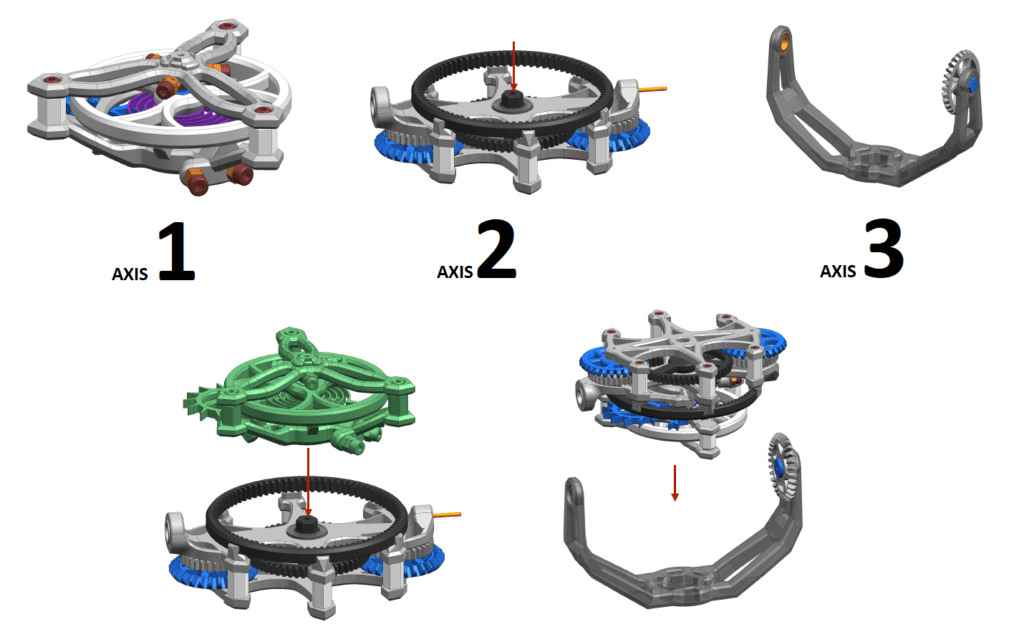

A year ago we highlighted the beginnings of an unusual project undertaken by PADT’s Senior 3D Printing Service Technician, Justin Baxter, in the post Three Dimensions of Time, featuring an enlarged, 3D version of a Tourbillon watch mechanism. That post showed the first (test version) of three subassemblies that would come together after literally hundreds of hours of printing and assembly work to comprise a working three-axis clock.

For a bit of background, an excellent write-up on this concept is on MyMiniFactory, which is also where you’ll find the complete description of the 3D-printable Tourbillon clock from a designer called Mechanistic. Check out this mesmerizing video of his clock in action. Mechanistic has previously done other awesome designs but this one is truly astounding in the level of detail required for both printing and assembly.

