The J55 Prime 3D printer introduces full color, high fidelity with tactile, functional and sensory capabilities – making the efficiency and quality of PolyJet Technology more affordable and office friendly than ever before. Create everything from quick design iterations to high quality final prototypes, all in a compact, quiet, and odorless process.

Unrivaled Accuracy, Realism and Functionality – Materials and software combine to create human anatomy models

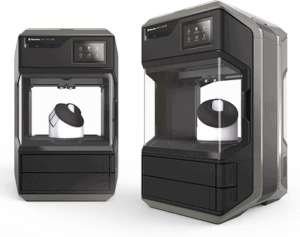

An affordable industrial-grade 3D printer that produces small to medium parts with consistent accuracy and repeatability.

Materials

You probably love your Stratasys 3D Printer or Production System. It is reliable. You count on it to be ready when you need it.

Implementing Additive in a New Direction

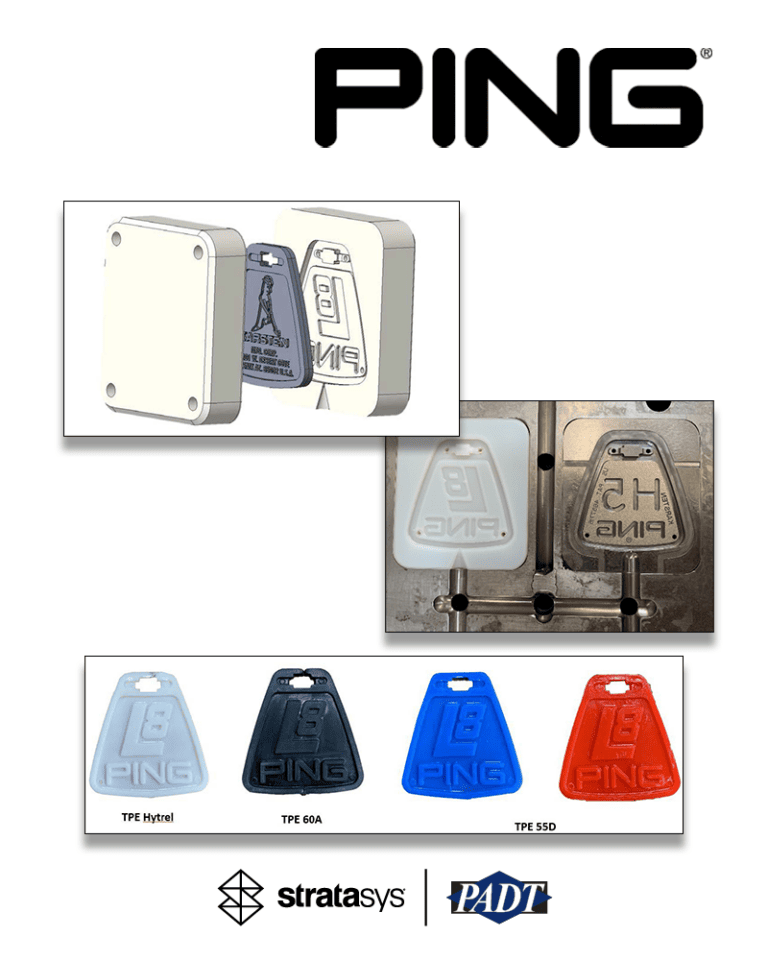

Always on the lookout for new ways to optimize their workflow, PING recently set out to find new technologies that could be used to further speed up and reduce the costs of its development processes. Additive manufacturing has been used at PING for over 20 years in various capacities, so investigating developments in that field was a logical next step. The company set out to pinpoint specific stages in its process through which implementation would benefit the entire manufacturing organization.

