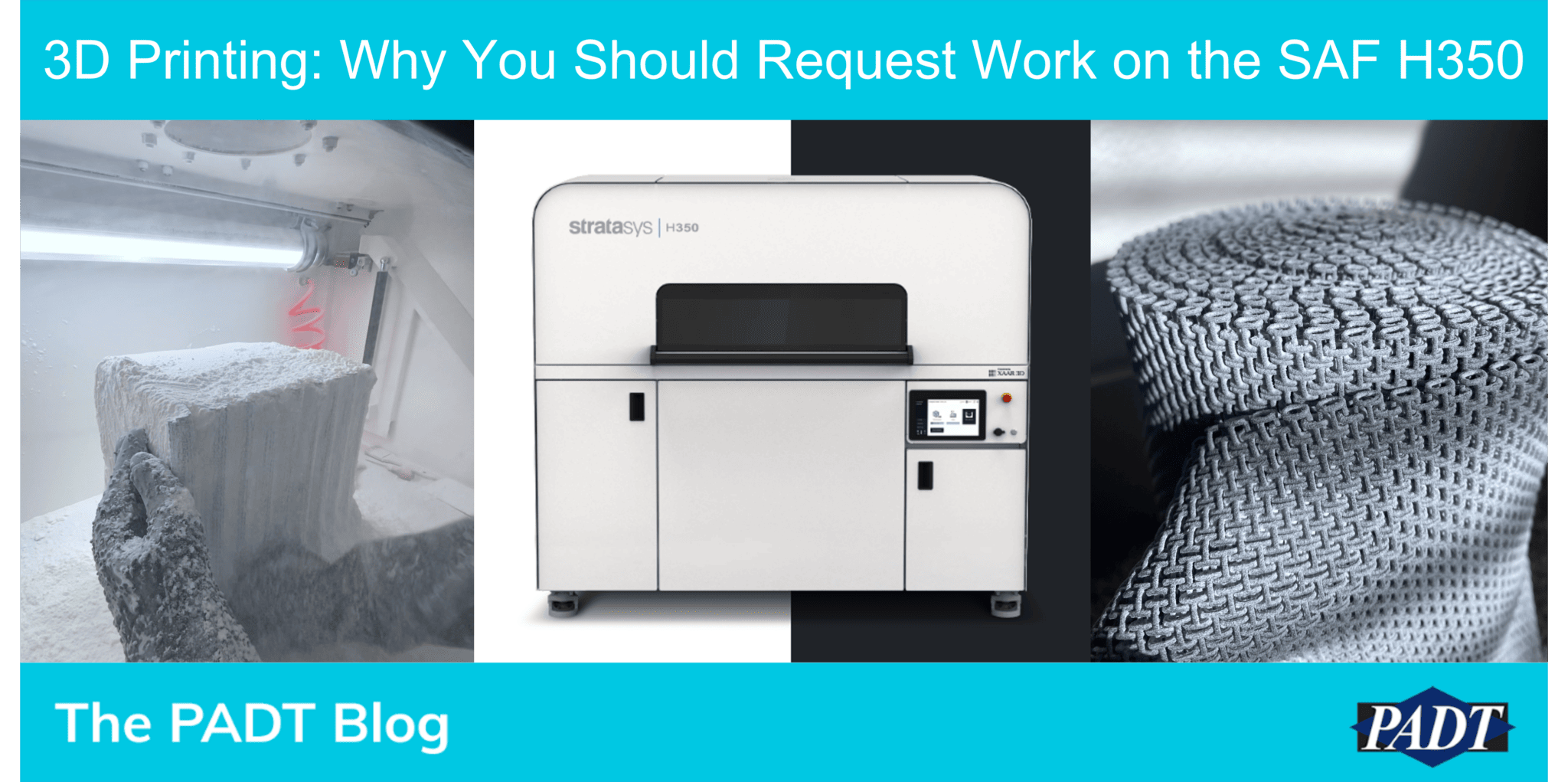

Imagine receiving 3D printed parts with unparalleled precision, lightning-fast speed, and cost-effectiveness that exceeds expectations. Welcome to Part 3 of our 3D printer series, where we introduce you to the newest technology in additive manufacturing: The Stratasys H350. This 3D printer, a personal favorite, is advertised as ‘High Volume. High Accuracy. Low Cost.’, but let us tell you, it goes beyond what the advertisements say. The H350 uses revolutionary (and recyclable) Selective Absorption Fusion (SAF) technology. Layer-by-layer, infrared-sensitive High Absorption Fluid (HAF) melts and fuses particles of polymer powder together. So, keep reading, in this blog we will delve into the remarkable capabilities of the H350, the amazing properties of its materials, and a cost-effective analysis!