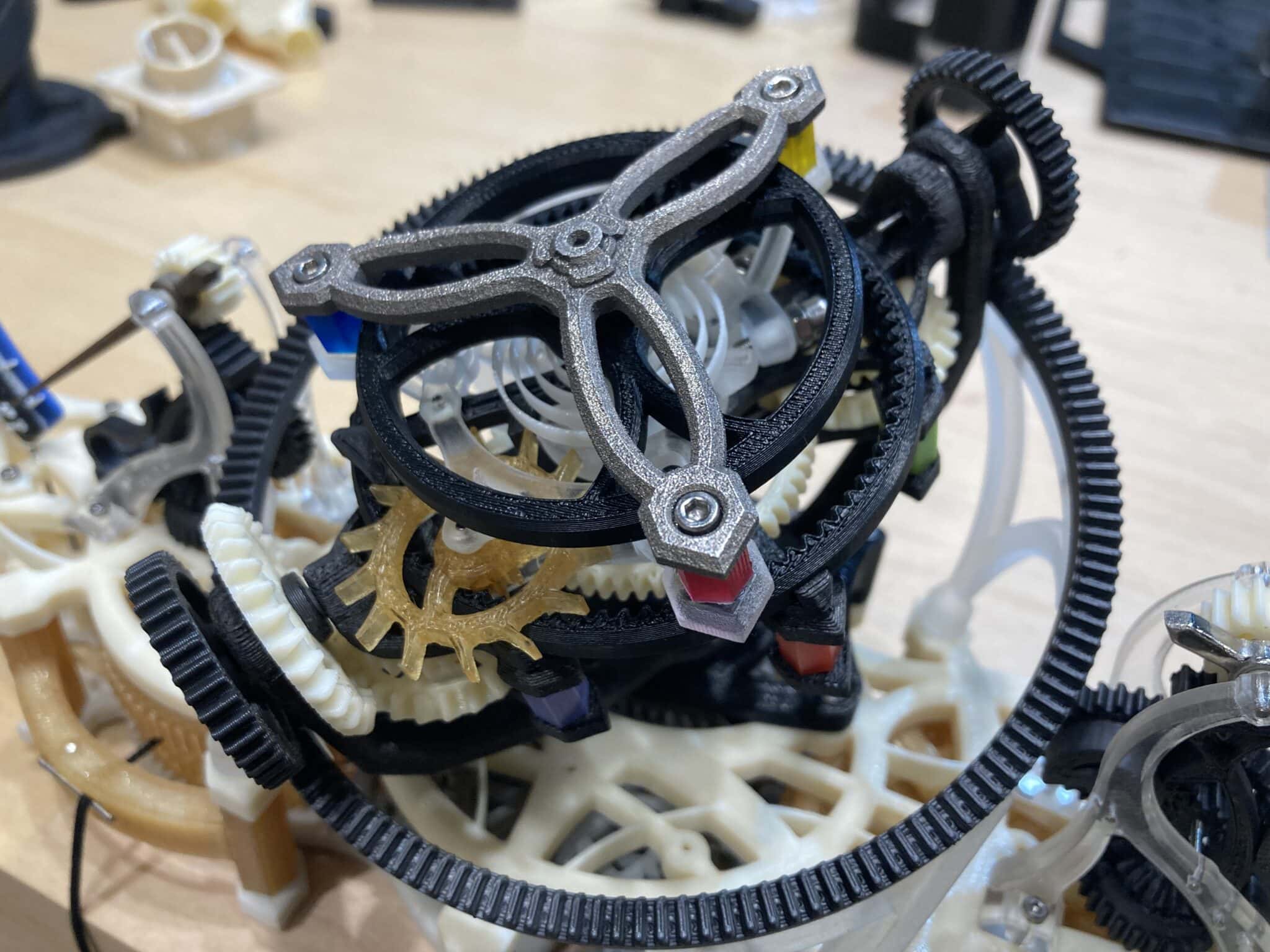

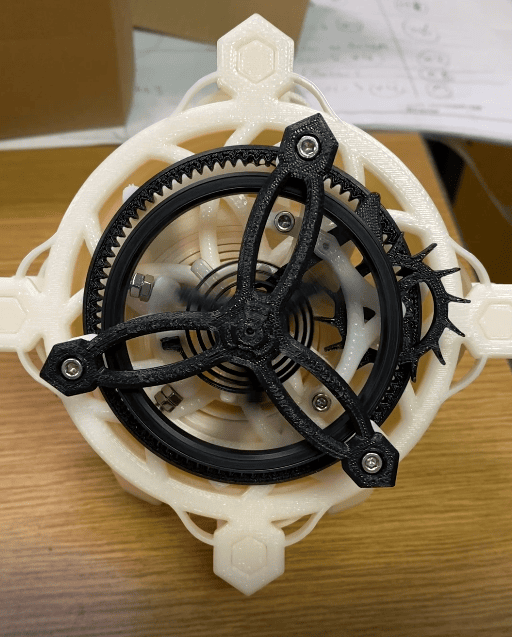

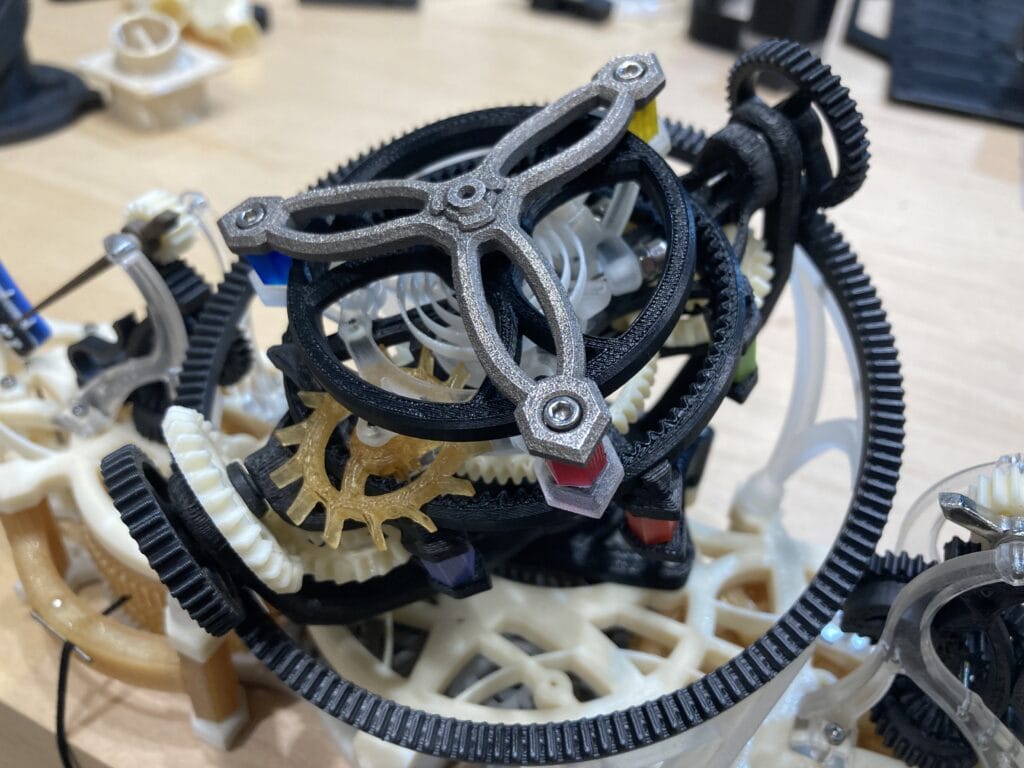