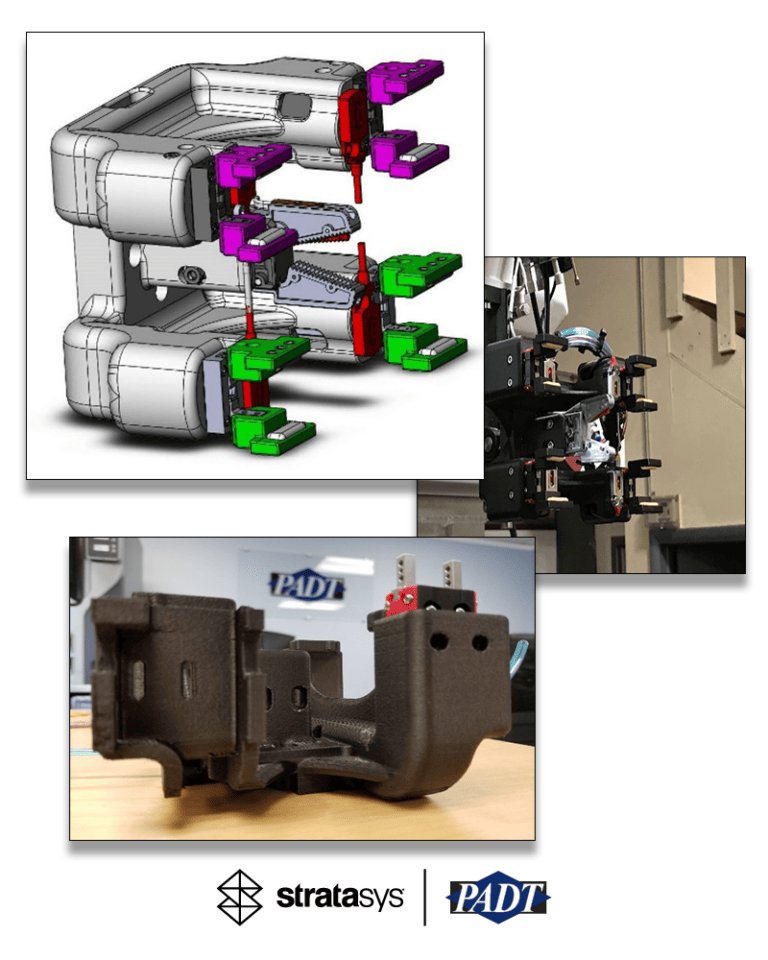

Robotics and Their Role in the Factory of the Future

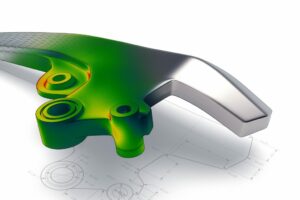

In the factory of the future, automation is king. Manufacturers can drastically reduce lead times, reduce labor costs, and increase overall efficiency through the use of robotics at several stages in their workflow. These machines serve a variety of functions on the factory floor, including everything from gripping and positioning parts to welding and painting assemblies in the later stages of the manufacturing process. While each function serves a unique purpose specific to the task it will perform, they all utilize an essential component known as End-of-Arm tooling (EOAT).

