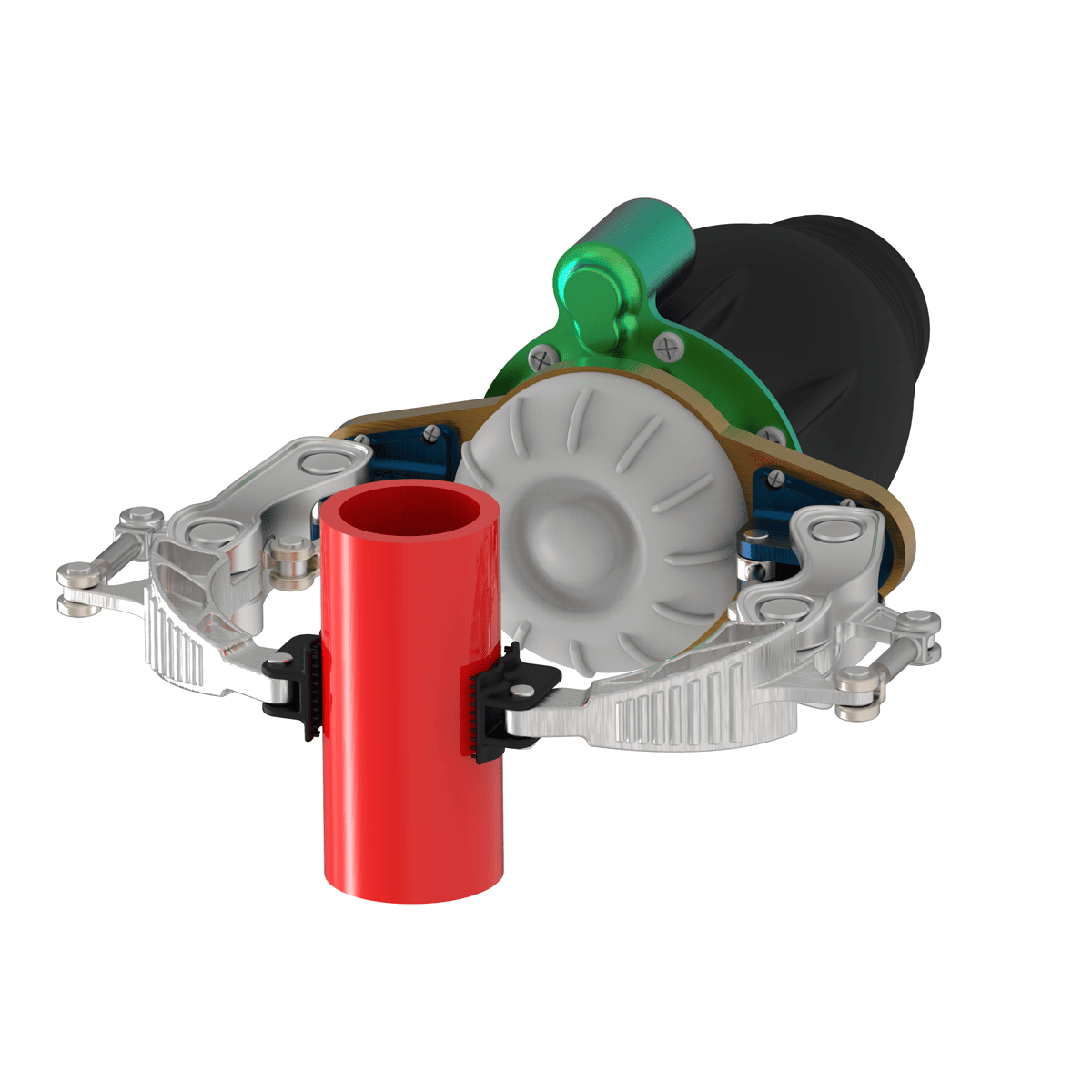

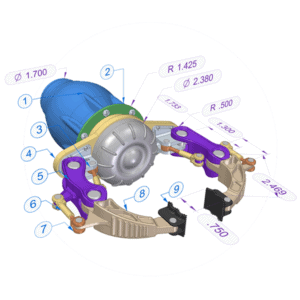

The existing Handpiece was functional, yet difficult and expensive to manufacture and service. The system also suffered from transducer-handpiece engagement issues that were complicated by component interface and tolerancing issues. PADT approached the redesign project using a multi-company, multi-disciplined team while working within our flexible, customer-specific, FDA compliant design control process.