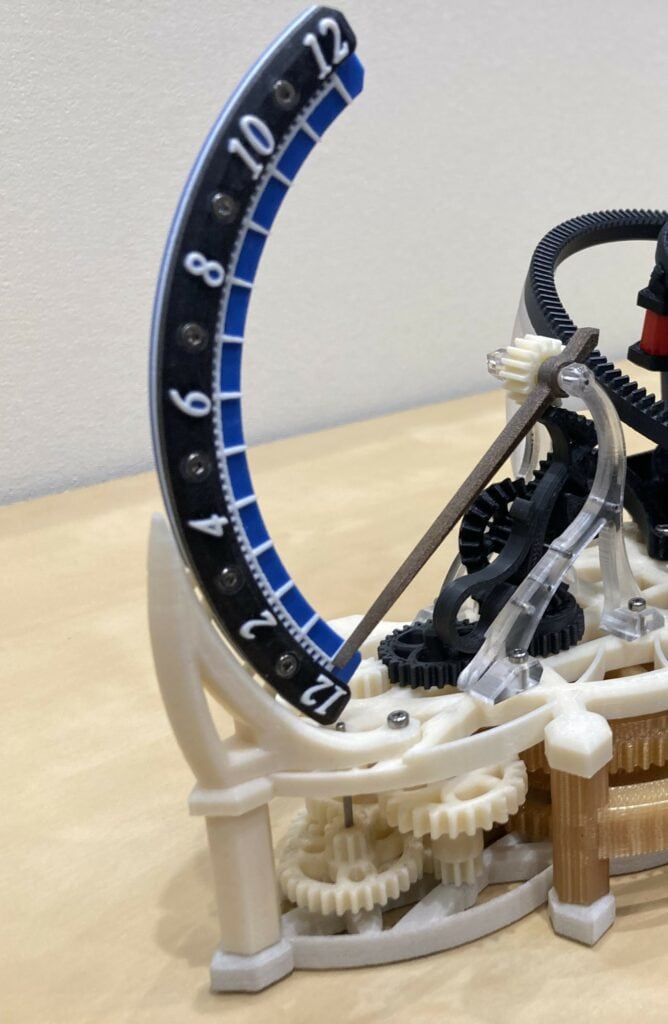

Now, check out the PADT version, complete and equally (if not more) awesome.