What’s Best About SAF Technology

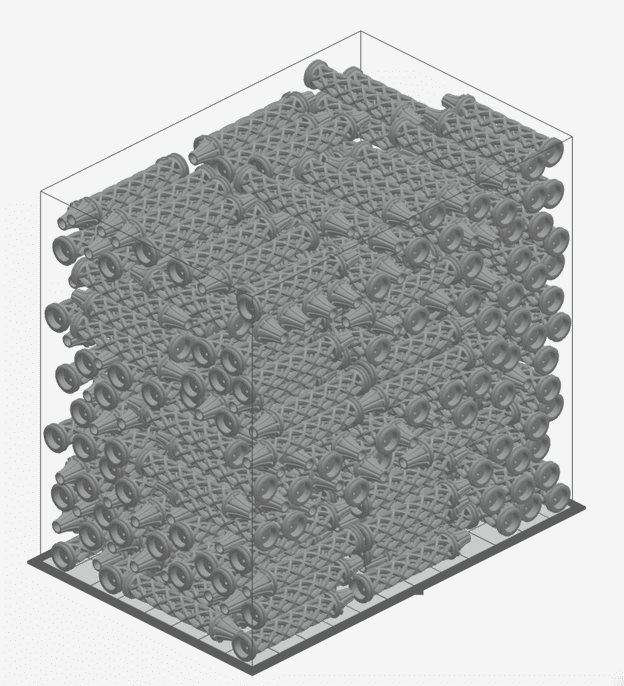

The SAF H350 is an innovative 3D printer that utilizes Selective Absorption Fusion (SAF) technology, allowing for high-speed, high-quality prints. This technology works by “selectively” fusing powdered materials using an infrared absorbing ink, resulting in precise and durable parts. Another great feature of the H350 is its recyclability. What does that mean? The unused polymer powder from previous prints can be collected, recycled, and reused in the following printing cycles. This not only contributes to greener manufacturing but also helps lower production costs (win-win for everyone). Moreover, another big advantage of SAF technology is the significant reduction in build time compared to the traditional powder bed technology, Selective Laser Sintering (SLS). Unlike SLS, where a small laser needs to fuse each layer individually, SAF build time is solely dependent on the build height, allowing for fully packed builds that still finish overnight. In fact, the maximum build time is about 13 hours. This is because the printing happens in 1 sweeping motion per layer over the traditional SLS’ small laser. Along with those key advantages, here are some highlights:

- Build volume of 12.4″ x 8.18″ x 11.53″

- Features can be built as small as 0.5 mm

- Wide range of industry applications

- Maximum build time ~13 hours

- Quick turnaround

- Cost-effective

Comparing Materials: PA11 & PA12

Advantages of PA11:

- High impact & fatigue resistance

- High nesting density (can fit more parts in each build)

- High ductility

Advantages of PA12:

- Superior chemical resistance

- Excellent thermal stability

- More rigidity

How Do PA11 and PA12 Chemically Differ?

- Melting point

- Moisture absorption

- Mechanical properties

- Thermal stability

- Rigidity

PA11 and PA12 have several chemical differences. Firstly, PA12 has a higher melting point, making it more suitable for thermal stability. Additionally, PA11 has a higher moisture absorption capacity due to its greater number of amorphous regions, affecting dimensional stability and mechanical properties in humid environments (Oliver-Ortega et al., 2018). These variations make each material better suited for specific applications. PA11 is known for its excellent mechanical properties, including high impact resistance and flexibility, making it ideal for functional prototypes, tooling, and jigs. On the other hand, PA12 offers superior chemical resistance, thermal stability, and stiffness, making it suitable for aerospace, electronic housings, industrial tooling, and more.

Pricing & Time Estimates: Cost-Effectiveness Analysis

Now to answer, “How much will this cost and how long will it take me?”. Using PA11, we will answer the questions everyone wants to know. A reminder that this is to give an idea of what pricing is like, and the total cost will always depend on project specifics, such as size, qty, etc.