“PADT has provided a number of valuable services for Ulthera® ranging from design work and ergonomic improvements, to manufacturability and V&V testing. Ulthera® also benefited from PADT’s adaptable, customer-specific, Design Control process to minimize the QC documentation requirements on the Ulthera® staff”

– Michael Peterson Vice President, R&D Ulthera, Inc

case study

Prooving Durability in a Life Saving Artificial Heart

Originally used as a permanent replacement heart, the SynCardia Total Artificial Heart is currently approved as a bridge to transplant.

PADT’s challenge was to translate SynCardia’s design requirements into a series of verification tests for the Freedom portable driver and meet a very strict delivery schedule. PADT’s medical device engineering staff worked closely with SynCardia’s engineering, QC, and regulatory personnel to translate design requirements into a series of successful verification tests.

“SynCardia has chosen to work with PADT based on their ability to develop close personal relationships, to create and implement engineering solutions rapidly, and to support SynCardia’s innovative drive for our lifesaving technology.“

– Douglas A. Nutter Chief Operating Officer SynCardia Systems, Inc.

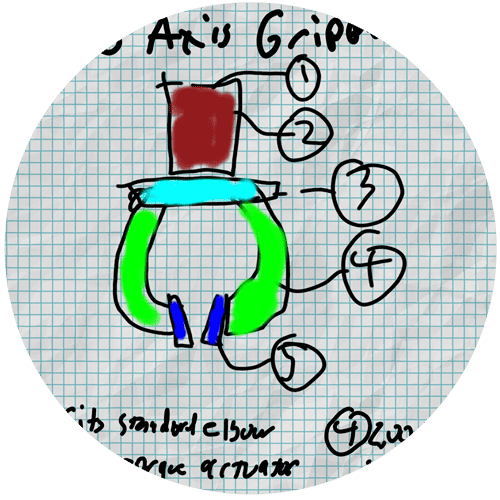

case study

Proving Feasibility for a Novel Tissue Expander

The tissue expander improves surgical access during minimally invasive surgeries by creating and maintaining, an enlarged surgical corridor through more gentle radial expansion instead of a downward stabbing motion.

PADT’s challenge was to develop a compelling prototype to prove the viability of the technology, and find out if the device could be packaged within an enclosure that would lend itself to the surgical environment ).

“I found there to be great benefit in going through PADT’s disciplined steps for the development of an updated prototype of our device. Restarting with a more systematic approach, and analyzing each component fresh, made me feel confident about every aspect of the new design.”

– Neil R. Crawford, PhD, Associate Professor, Spinal Biomechanics Barrow Neurological Institute

case study

An Electric Vehicle Quick Charger that is Fast and Stays Cool

Most charging stations require hours to recharge a vehicle contributing to the limited viability of electric vehicles. When introduced, the ECOtality Blink DC Fast Charger was the fastest method for charging vehicles; it used intelligent, user-friendly features to intuitively and safely charge electric vehicles in under 30 minutes. ECOtality approached PADT to develop the Charge Dispensing Unit (CDU), the customer-facing part of the world’s first Blink DC Fast charger. We utilized our in-house simulation expertise to assure reliable operation over a wide range of temperature, environmental, and operating conditions.

“PADT did a great job translating our prototype ideas into a fully-designed, manufacturable product. From multi-disciplinary engineering to project management to fabrication, PADT did it all. PADT worked collaboratively with our team to understand requirements and to solve technical hurdles in order to deliver a product that best fit our expectations.” – Garrett Beauregard, Senior VP of Engineering, ECOtality Inc.

case study

Zapping Wrong Way Drivers

RS Solutions was looking to develop a method to stop a wrong way driver (WWD) on the roadway ramp, by sending radio frequency (RF) waves into the engine compartment of the WWD vehicle. In Phase I of the SBIR, RS Solutions demonstrated an RF system can successfully cause engine fault, which will stall the motor and require the driver to restart the engine. Phase II of the SBIR expanded on the earlier work, looking to understand if this equipment could be effective across diverse vehicles and at differing speeds. Along with consultation for engineering and test practices, PADT has been able to aid RS Solutions in several innovative developments during this Phase II effort.