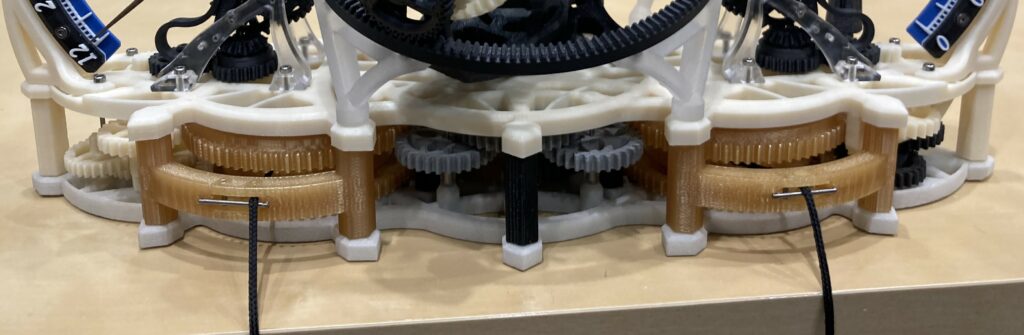

Justin recently set up the clock in the PADT Tempe, Arizona Demo Room so visitors can enjoy examining the more than one hundred 3D printed components, ranging from the wind-up key to the colorful standoffs to the custom-designed pendulum weights. The latter elements replace the original mainspring, increasing the clock’s runtime between rewinds. (We told you Justin knows a thing or two about the fine art of horology!)

The Tourbillon clock part production took advantage of almost every 3D printer PADT operates, spanning four of the seven ASTM standard AM technologies:

- Fused Deposition Modeling (Stratasys FDM material extrusion),

- PolyJet (Stratasys photopolymer material deposition),

- Powder Bed: Selective laser sintering (3D Systems SLS polymer powder bed fusion) and Direct metal laser sintering (EOS DMLS metal powder bed fusion), and

- Vat Photopolymerization: Stereolithography (3D Systems and UnionTech SLA) and Digital light processing (Stratasys Origin One P3 DLP).

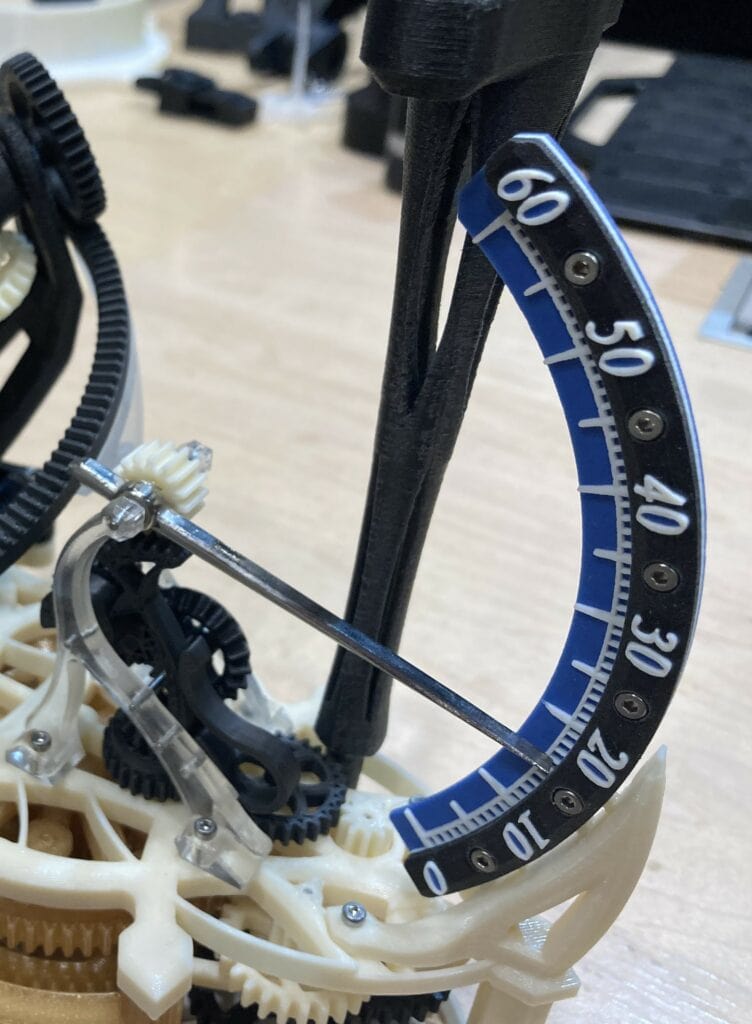

The project took advantage of several dozen material types, colors and secondary processes, which show up in the colorful stand-offs, metal pointers and clear brackets – some opaque, some translucent and others either as-printed or heat-treated.