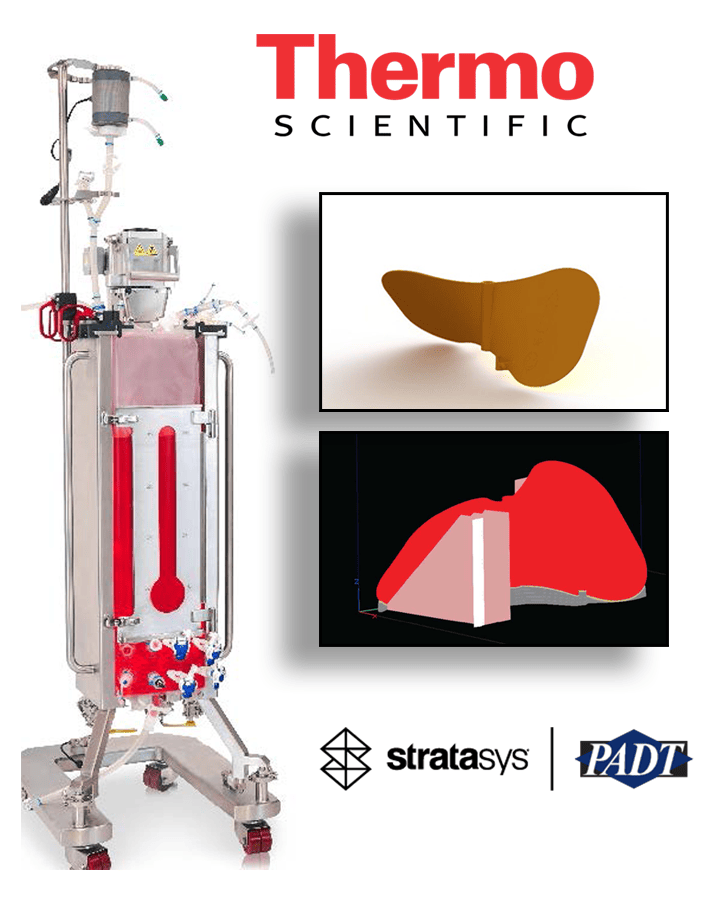

Developing Hardware for Biomanufacturing

The production of pharmaceuticals, vaccines, and antibodies is a highly intricate and innovative process that relies on technology matching its level of complexity. The vessels used in the procedure, called bioreactors, are designed to carry out the required chemical processes key to this industry. Inside is a tank in which growing organisms are submerged and suspended in a liquid solution where they can perform their desired function with limited production of impurities. In order to ensure a consistent, high-quality output, bioreactors are designed to control internal environmental factors such as temperature, nutrient concentrations, pH, and dissolved gases; all of which can drastically affect the growth and productivity of the contained organisms if not carefully regulated.

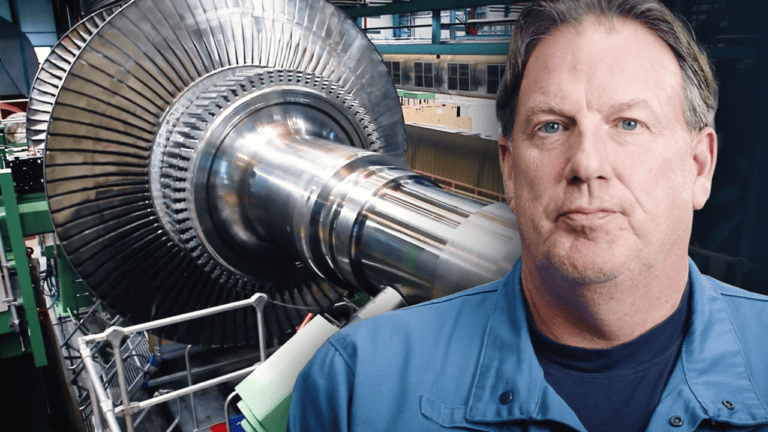

Using 3D optical scanning to reverse engineer industrial turbine spare parts

Meet Johan, director of Energetic Machinery in Belgium, and experience his passion for industrial steam turbines. Their company repairs and replaces turbomachinery components. They use optical 3D Scanning to capture existing geometry and reverse engineer replacement parts or plan their refurbishment. The portable nature of the GOM and ZEISS optical scanners allows them to go to the customer site accurately capture geometry.

Energetic Machinery is a classic example of how manufacturing companies across industries leverage #HandsOnMetrology to drive their reverse engineering efforts.

3D scanning helps in the creation of perfectly flush frames and in complex assemblies.

Meet Olivier from E-bike manufacturer Cowboy in Brussels. The company’s aim is to manufacture urban mobility solutions that offer amazing design, seamless usage, and affordability. At cowboy, they are pushing the boundaries of design, including a completely flush assembly even though it consists of different components. To achieve the precision they need, they leverage the power of 3D Scanning to capture their complex surface. That information is used to improve the design and make quick design iterations.

When we bought the Replicator series, it gave students more exposure to the technology, which resulted in increased interest and use.

Preparing students with the knowledge, skills, and resilience to embrace their future has always been at the crux of Abingdon School, an independent day and boarding school for boys, in Oxfordshire, England.

The school’s Design and Technology department offers a range of product design courses that aim to develop students’ technical knowledge and proficiencies. 3D modeling and design are taught alongside traditional manufacturing methods using woods, metals, and polymers.