“PADT came aboard on this project at an early conceptual stage to help RS Solutions win the Phase I SBIR and continued to support the project through our Phase II work. The team at PADT made valuable contributions to the projects through the entire process.”

– Jay Berens Owner and President, RS Solutions

case study

Providing Out of This World Vibration Characterization

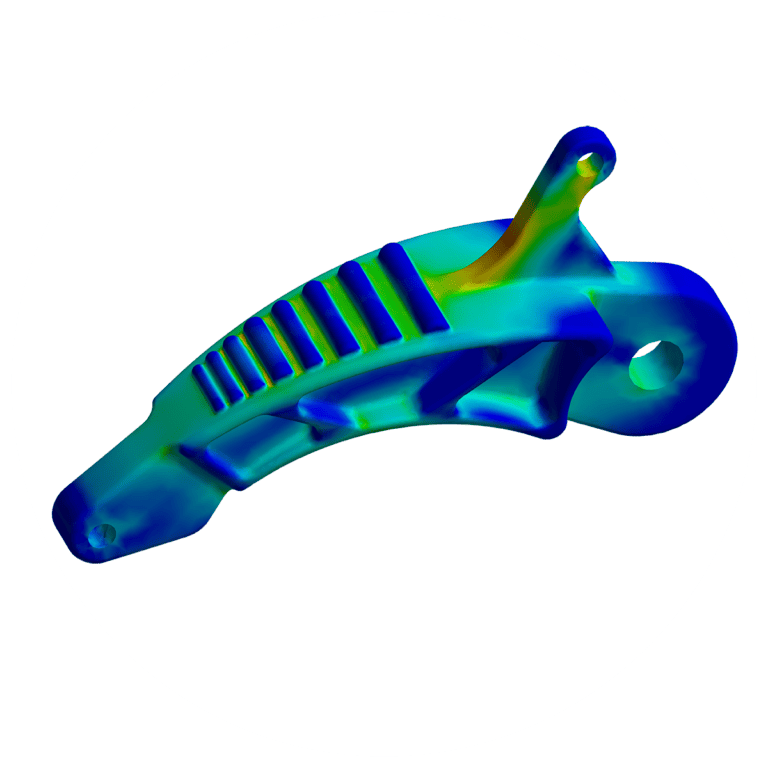

Altius Space Machines has been developing a system that enables transfer of anhydrous ammonia propellant between orbiting spacecraft. Within this system, they have a mission-critical and complicated valve assembly. Altius needed to understand how this assembly would behave from a vibration standpoint during launch. Altius’ and PADT’s goal during this analysis was to understand the resonant natural frequencies along with the excited modes and their relative energy present during launch of the assembly.

“PADT delivered above and beyond what was expected and worked closely with our team to support the entire process rather than just handing off a finished product. The end result was a realistic vibration simulation model that agreed well with tests, and a complete understanding of the results and process. Will be reaching out again and recommending to others.”

– Keith Drake, Test, Prototype, Facilities, and Operations Manager, Altius Space Machines

What our Customers are Saying:

Learn more about PADT's respected product development capabilities.

1-480-813-4884 |

Latest from our Product Development blog

Product Development – PADT

Product Development – PADT

- Product Development Lessons Learned: Scope Change is Going to Happen March 21, 2023

- Industry Highlight: PADT and Medical Device Development March 13, 2023

- Industry Highlight: PADT and Aerospace June 2, 2022

- Press Release: PADT Engineers Add Two Patents to the Company’s Patent List, Bringing its Total to 16 in the Last Two Years November 11, 2021

- Press Release: Expanding its Product Development Expertise, PADT Adds Dr. Tyler Shaw, Former Head of Advanced Manufacturing at PING, as Director of Engineering December 3, 2020

- What I use Most from my Engineering Management Masters Degree June 12, 2020

- Join PADT in Welcoming Jeff Wells, Business Development Manager, Engineering Services November 12, 2019

- Press Release: PADT Awarded U.S. Army Phase I SBIR Grant for Combustor Geometry Research Using 3D Printing, Simulation, and Product Development August 15, 2019

- Talking Hydrogen Fuel Cell Blowers for Trucking at the Governor’s House July 11, 2019

- Press Release: 2019 Commercial Vehicle Cleantech Challenge Selects PADT to Showcase Fuel Cell Blower Technology June 27, 2019