The largest diameter gear and the two driving gears that ride on it were printed in Diran, a Stratasys FDM material similar to Delrin. The larger gears in the base are ULTEM 1010, the smaller ones ABS and ASA, the third-axis arm and second-axis “bridge” are Nylon 12CF, and the wind-up key was also printed in Nylon 12CF. The top section to Axis 1, with three radiating arms, was printed in aluminum on the EOS M290 laser powder-bed system.

Stratasys Quality Simplifies Clock Assembly

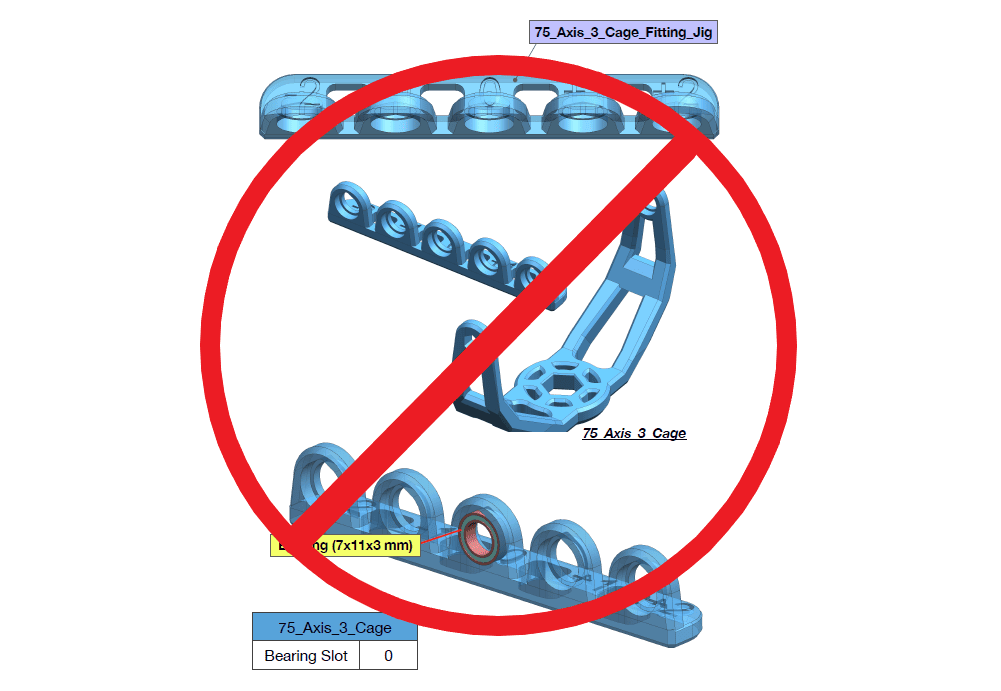

The instructions for printing and assembling all the clock components fill a 125-page document, and even include a section called Ultra Critical Print Parts. Here, the author cautions, “In order to avoid re-printing the same part over and over again to obtain the best fit, I’ve created fitting jigs which (are) essentially a clone of all bearing assembly features with varying dimensions. Print all fitting jigs using the identical printer, filament, nozzle size and print settings that you intend to use for the actual part. Insert bearings into the respective slots and identify the best fit slot number.”

I asked Justin if he did this and how it all worked out. His reply: “I did not print any of the test-fit fixtures, I printed only the “zero” parts and they all fit perfectly. The Stratasys machines are accurate enough that it wasn’t a concern; even when assembling different materials printed on different machines, the tolerances were spot on and needed no adjustment.”

This fits-right-first-time accuracy (detailed in the public Stratasys report, “FDM System Repeatability and Reliability Report – White Paper”), allowed Justin to leapfrog many pages of instructions and save hours of unnecessary trial-and-error printing. He says truly the most time-consuming part of the project was measuring and cutting tiny steel rod-stock sections to create the custom pins.

PADT Inc. is a globally recognized provider of Numerical Simulation, Product Development and 3D Printing/3D Scanning products and services. For more information on Stratasys and EOS printers and materials, contact us at info@padtinc.com.