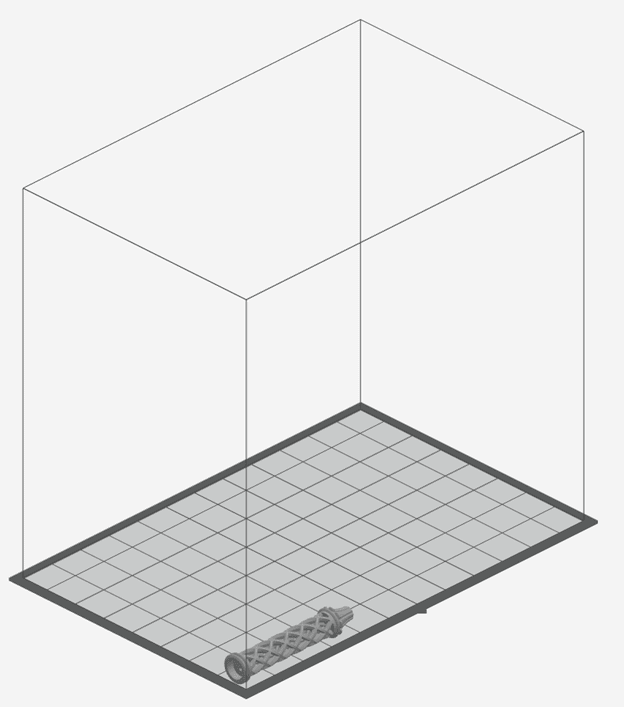

1 Part with PA11

- Time: 2-3 days

- Cost Per Part: $75

- Total Cost: $75

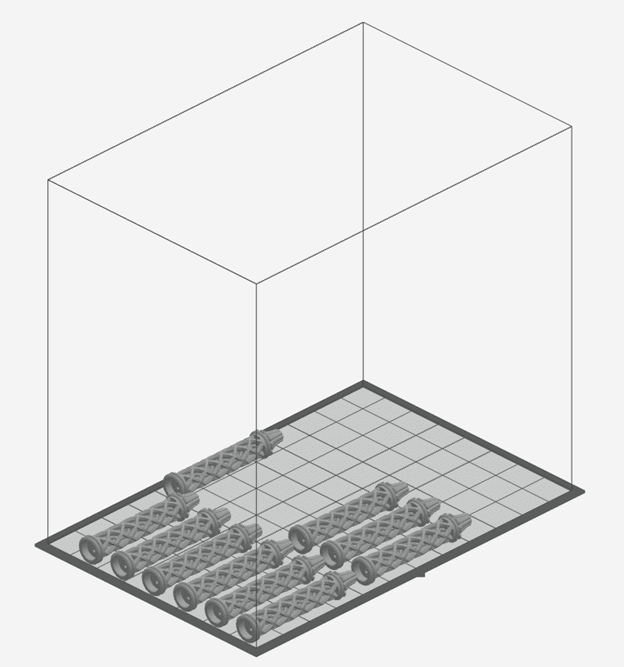

10 Parts with PA11

- Time: 2-3 days

- Cost Per Part: $17.60

- Total Cost: $176

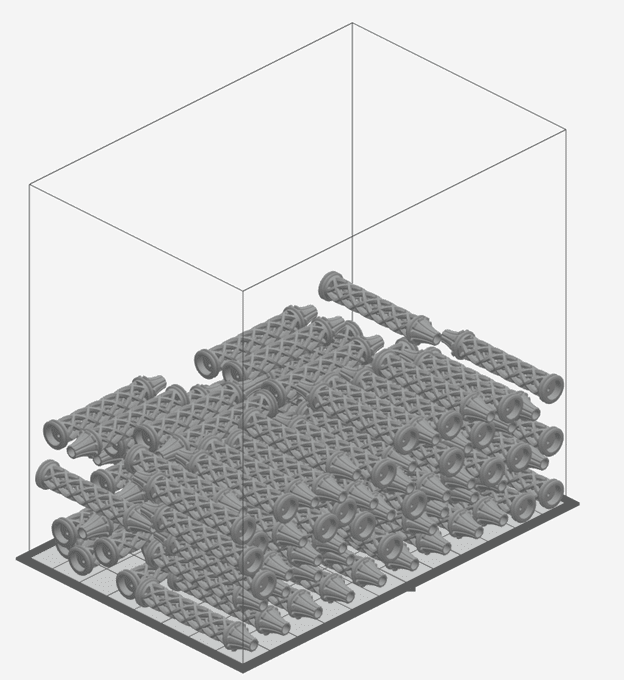

100 Parts with PA11

- Time: 2-3 days

- Cost Per Part: $15

- Total Cost: $1500

1 Filled Platform with PA11

- Time: 2-3 days

- Cost Per Part: $15

- Total Cost: $4485 (299 parts)

In conclusion, the Stratasys SAF H350 stands out as a cutting-edge 3D printer that offers exceptional capabilities. With its high-speed, high-quality prints enabled by Selective Absorption Fusion technology, it sets a new standard for precision and efficiency. If you’re interested in learning more about this series, be sure to check out Part 1 “Why You Should Request Work on the Neo450” and Part 2 “Why You Should Request Work on the Origin One”. If you have any further questions about whether the SAF H350 is the right fit for your project, reach out to us at 3dprint@padtinc.com! We are here to assist you and provide personalized solutions based on your unique requirements.

Follow us on Instagram for more 3D Printing and 3D Scanning content!

Source:

Oliver-Ortega, H., Méndez, J. A., Espinach, F. X., Tarrés, Q., Ardanuy, M., & Mutjé, P. (2018). Impact Strength and Water Uptake Behaviors of Fully Bio-Based PA11-SGW Composites. Polymers, 10(7), 717. https://doi.org/10.3390/polym10070717